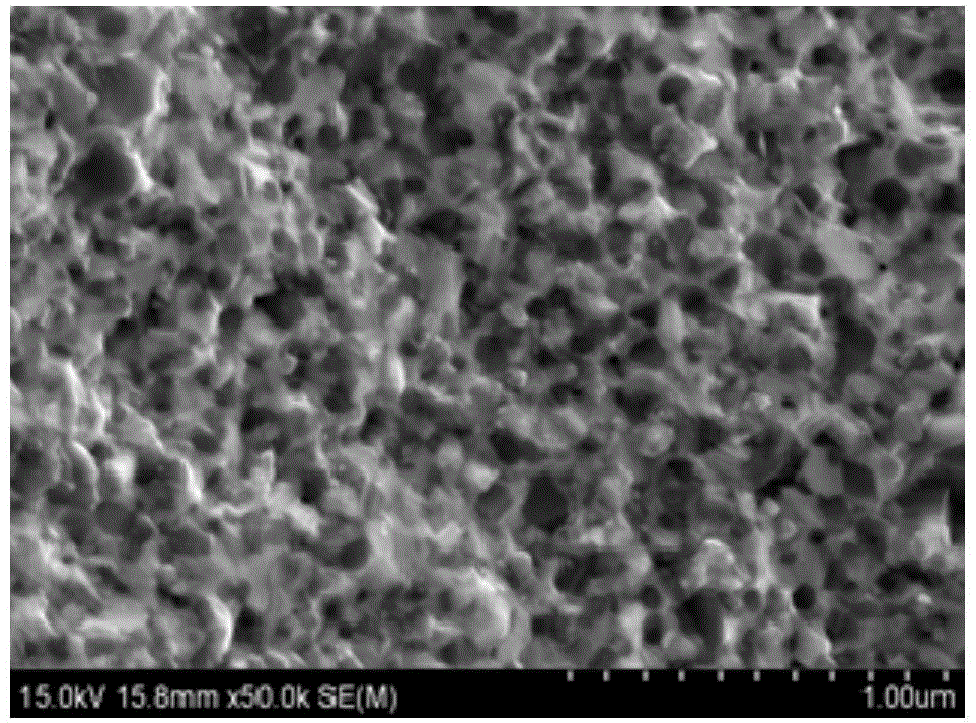

Method for preparing MgO-Y2O3 nanoceramics by two-step microwave sintering

A nano-ceramic, mgo-y2o3 technology is applied in the field of microwave two-step sintering to prepare MgO-Y2O3 nano-ceramic, which can solve the problems of high cost and carbon pollution of nano-ceramic, and achieve short firing cycle, uniform size and fine grain size. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Preparation of MgO-Y by a microwave two-step sintering 2 o 3 The method of nano ceramics, the steps are as follows:

[0028] (1) Weigh 42 parts by weight of MgO powder, 58 parts by weight of Y 2 o 3 powder mix;

[0029] (2) Put the powder prepared in step (1) into a polyurethane ball mill tank, then add 700 parts by weight of deionized water and 600 parts by weight of zirconia balls, and mill on a planetary ball mill for 6 hours to obtain MgO-Y 2 o 3 Slurry: Gained slurry is dried, and the PVA solution that accounts for 1wt% of dried slurry, concentration is 5wt% is added, granulated, and granulate passes 60 mesh sieves;

[0030] (3) Press the compact under 30MPa, and then isostatically press under 200MPa;

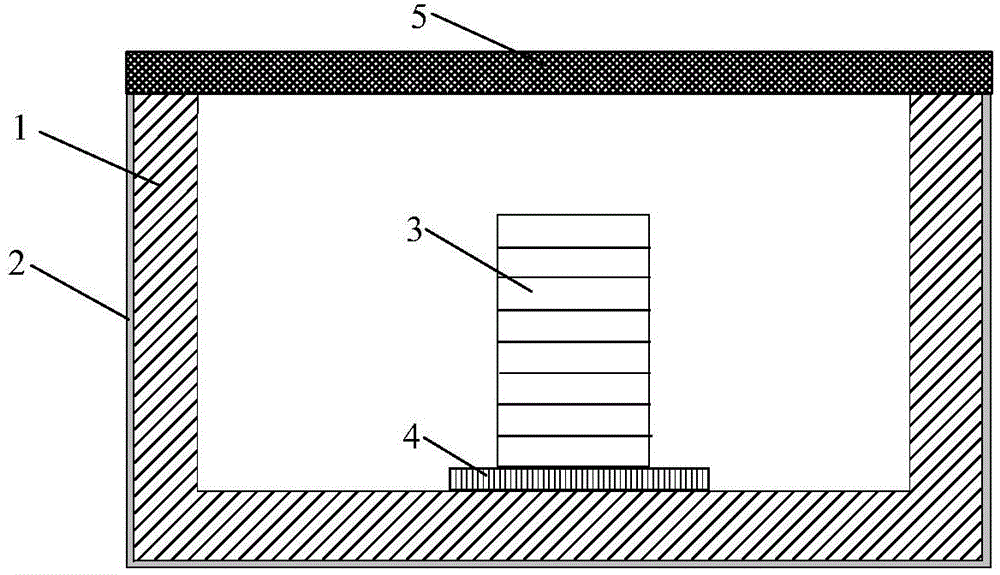

[0031] (4) Put the compact into an alumina sagger, coat the outer surface of the sagger with a layer of graphite paint, and then place the alumina sagger in a microwave oven;

[0032] (5) Adjust and control the output power of the microwave oven, raise the te...

Embodiment 2

[0034] Preparation of MgO-Y by a microwave two-step sintering 2 o 3 The method of nano ceramics, the steps are as follows:

[0035] (1) Weigh 43 parts by weight of MgO powder, 57 parts by weight of Y 2 o 3 powder mix;

[0036] (2) Put the powder prepared in step (1) into a polyurethane ball mill tank, then add 700 parts by weight of deionized water and 600 parts by weight of zirconia balls, and mill on a planetary ball mill for 4 hours to obtain MgO-Y 2 o 3 Slurry: Gained slurry is dried, and adding 1wt% concentration is the PVA solution of 5wt%, granulates, and granulate crosses 40 mesh sieves;

[0037] (3) Press the compact at 20MPa, and then isostatically press at 220MPa;

[0038] (4) Put the compact into an alumina sagger, coat a layer of carbon black paint on the outer surface of the sagger, and then place the alumina sagger in a microwave oven;

[0039] (5) Adjust and control the output power of the microwave oven, raise the temperature to 1340°C at a heating rate...

Embodiment 3

[0041] Preparation of MgO-Y by a microwave two-step sintering 2 o 3The method of nano ceramics, the steps are as follows:

[0042] (1) Weigh 40 parts by weight of MgO powder, 60 parts by weight of Y 2 o 3 powder mix;

[0043] (2) Put the powder prepared in step (1) into a polyurethane ball mill tank, then add 700 parts by weight of deionized water and 600 parts by weight of zirconia balls, and mill on a planetary ball mill for 3 hours to obtain MgO-Y 2 o 3 Slurry: Gained slurry is dried, and adding 1wt% concentration is the PVA solution of 5wt%, granulates, and granule crosses 100 mesh sieves;

[0044] (3) The green compact was pressed under 40MPa, and then isostatically pressed under 180MPa;

[0045] (4) Put the compact into an alumina sagger, coat a layer of green silicon carbide coating on the outer surface of the sagger, and then place the alumina sagger in a microwave oven;

[0046] (5) Adjust and control the output power of the microwave oven, raise the temperatur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com