Bamboo charcoal fiber and preparation method thereof and application of bamboo charcoal fiber to cigarette filter tips

A technology of bamboo charcoal fiber and cigarette filter tip, applied to the application of bamboo charcoal fiber in cigarette filter tip, in the field of bamboo charcoal fiber, can solve the problems of increasing the difficulty of filter tip processing, peculiar smell of smoke, and small reduction, and achieve product quality The effect of poor stability, low density of bamboo charcoal and strong adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Material selection: choose 6 to 8 year old bamboo slices near the root and put them into the bamboo charcoal kiln.

[0042] Carbonization: 4 steps are taken: (1) drying at 100°C for 4 hours; (2) pre-carbonization at 250°C for 4 hours; (3) carbonization at 400°C for 1.5 hours; (4) calcination at 850°C for 30 minute.

[0043] Processing: After the calcination, when the natural temperature of the bamboo charcoal kiln drops to 50°C, the bamboo charcoal comes out of the kiln; the bamboo charcoal blocks are crushed to an average particle size of 2 μm, and packed for later use.

[0044] Add 15% bamboo charcoal based on the weight of the cellulose acetate slices, heat the bamboo charcoal powder and the cellulose acetate slices at a temperature of 260°C and a pressure of 3MPa to blend, mix well and then make silk, the diameter of the tow is 10μm; the bamboo charcoal tow is processed Then make a filter.

Embodiment 2

[0046] Material selection: choose 6 to 8 year old bamboo slices near the root and put them into the bamboo charcoal kiln.

[0047] Carbonization: 4 steps are taken: (1) drying at 150°C for 3.5 hours; (2) pre-carbonization at 180°C for 5 hours; (3) carbonization at 450°C for 1 hour; (4) then drying at 1000°C Calcined for 20 minutes.

[0048] Processing: After the calcination, the bamboo charcoal is discharged from the kiln after the temperature of the bamboo charcoal kiln is lowered to below 50°C; the charcoal is crushed and processed to an average particle size of 3 μm, and packed for later use.

[0049] Based on the weight of acetate fiber slices, add 0.1% bamboo charcoal, heat and blend bamboo charcoal powder and propionate fiber slices at a temperature of 300°C and a pressure of 5 MPa, mix them and make silk, the diameter of which is 5 μm; bamboo charcoal tows are processed Then make a filter.

Embodiment 3

[0051] Material selection: choose 6 to 8 year old bamboo slices near the root and put them into the bamboo charcoal kiln.

[0052] Carbonization: 4 steps are taken: (1) drying at 120°C for 200 minutes; (2) pre-carbonization at 350°C for 5 hours; (3) carbonization at 350°C for 1.5 hours; (4) calcination at a temperature above 450°C for 40 minutes .

[0053] Processing: After the temperature of the bamboo charcoal kiln is lowered to below 50°C, the bamboo charcoal is discharged from the kiln; the charcoal block is crushed and processed to a particle size of 1 μm, and packed for later use.

[0054] Based on the weight of acetate fiber slices, add 8% bamboo charcoal, heat and blend bamboo charcoal powder and acetate fiber slices at a temperature of 250°C and a pressure of 6 MPa, and then make silk after mixing, with a diameter of 8 μm; the bamboo charcoal tow is processed and made into a filter.

