Method for producing split-phase furnace transmutation decorative composite materials from red mud by roller kilns

A composite material and roller kiln technology, which is applied in the field of architectural ceramics production, can solve problems such as limitations in product application fields, lower production costs, and undiscovered issues, and achieve superior decorative effects, lower costs, and strong capabilities.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

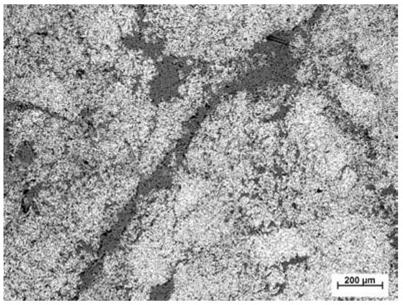

Embodiment 1

[0037] (1) Dosing according to mass percentage: 60% of red mud, 10% of feldspar, 10% of vanadium-titanium slag, 10% of quartz, 6% of borax, 2% of lepidolite and 2% of talc, put in the frit furnace, after 1450 After melting at ℃, water quenching, crushing and sieving, and the sieve residue is mixed according to the mass percentage, of which 8 mesh to 10 mesh account for 20%, 11 mesh to 15 mesh account for 60%, 15 mesh to 20 mesh account for 20% , which is the phase-separated kiln transformation raw material;

[0038] (2) Dosing according to mass percentage: 47% feldspar, 27% clay, 16% coke gemstone, 5% pyrophyllite and 5% manzu stone, put them in a ball mill with a water-to-material ratio of 40:100, after ball milling for 36 hours Spray granulation, put the granules in the mold, press 200MPa to get the green body;

[0039] (3) Distribute the phase-splitting kiln transformation raw material obtained through step (1) on the green body obtained through step (2) according to the c...

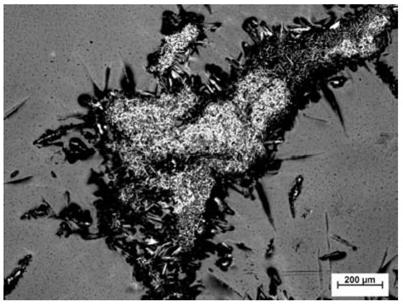

Embodiment 2

[0042] (1) Dosing according to mass percentage: red mud 50%, feldspar 7%, vanadium-titanium slag 20%, quartz 10%, borax 6%, lepidolite 5% and talc 2%, put in the frit furnace, through After melting at 1450°C, water quenching, crushing and sieving, the sieve residue is mixed according to the mass percentage, of which 8 mesh to 10 mesh account for 20%, 11 mesh to 15 mesh account for 60%, 15 mesh to 20 mesh account for 20% %, which is the phase-separated kiln transformation raw material;

[0043] (2) Dosing according to mass percentage: 47% feldspar, 27% clay, 16% coke gemstone, 5% pyrophyllite and 5% manzu stone, put them in a ball mill with a water-to-material ratio of 40:100, after ball milling for 36 hours Spray granulation, put the granules in the mold, press 200MPa to get the green body;

[0044] (3) Distribute the phase-splitting kiln transformation raw material obtained through step (1) on the green body obtained through step (2) according to the cloth amount of 4.7 kg / s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Flexural strength | aaaaa | aaaaa |

| Flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com