Diatomite-based environmentally friendly glaze for interior wall tiles and interior wall tiles prepared using the glaze

A diatomaceous earth, environmental protection technology, applied in the field of inorganic materials, can solve the problem of no products, etc., and achieve the effect of good adsorption performance and large contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

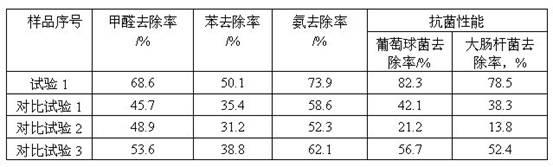

Examples

Embodiment 1

[0019] Diatomite-based environmentally friendly interior wall bricks, the raw materials of the green body are: 850 g of diatomite, 60 g of kaolin, 50 g of quartz, 40 g of bauxite, 25 g of sodium hexametaphosphate, 15 g of polyvinyl alcohol, and 1000 g of water; Mix all ingredients and grind to D 50 =6.8μm, sieve through a 60-mesh sieve to remove iron, granulate, shape at 45MPa, and calcined at 1030°C for 2 hours to obtain the diatomite-based environmentally friendly interior wall brick body.

[0020] Diatomite-based environmentally friendly interior wall tiles, the raw materials of the glaze are: 75g of diatomite, nano-TiO 2 / Tourmaline composite material 16g, feldspar 5g, kaolin 4g, sodium metasilicate 3g, water 120g, put each raw material into the grinder and grind until D 50 =4.8μm, after passing through a 80-mesh sieve, it is a paste-like glaze. The prepared glaze is poured on the surface of the green body, dried at 45°C for 24 hours, and calcined at 820°C for 2 hours t...

Embodiment 2

[0023] Diatomite-based environmental protection interior wall bricks, the raw materials of the body are: 900g of diatomite, 60g of kaolin, 40g of feldspar, 20g of sodium polyacrylate, 15g of carboxymethyl cellulose, 1200g of water, and 150g of sawdust. When preparing, mix the raw materials, put them into the grinder and grind until D 50 =6μm, granulated after passing through a 60-mesh sieve, shaped under a pressure of 55MPa, and calcined at 1000°C for 3 hours to obtain a diatomite-based environmentally friendly interior wall brick body.

[0024] Diatomite-based environmentally friendly interior wall tiles, the raw materials of the glaze are: 82g of diatomite, nano-TiO 2 / Tourmaline composite material 12g, feldspar 4g, talc 2g, pigment dark grass green 0.8g, polyacrylic acid ammonium 3g, water 100g, put each raw material into the grinder and grind until D 50 =5.2μm, after passing through a 120-mesh sieve, it is a paste-like glaze. The prepared glaze is poured on the surface o...

Embodiment 3

[0027] Diatomite-based environmental protection interior wall bricks, the raw materials of the body are: 800g diatomite, 80g kaolin, 80g bauxite, 40g feldspar, 20g sodium metasilicate, 15g carboxymethyl cellulose, 1000g water g, plus 250g of stearic acid. When preparing, mix the raw materials, put them into the grinder and grind until D 50 =8.3μm, granulated after passing through a 60-mesh sieve, molded under a pressure of 65MPa, and calcined at 1050°C for 2 hours to obtain a diatomite-based environmentally friendly interior wall brick body.

[0028] Diatomite-based environmentally friendly interior wall tiles, the raw materials of the glaze are: 82g of diatomite, nano-TiO 2 / Tourmaline composite material 14g, quartz 4g, pigment silver ash 0.5g, sodium tripolyphosphate 2.5g, water 100g, put each raw material into the grinder and grind until D 50 =4.8μm, after passing through a 100-mesh sieve, it is a slurry glaze. The prepared glaze is poured on the surface of the diatomite...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com