Sintered brick prepared from waste paper papermaking sludge and preparation method thereof

A technology for making paper and sintering bricks from waste paper, which is applied in the fields of sludge treatment, chemical instruments and methods, water/sludge/sewage treatment, etc. The method is simple, reducing the growth of bacteria, and the effect of good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

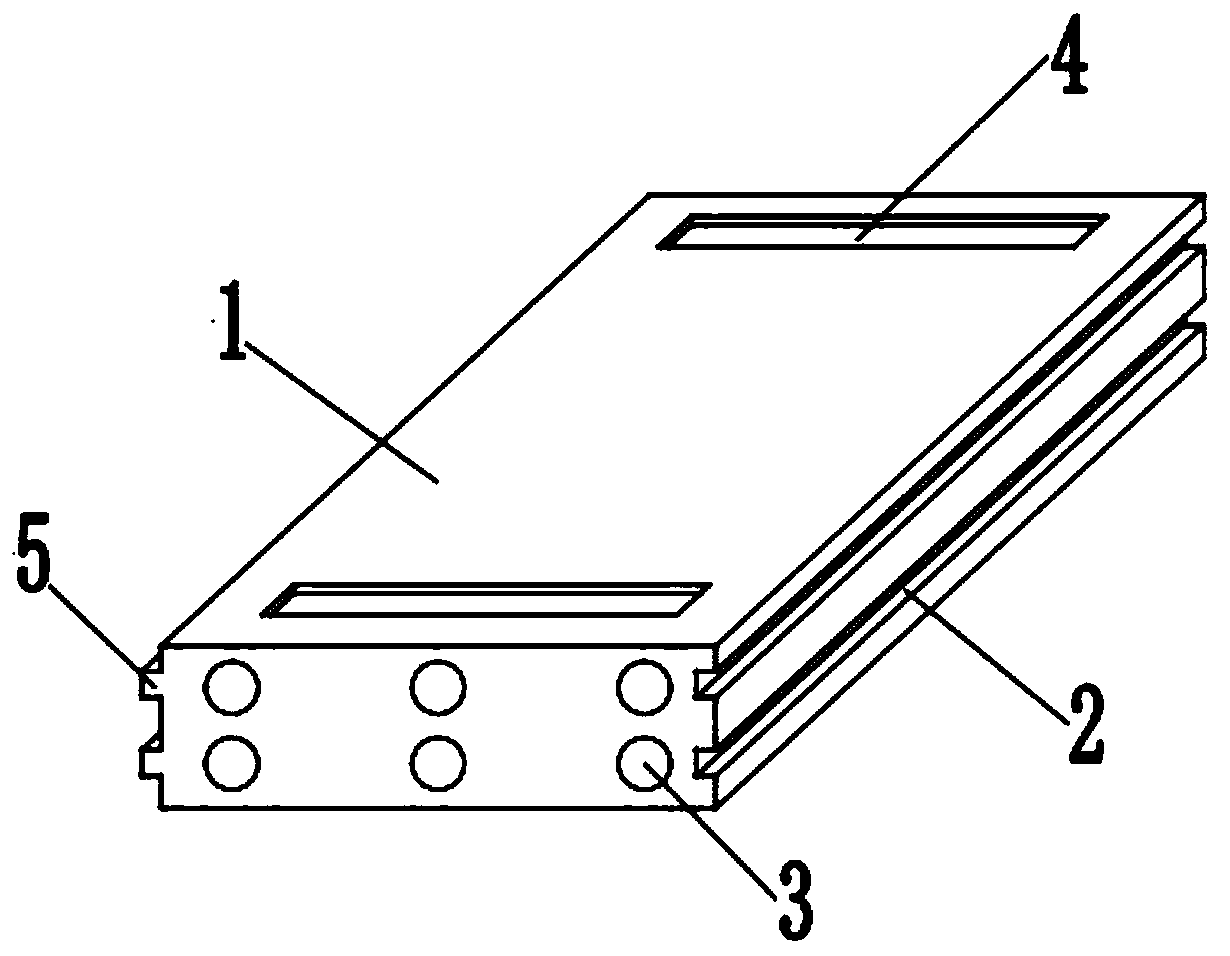

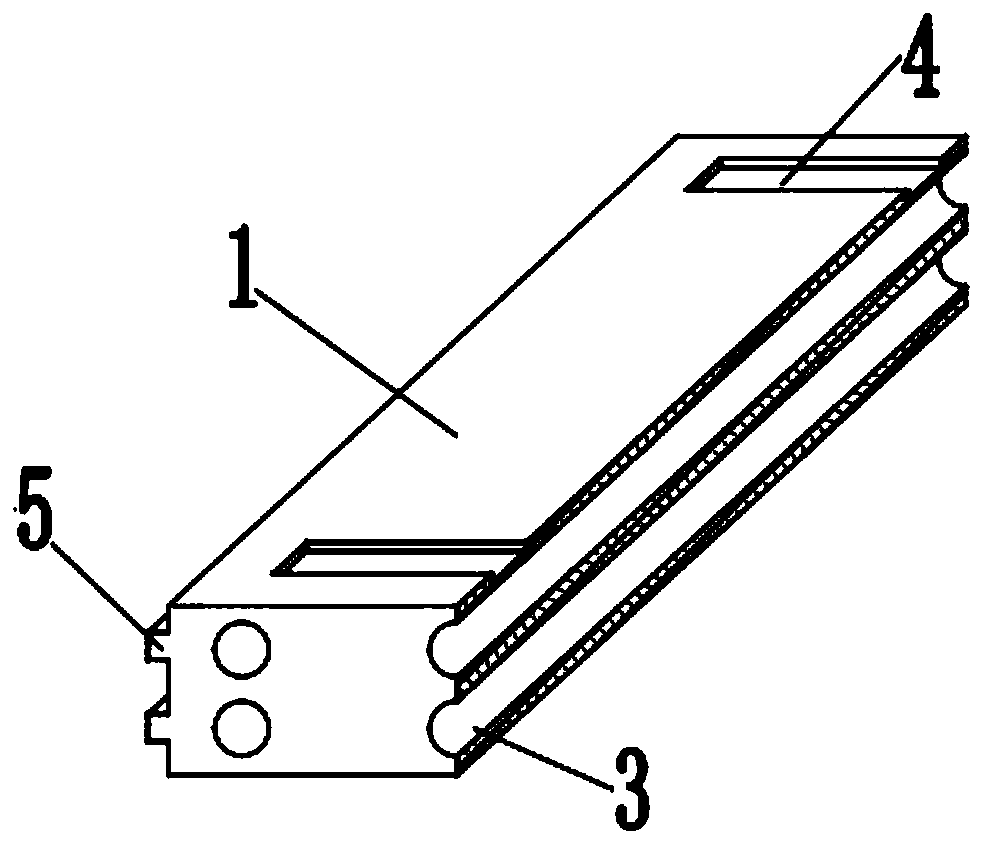

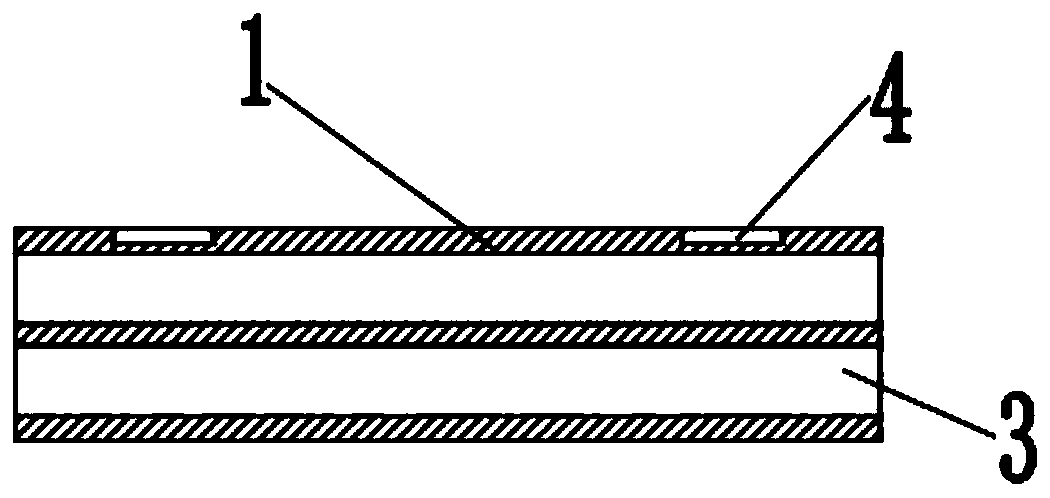

[0033] see Figure 1-3 , the present invention hereby provides a sintered brick made of waste paper papermaking sludge, which includes a sintered brick body 1, a plurality of communication holes 3 are opened inside the sintered brick body 1, and two holes 3 are opened on the outer wall of the sintered brick body 1 side. In the groove 2, two protrusions 5 are provided on the outer wall of the fired brick body 1 away from the groove 2, and limiting grooves 4 are provided on both sides of the top of the fired brick body 1.

[0034] see Figure 4 , utilize waste paper papermaking sludge to make the preparation method of sintered brick, comprise the following steps:

[0035] S1, raw material pretreatment: prepare waste paper papermaking sludge, put it into a mixer, and rotate it at a speed of 30 rpm for 6 minutes. While stirring, observe the impurities and waste materials in the papermaking sludge and take them out. Put the papermaking sludge into the holding equipment;

[0036]...

Embodiment 2