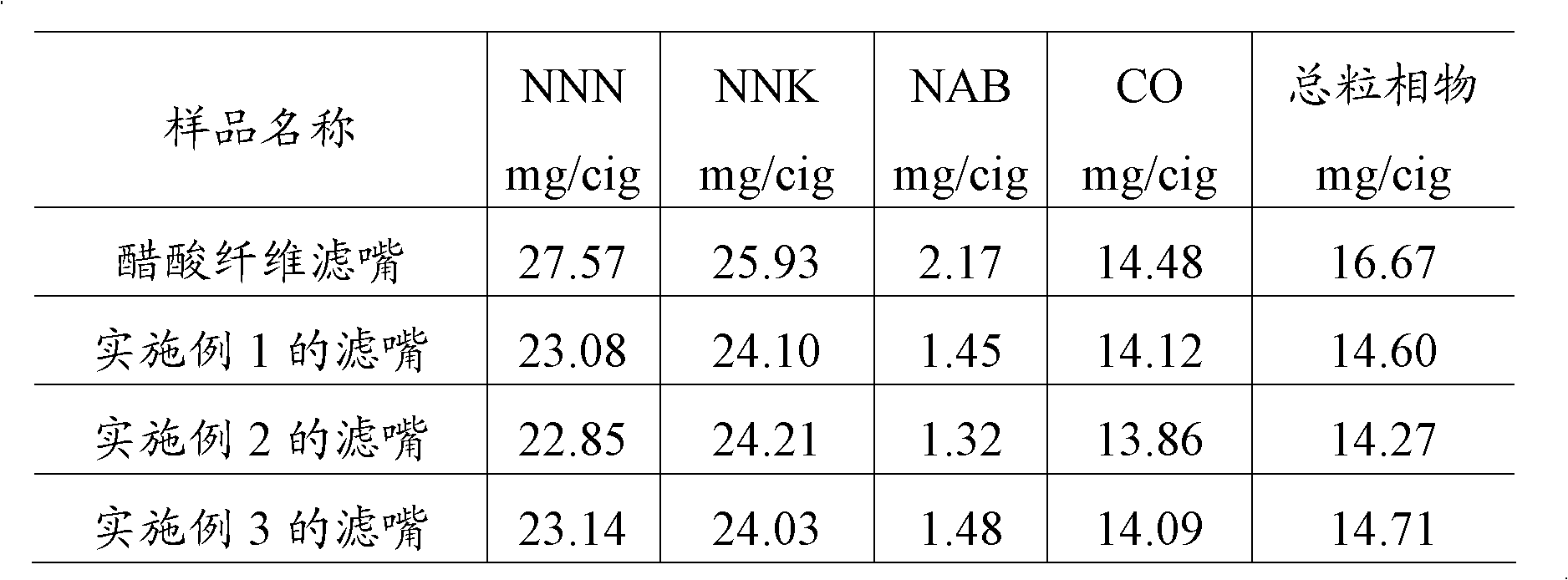

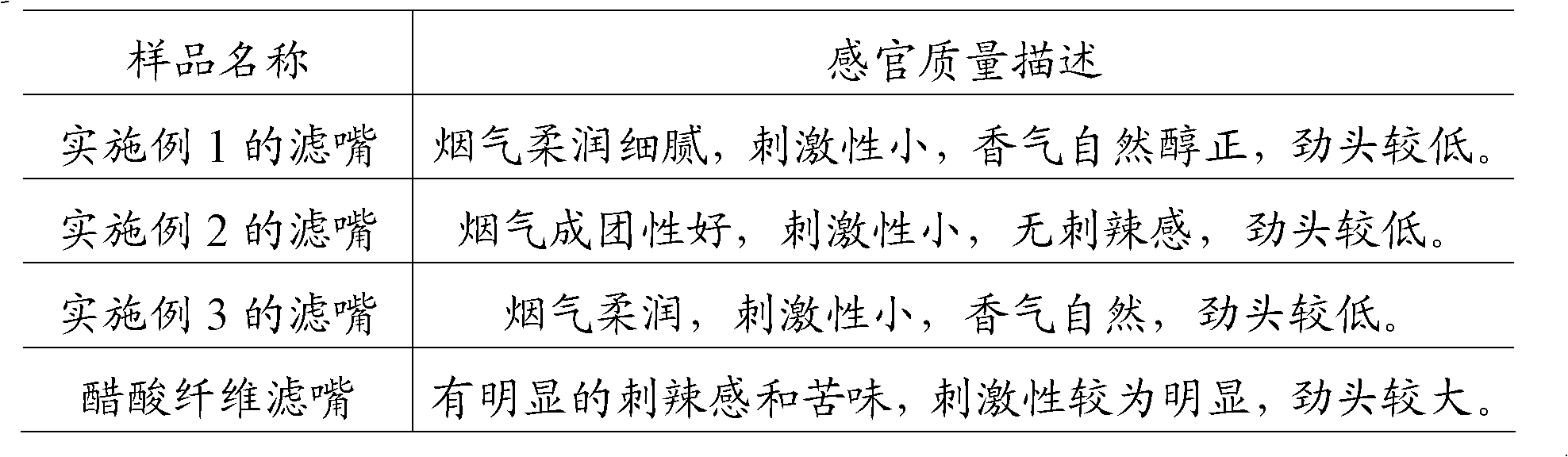

[0055] The filter tips obtained in the above examples were compared with those added...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com