Method for producing microcrystalline jade panel with iridescent entire body by utilization of roller kiln

A technology of microcrystalline jade and roller kiln, which is applied in the field of producing full-body illusion microcrystalline jade slabs by using roller kiln, which can solve the problems of monotonous crystal texture, fading out, and inability to replace natural stone, etc., and achieve the effect of short firing cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The steps of the method for producing the first full-body illusion microcrystalline jade plate by using a roller kiln are as follows:

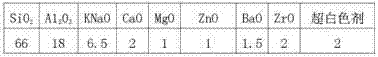

[0026] (1) Prepare a glass-ceramic frit produced by a conventional process, the chemical composition of which is (percentage by weight):

[0027]

[0028] Above-mentioned rare earth element selects praseodymium oxide for use;

[0029] The preparation method step of glass-ceramic frit is:

[0030] ①According to the above formula, mix various minerals evenly;

[0031] ② Melting in the melting furnace for 1 to 5 hours and completing the physical and chemical reactions to form glass-ceramic melt;

[0032] ③The glass-ceramic melt is water-quenched into small particles, and after being filtered dry, it is bagged for later use to obtain a green glass-ceramic frit;

[0033] (2) Preparation of color development aids:

[0034] ①According to the following formula, various mineral raw materials are batched (percentage by weight):

[0035] ...

Embodiment 2

[0041] The method steps for producing the second kind of full-body illusion microcrystalline jade plate by using a roller kiln are as follows:

[0042] (1) Prepare the glass-ceramic frit produced by the conventional process, its chemical composition is (percentage by weight):

[0043]

[0044] The frit preparation method is the same as in Example 1.

[0045] (2) Preparation of color development aids:

[0046] ①According to the following formula, various mineral raw materials are batched (percentage by weight):

[0047]

[0048] ②After wet ball milling, the fineness is 250 mesh sieve and the remaining O.2~1.2%;

[0049] ③ Stir in the stirring tank for at least 12 hours, and measure the viscosity with a Tuo's viscometer for 50-75 seconds;

[0050] (3) Making a kind of kiln furniture is the same as that in Embodiment 1.

[0051](4) Use an automatic distributing device to distribute the above-mentioned glass-ceramic frits on the refractory backing plate according to a p...

Embodiment 3

[0053] The steps of the method for producing the third kind of full-body illusion microcrystalline jade plate by using a roller kiln are as follows:

[0054] (1) Prepare two kinds of glass-ceramics frits produced by conventional processes, and their chemical components are respectively (weight percent):

[0055] 1# frit

[0056]

[0057] Above-mentioned rare earth element selects erbium oxide for use;

[0058] 2# frit

[0059]

[0060] The above two frit preparation methods are the same as in Example 1.

[0061] (2) Preparation of color development aids:

[0062] ①According to the following formula, various mineral raw materials are batched (percentage by weight):

[0063]

[0064] ②After wet ball milling, the fineness is 250 mesh sieve and the remaining O.2~1.2%;

[0065] ③ Stir in the stirring tank for at least 12 hours, and measure the viscosity with a Tuo's viscometer for 60-100 seconds;

[0066] (3) Making a kind of kiln furniture is the same as that in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com