Production method of backing plate for roller kiln

A production method and technology of a roller kiln, which is applied in the field of backing plates for a roller kiln, can solve the problems of long firing cycle, high firing temperature, and high energy consumption, and achieve shortened firing cycle, short firing cycle, The effect of low firing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

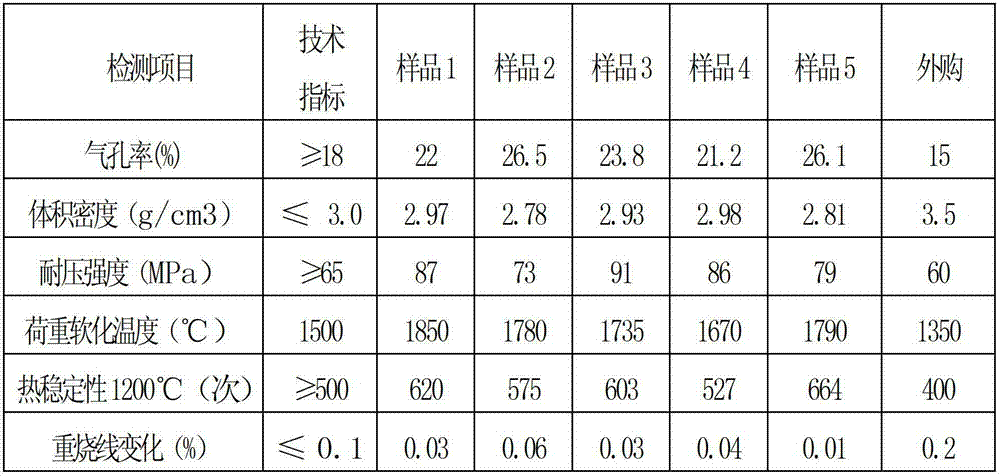

Examples

Embodiment 1

[0029] Process formula:

[0030] 20 parts of waste pad powder, 45 parts of alumina powder, 15 parts of calcined talc, 20 parts of clay, 0.4 parts of sodium tripolyphosphate, 0.5 parts of sodium carboxymethyl cellulose, 50 parts of water, ball milled into mud, 250 mesh or more ≤ 1 % fineness, mud moisture 33%-35%; then spray dry to 10% moisture content; become A material for later use;

[0031] 75 parts of waste backing plates below 8 mesh, 25 parts of raw bauxite below 8 mesh, and 10 parts of water are uniformly mixed into material A; that is to say, both materials have reached the fineness of passing through a 8 mesh sieve, the same below.

[0032] Use a one-time molding machine to press and shape, the equipment is set at a pressure of 20MPa, and then dried in a drying kiln until the moisture content is less than 1%;

[0033] The highest firing temperature was set at 1230°C, and the firing cycle was 45 minutes to obtain finished product 1.

Embodiment 2

[0035] 25 parts of waste backing powder, 35 parts of alumina powder, 12 parts of calcined talc, 25 parts of clay, 0.3 parts of sodium tripolyphosphate, 0.5 parts of sodium carboxymethyl cellulose, 50 parts of water, ball milled into mud, more than 250 mesh ≤ 1 % fineness, mud moisture 33%-35%; then spray dry to 11% moisture content; become A material for later use;

[0036] Mix 80 parts of waste pads below 8 mesh, 20 parts of raw bauxite below 8 mesh, and 10 parts of water into material A;

[0037] Use a one-time molding machine to press and shape, and the equipment is set at a pressure of 23MPa; then dry it with a drying kiln until the moisture content is less than 1%;

[0038] Use the roller kiln and other exterior wall brick products adapted to the design parameters to be co-fired in the roller backing kiln without changing the firing system of the existing products. The maximum temperature is set at 1200 ° C, and the firing cycle is 40 minutes. Finished product 2 . The f...

Embodiment 3

[0040] Process formula:

[0041] 22 parts of waste pad powder, 30 parts of alumina powder, 8 parts of calcined talc, 15 parts of clay, 0.4 part of sodium tripolyphosphate, 0.2 part of sodium carboxymethyl cellulose, 45 parts of water, ball milled into mud, more than 250 mesh ≤ 1 % fineness, mud moisture 33%-35%; then spray dry to 9% moisture content; become A material for later use;

[0042] Mix 80 parts of waste pads below 8 mesh, 20 parts of raw bauxite below 8 mesh, and 10 parts of water into material A;

[0043] Use a one-time molding machine to press and shape, and set the pressure of the equipment to 20MPa; then dry it with a drying kiln until the moisture content is less than 1%;

[0044] The highest firing temperature was set at 1200°C, and the firing cycle was 40 minutes to obtain finished product 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com