Andesite tailing-based foamed ceramic

A technology of foam ceramics and andesite, which is applied in interdisciplinary fields, can solve the problems of many additives, unfavorable promotion, and increased production costs, and achieve the effects of reducing dissolution, avoiding secondary pollution, and low water absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

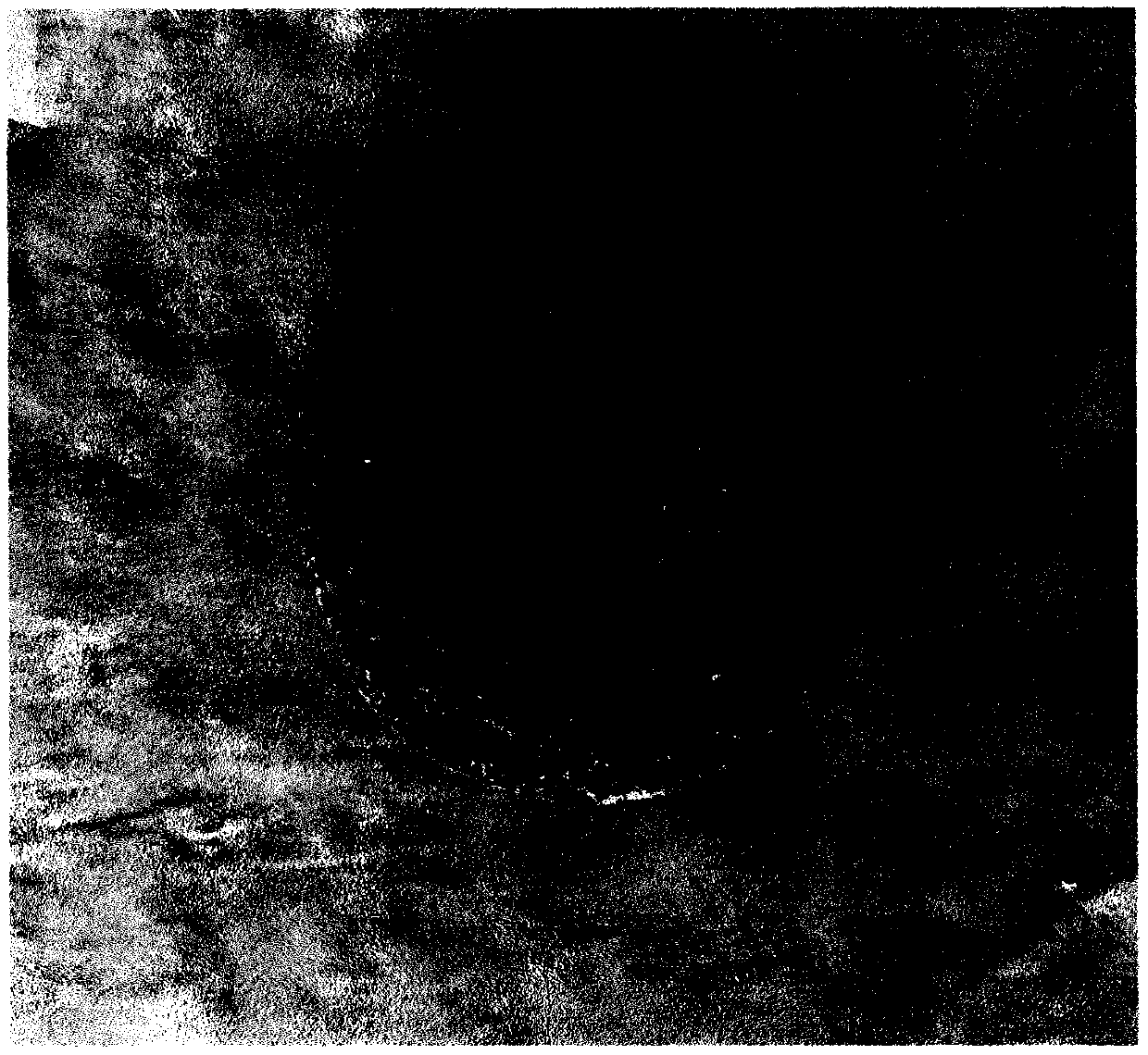

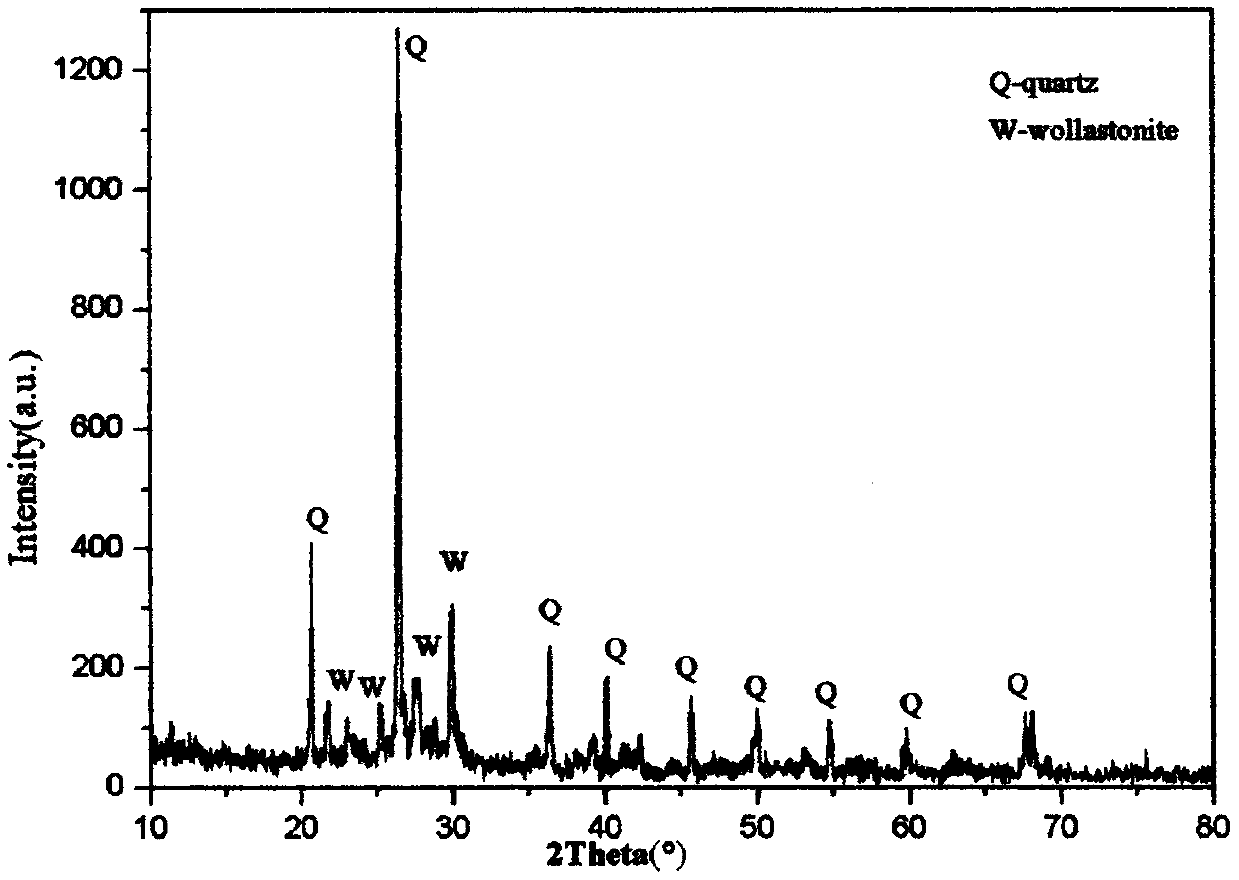

[0023] A lightweight ceramic foam material with andesite tailings slime and fly ash as main raw materials and its preparation method. The main composition of the foam ceramics is: 90% of andesite tailings slime, 8% of fly ash, and 2% of silicon carbide foaming agent .

[0024] Put the andesite tailings mud, fly ash and foaming agent into the ball mill for 8 hours. The ball-milled andesite tailings mud, fly ash and additives are respectively passed through a 200-mesh sieve. Accurately weigh andesite tailings sludge, fly ash, and foaming agent raw materials according to the formula, and stir and mix evenly. Add water with 2% mass of the material to the ingredients and stir evenly, put the prepared batch into a mold and press it into a block green body, and the molding pressure is 20MPa. Put the shaped green body into an oven and fully dry it at a temperature of 80°C. The dried green body is sintered in a muffle furnace from room temperature to 1200°C at a heating rate of 3°C / m...

Embodiment 2

[0026] A lightweight ceramic foam material with andesite tailings slime and fly ash as main raw materials and its preparation method. The main components of the foam ceramics are: 70% andesite tailings slime, 25% fly ash, and 5% foaming agent silicon carbide .

