Low-temperature sintered terracotta blank and preparation method thereof

A technology of low-temperature sintering and tile billets, which is applied in the production of ceramic materials, clay products, and other household appliances. low temperature effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

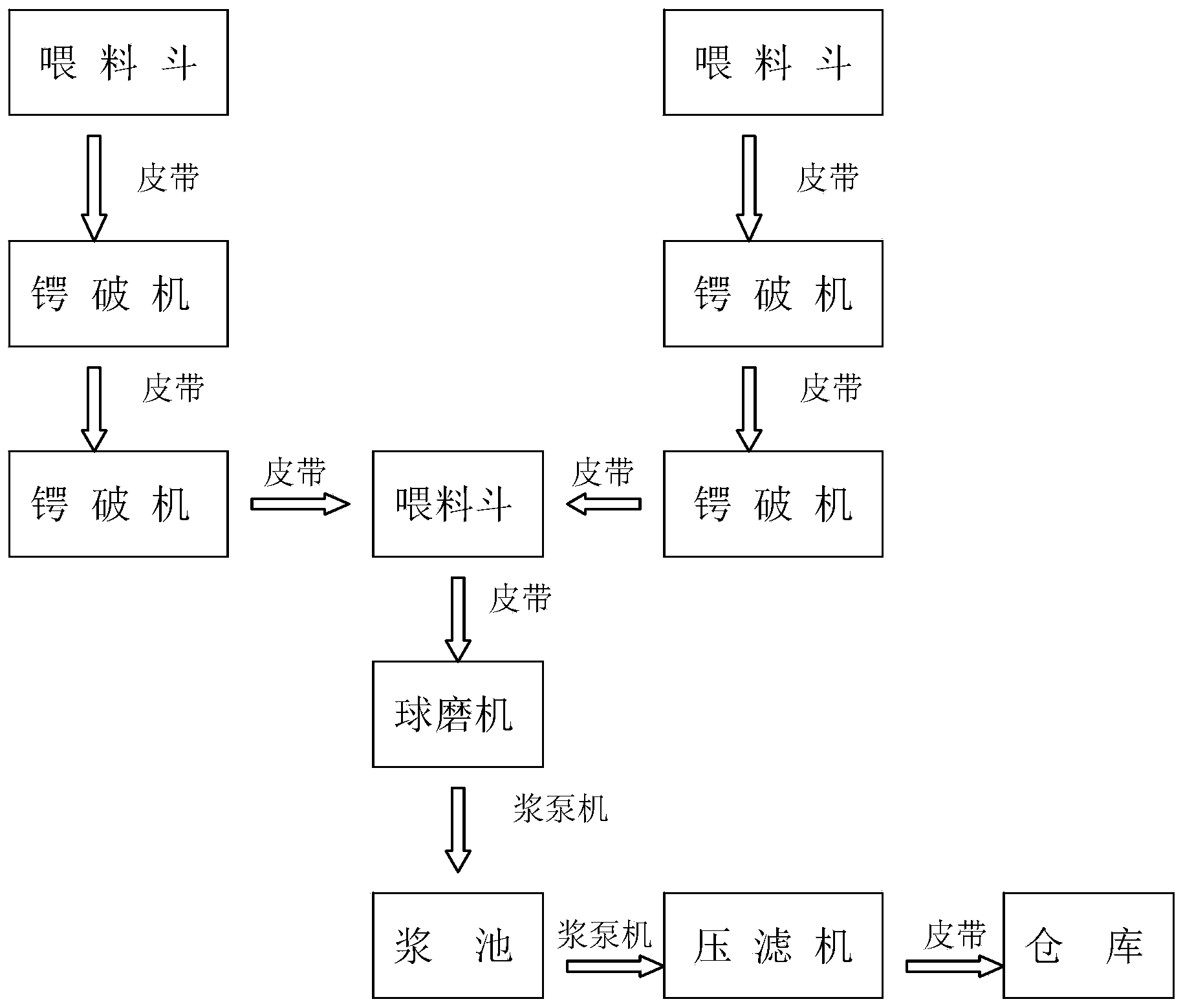

Image

Examples

Embodiment 1

[0033] Clay: 75 parts by weight,

[0034] Waste terracotta: 5 parts by weight,

[0035] Shale: 20 parts by weight.

