Energy-saving novel ceramic slurry granulation process and equipment for same

A technology of ceramic slurry and ceramic raw materials, which is applied in the direction of liquid separation into beads and granulation, which can solve the problems of easy deformation and cracking of bricks, increase of sintering time, and long molding time, so as to ensure energy recycling, reduce energy consumption, and shape fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In the following, the present invention will be further described in conjunction with the accompanying drawings and specific embodiments, so as to understand more clearly the technical idea claimed in the present invention.

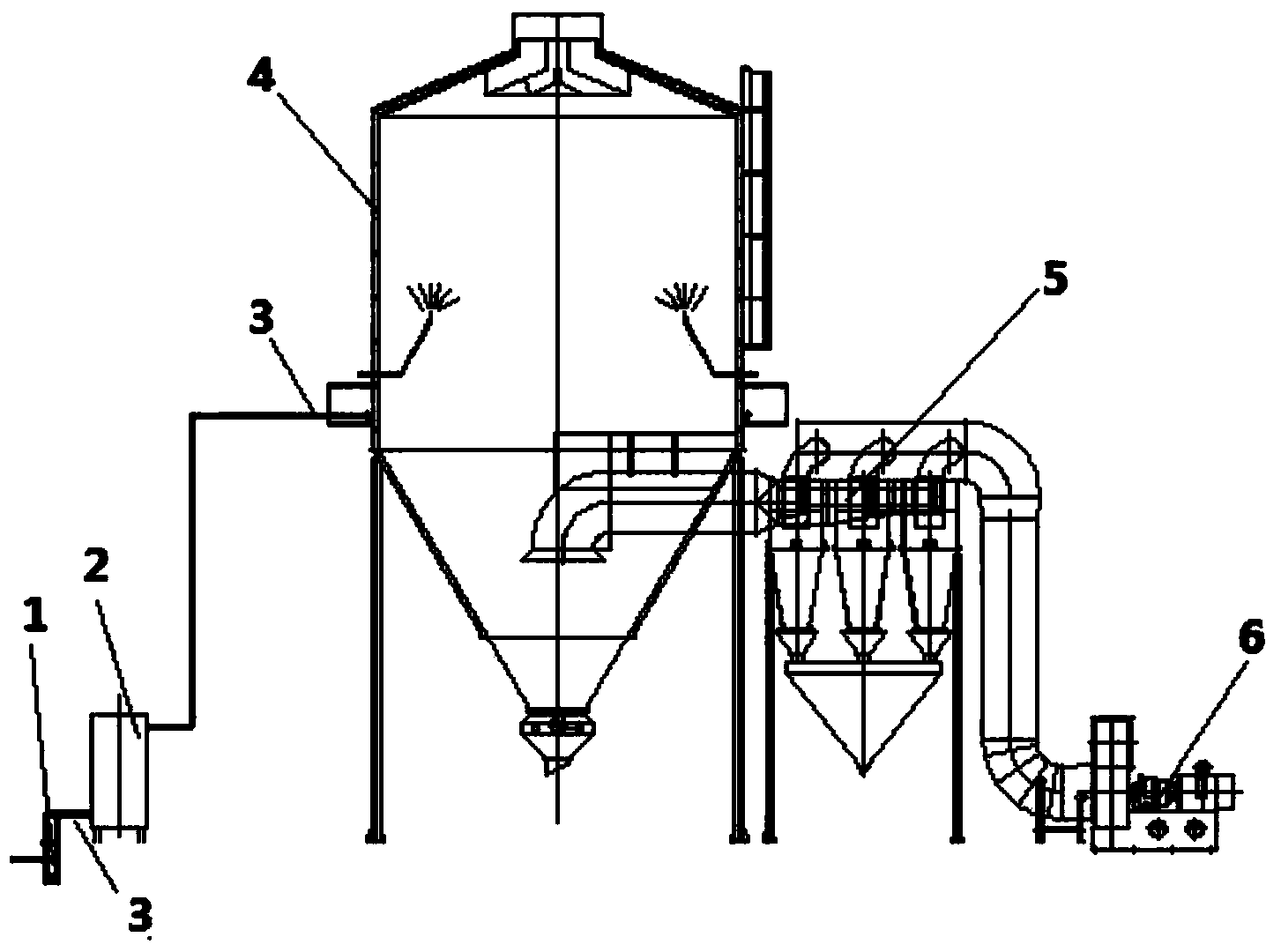

[0014] Such as figure 1 Shown is the equipment used for the energy-saving new ceramic slurry granulation process of the present invention, including a plunger pump 1 for pumping ceramic slurry, a heat exchanger 2 for preheating the ceramic slurry and a spray Tower 4, the plunger pump 1 is connected to the heat exchanger 2 through the slurry pipe 3, and the heat exchanger 2 is also connected to the nozzle of the spray tower 4 through the slurry pipe 3; the other side of the spray tower 4 is also provided with a The cyclone dedusting device 5 for evaporating moisture in the spray tower 4 and discharging the fine dust and tail gas in the spray tower 4 is connected with an induced draft fan 6 .

[0015] The present invention is a novel energy-saving c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com