Novel process for industrial mass production of foamed ceramic, foamed ceramic, application of foamed ceramic and building component

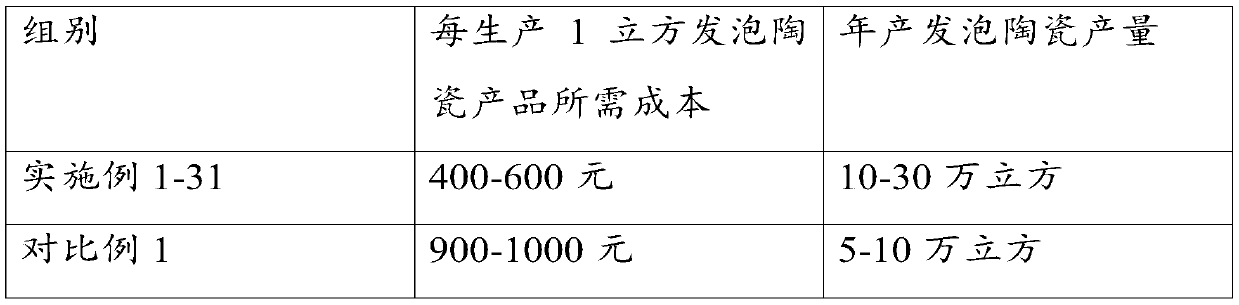

A technology of foamed ceramics and a new process, which is applied in the field of foamed ceramics, can solve the problems of low output, restricted the popularization and application of foamed ceramics, and high cost of foamed ceramics, and achieves increased output, low energy costs and equipment costs, and improved sintering. short cycle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

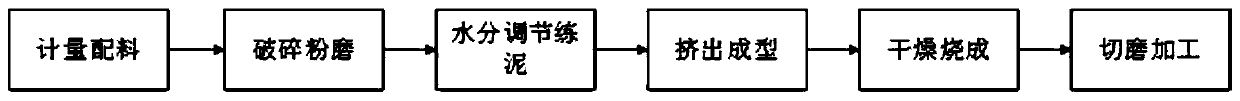

[0142] A new process for industrial mass production of foamed ceramics, comprising the following steps: the crushed (broken and ground) raw materials are sequentially smelted, extruded, dried and fired to obtain the foamed ceramics;

[0143] Raw materials include: 59% of the main raw material, 35% of the plastic regulator and 6% of the admixture; the main raw material is mineral processing tailings, the plastic regulator is 25% of kaolin and 10% of cellulose, and the admixture includes 3% of the foaming agent and the regulator 3%;

[0144] Note: The above percentages refer to the percentage of the raw material in the total mass of raw materials;

[0145] Foamed ceramics include the following components in mass percentage: K 2 O and Na 2 O total 18%, Al 2 o 3 35%, SiO 2 45%, CaO and MgO total 8% and Fe 2 o 3 4%;

[0146] The plasticity index of the mud obtained after mud refining is 6, the molding pressure is 17MPa, the vacuum degree during molding is 0.05MPa, and the ...

Embodiment 2-3

[0150] A new process for industrial mass production of foamed ceramics. The difference from Example 1 is that the main raw materials in Examples 2-3 are coal gangue and fly ash respectively.

Embodiment 4-5

[0152] A new process for industrial mass production of foamed ceramics. The difference from Example 1 is that the plastic regulators in Examples 4-5 are bentonite and polyacrylamide respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com