[0044] see Figure 1-3 , the present invention hereby provides a sintered brick made of waste paper papermaking sludge, which includes a sintered brick body 1, a plurality of communication holes 3 are opened inside the sintered brick body 1, and two holes 3 are opened on the outer wall of the sintered brick body 1 side. In the groove 2, two protrusions 5 are provided on the outer wall of the fired brick body 1 away from the groove 2, and limiting grooves 4 are provided on both sides of the top of the fired brick body 1.

[0045] see Figure 4 , utilize waste paper papermaking sludge to make the preparation method of sintered brick, comprise the following steps:

[0046] S1, raw material pretreatment: prepare waste paper papermaking sludge, put it into a mixer, and rotate it at a speed of 45 rpm for 7 minutes. While stirring, observe the impurities and waste materials in the papermaking sludge and take them out. Put the papermaking sludge into the holding equipment;

[0047]...

Embodiment 3

[0055] see Figure 1-3 , the present invention hereby provides a sintered brick made of waste paper papermaking sludge, which includes a sintered brick body 1, a plurality of communication holes 3 are opened inside the sintered brick body 1, and two holes 3 are opened on the outer wall of the sintered brick body 1 side. In the groove 2, two protrusions 5 are provided on the outer wall of the fired brick body 1 away from the groove 2, and limiting grooves 4 are provided on both sides of the top of the fired brick body 1.

[0056] see Figure 4 , utilize waste paper papermaking sludge to make the preparation method of sintered brick, comprise the following steps:

[0057] S1, raw material pretreatment: prepare waste paper papermaking sludge, put it into a mixer, and rotate it at a speed of 60 rpm for 8 minutes. While stirring, observe the impurities and waste materials that appear in the papermaking sludge and take them out. Put the papermaking sludge into the holding equipmen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com