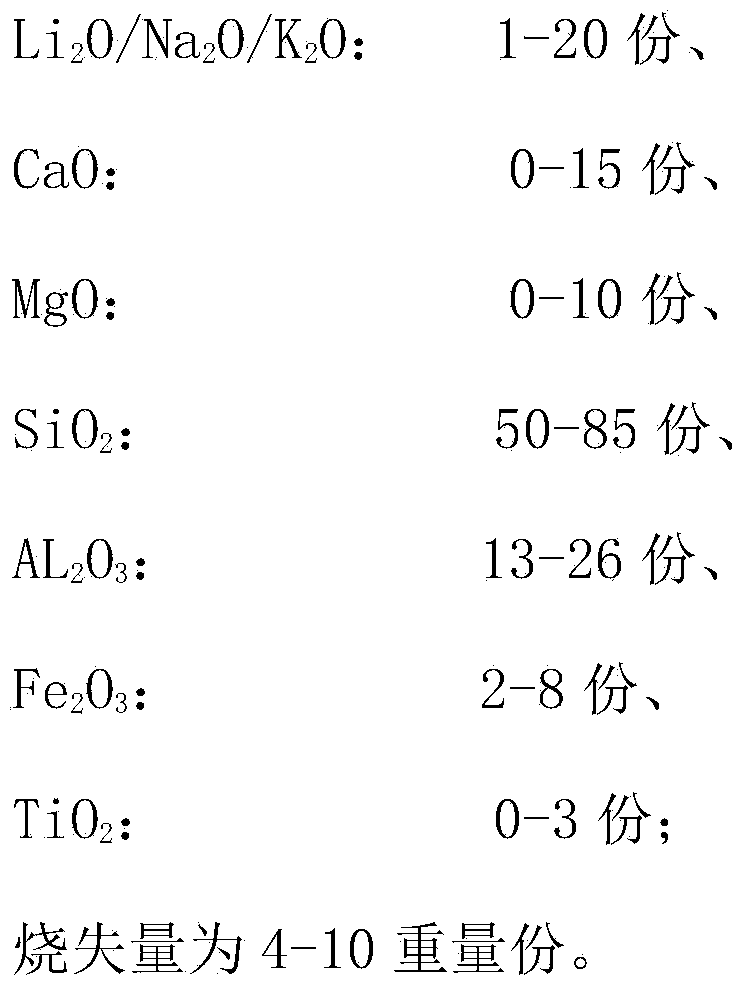

[0036] The chemical composition of the specific raw materials used is as follows:

[0037]

[0038]

[0039] Its specific production steps are as follows:

[0040] a. Store waste terracotta tiles and shale after crushing or weathering;

[0041] b. Mix waste terracotta tiles and shale into a ball mill in a ratio of 1:4, and add water to ball mill;

[0042] c. After the mud is fine enough, it is sieved and put into the slurry pool; the particle size of the particles in the sieved mud is 200um;

[0043] d. The slurry becomes a mud cake after pressure filtration, and the moisture content of the mud cake is 20%;

[0044] e. Mix the clay and the mud cake evenly in a ratio of 3:1.

[0045] In the process step a, the waste terracotta tiles and shale are crushed separately, the waste terracotta tiles are crushed by a jaw crusher, and the shale is crushed by a...

Embodiment 2

[0049] Clay: 50 parts by weight,

[0050] Waste terracotta: 10 parts by weight,

[0051] Shale: 40 parts by weight.

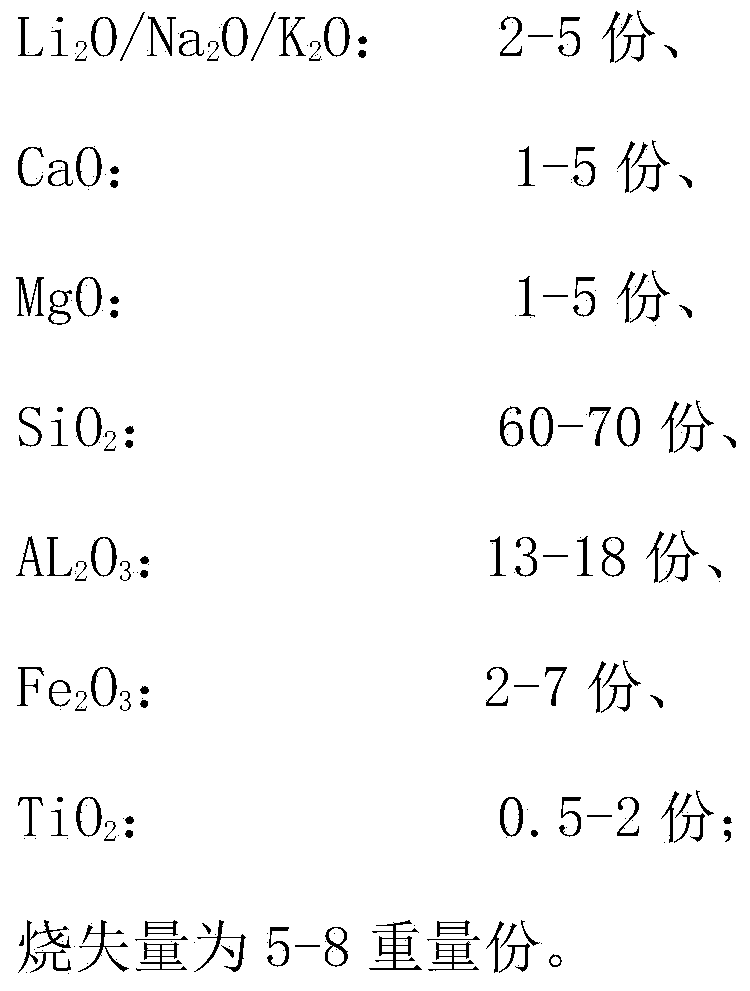

[0052] The chemical composition of the specific raw materials used is as follows:

[0053]

[0054]

[0055] Its specific production steps are as follows:

[0056] a. Store waste terracotta tiles and shale after crushing;

[0057] b. Mix waste terracotta tiles and shale into a ball mill in a ratio of 1:4, and add water to ball mill;

[0058] c. After the mud is fine enough, it is sieved and put into the slurry pool; the particle size of the particles in the sieved mud is 100um.

[0059] d. The slurry becomes a mud cake after pressure filtration, and the moisture content of the mud cake is 18%;

[0060] e. Mix the clay and the mud cake evenly in a ratio of 1:1.

[0061] In the process step a, the waste terracotta tiles and shale are crushed separately, the waste terracotta tiles are crushed by a jaw crusher, and the shale is crushed by a flange crush...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com