Red mud fine ceramic winebottle blank, and preparation process for manufacturing winebottle from same

A preparation process and technology for wine preforms, applied in the field of wine bottle blanks, can solve the problems of long firing cycle, high cost and low output, and achieve the effects of short firing cycle, low cost and large output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

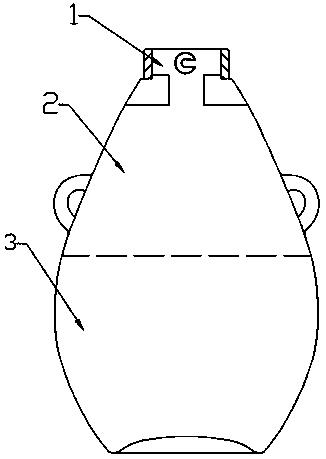

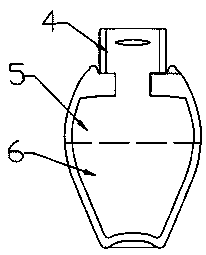

Image

Examples

Embodiment

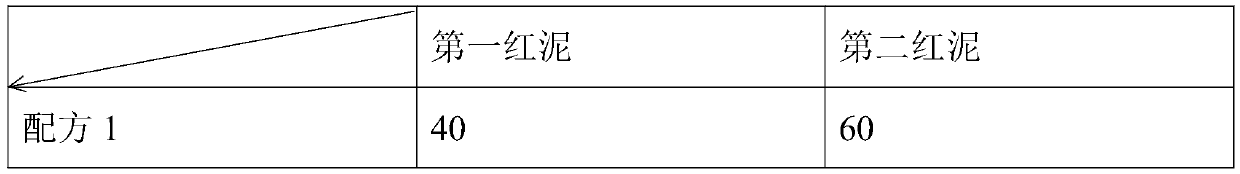

[0029] The red mud fine porcelain wine bottle blank provided in this embodiment and the preparation process of using the blank to make a wine bottle, specifically, the blank is composed of the first red mud and the second red mud. Wherein, see Table 1 for the weight percentages of the first red mud and the second red mud in the above blank material.

[0030]

[0031]

[0032] Table 1

[0033] See Table 2 for the components and their weight percentages in the above red mud.

[0034]

[0035] Table 2

[0036] IL in the first red mud and the second red mud is the loss on ignition of kaolin.

[0037] The preparation process of the red mud fine porcelain ceramic wine bottle includes the following steps: S1, batching according to the weight percentage of the above-mentioned blanks, and uniformly mixing the raw materials; S2, putting the mixed raw materials in S1 into a ball mill for ball milling, and then ball milling. Ball refining is put into the pool and mixed with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com