Method for preparing foamed ceramic plate by taking pulverized fuel ash as raw material via microwave sintering

A foamed ceramic plate and microwave sintering technology, which is applied to ceramic products, other household utensils, household utensils, etc., can solve the problems of long sintering period, high sintering temperature, and uneven sintering, so as to save ceramic raw materials and sinter Short cycle, satisfying the effect of heat preservation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] The preparation method of foamed ceramic plate of the present invention comprises the steps:

[0022] (1) The above-mentioned ceramic raw materials are put into balls according to the formula ingredients and mixed evenly by wet ball milling. The ball milling medium can be medium aluminum ceramic balls or corundum ceramic balls. The ball milling speed can be 11-14 rpm, and the ball milling time can be 8-15 hours. ;

[0023] (2) Spray-drying to make powder, after stale for 24 hours, enter the mold and lay flat to make powder green body;

[0024] (3) The powder green body is directly microwave-heated to 1080-1150°C for microwave sintering, or preheated to 300-800°C, and then microwave-heated to 1080-1150°C for microwave sintering to form a lightweight foam with uniform distribution of closed pores ceramic plate;

[0025] (4) After cold processing such as cutting, the finished product of the required specification is made.

[0026] fly ash

[0027] The main source of th...

Embodiment 1

[0044] Foamed ceramic board formula (percentage by weight): fly ash 70%, low-temperature waste frit 10%, waste glass 4.5%, talc 8%, clay 7%, 2000 mesh silicon carbide micropowder 0.3%, debonding agent 0.2%;

[0045] The preparation method comprises the following steps:

[0046] (1) above-mentioned raw material carries out wet ball milling, and ball milling medium is corundum ceramic ball, and ball milling speed is 13 revs / min, and ball milling time is 9. hours;

[0047] (2) The slurry obtained by ball milling is made into powder by spray drying (the particle size is 20-80 mesh), and it is placed into a mold after being stale for 24 hours;

[0048] (3) Microwave heating to 1080-1150°C for sintering (microwave power: 30kW), firing cycle: 120min, high temperature zone holding time: 10min;

[0049] (4) Finished products of required specifications are made by cold processing such as cutting;

[0050] The foamed ceramic plate prepared in this embodiment has a bulk density of 0.28g...

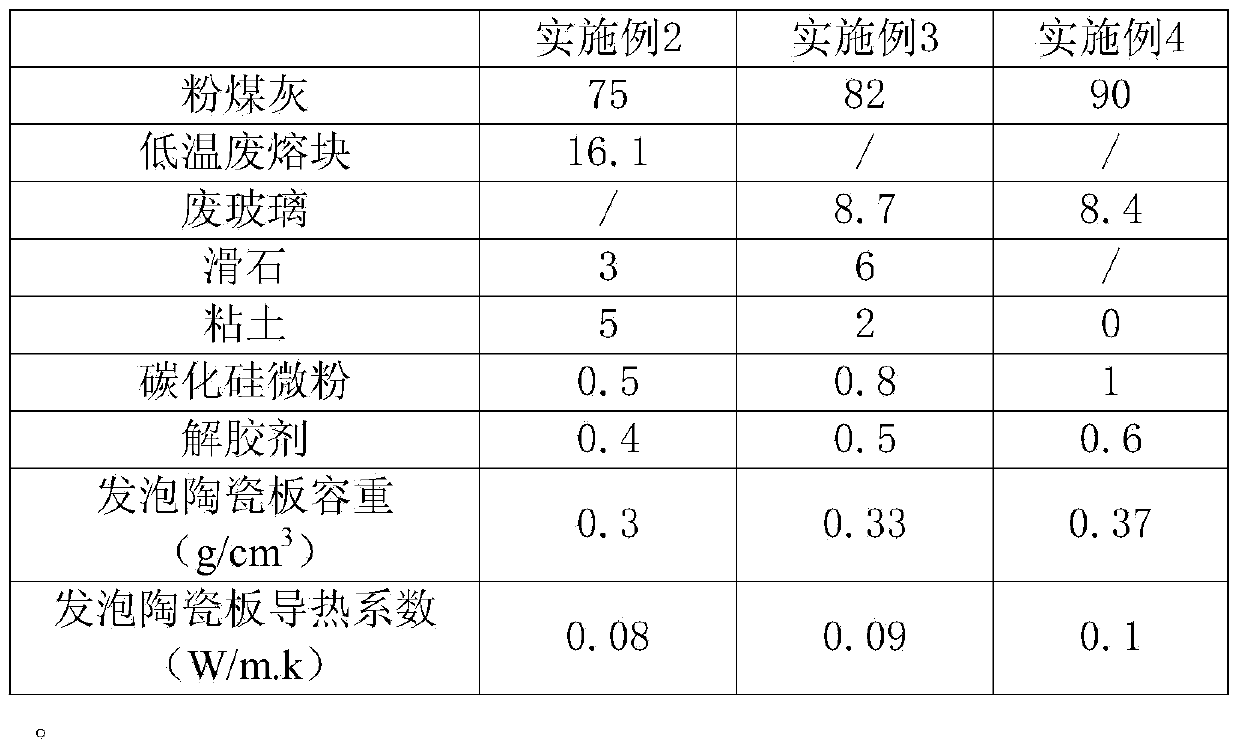

Embodiment 2~4

[0052] The preparation method of embodiment 2~4 is the same as embodiment 1, but the formula (weight percentage) used in each embodiment sees the following table 1:

[0053] Table 1

[0054]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com