Method and device for producing drinking water through deep purifying by DMI and activated carbon composite bed

A deep purification and composite bed technology, applied in chemical instruments and methods, oxidized water/sewage treatment, water pollutants, etc., can solve problems such as insufficient utilization of water resources, unqualified water output during the cultivation period, and high equipment maintenance costs , to achieve the effect of low overall operating cost, fast filtering speed and reduced infrastructure cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

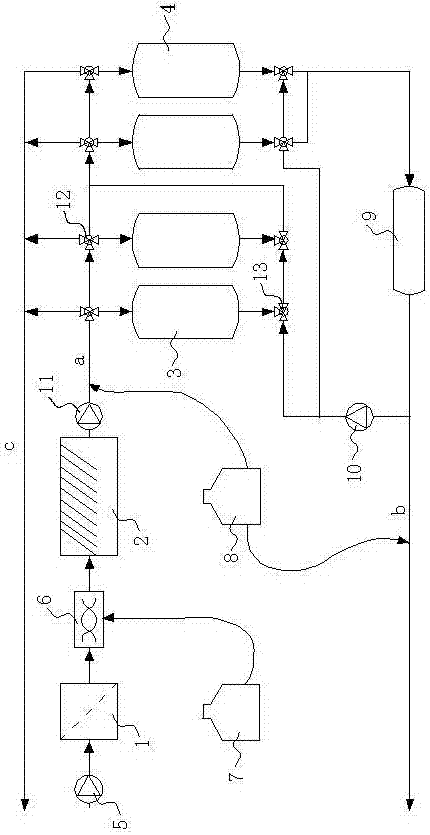

[0036] The method for deep purification of DMI and active carbon composite bed to produce drinking water of the present invention, when processing raw water is underground water, realizes by following steps:

[0037] a. Sterilization and antivirus: add oxidant to raw water;

[0038] b. Arsenic removal: Add soluble iron-based compounds to the water, and the amount of addition depends on the amount of arsenic in the water;

[0039] c. Removal of heavy metals: In the raw water where oxidants exist, through the adsorption and separation of mineral adsorbent DMI, the heavy metals in the water are adsorbed and removed in the form of hydroxide particles. The removal rate of heavy metals is over 99.8%. Hardness above 30%;

[0040] d. Activated carbon adsorption and refining: use activated carbon to absorb and remove residual organic matter, bacteria, viruses, residual heavy metals and free chlorine in the water, so as to obtain fully compliant, pure, healthy and palatable drinking wa...

Embodiment 2

[0043] The method for deep purification of DMI and active carbon composite bed to produce drinking water of the present invention, when the raw water is treated as surface water, is realized through the following steps:

[0044] a. Removal of mechanical impurities: filter the raw water with a grid filter to remove mechanical impurities;

[0045] b. Flocculation and turbidity reduction: add flocculant and stir rapidly to form insoluble substances from impurities in the water, carry out precipitation and separation, and reduce water turbidity.

[0046] c. Sterilization and antivirus: add oxidant to raw water;

[0047] d. Arsenic removal: add soluble iron-based compounds, such as ferrous sulfate, to the water, and the amount of addition depends on the amount of arsenic in the water;

[0048] e. Removal of heavy metals: In the raw water where oxidants exist, through the adsorption and separation of mineral adsorbent DMI, the heavy metals in the water are adsorbed and removed in t...

Embodiment 3

[0052] DMI of the present invention and the method for deep purification of activated carbon composite bed to produce drinking water specifically comprise the following steps:

[0053] 1. Use the grid to intercept the large solid suspended solids in the water, such as weed leaves, plastic bags and other objects; then pump the water into the sedimentation tank, quickly stir and settle through the flocculant, and assist oxygen aeration and other means to remove the organic matter in the water Precipitation to achieve preliminary purification of water; groundwater does not need this process because it is relatively clear;

[0054] 2. For underground water sources, most of the existing waterworks in my country need the process of flocculation and sedimentation, because the organic matter in groundwater must be removed through this process, and the quartz sand or manganese sand filter at the back end cannot remove organic matter, and the present invention does not need this process ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com