[0027] Put the andesite tailings mud, fly ash and foaming agent into the ball mill for 8 hours. The ball-milled andesite tailings mud, fly ash and additives are respectively passed through a 200-mesh sieve. Accurately weigh andesite tailings sludge, fly ash, and foaming agent raw materials according to the formula, and stir and mix evenly. Add water with 3% mass of the material to the ingredients and stir evenly, put the prepared batch into a mold and press it into a block green body, and the molding pressure is 15MPa. Put the shaped green body into an oven and fully dry it at a temperature of 90°C. The dried green body is sintered in a muffle furnace from room temperature to 1150°C at a heating rate of 4°C / min. The...

Embodiment 3

[0029] A lightweight ceramic foam material with andesite tailings slime and fly ash as main raw materials and its preparation method. The main components of the foam ceramics are: 50% of andesite tailings slime, 48% of fly ash, and 2% of silicon carbide foaming agent .

[0030] Put the andesite tailings mud, fly ash and foaming agent into the ball mill for 8 hours. The ball-milled andesite tailings mud, fly ash and additives are respectively passed through a 200-mesh sieve. Accurately weigh andesite tailings sludge, fly ash, and foaming agent raw materials according to the formula, and stir and mix evenly. Add water with 4% mass of the material to the ingredients and stir evenly, put the prepared batch into a mold and press it into a block green body, and the molding pressure is 10MPa. Put the shaped green body into an oven and fully dry it at a temperature of 100°C. The dried green body is sintered in a muffle furnace from room temperature to 1110°C at a heating rate of 5°C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com