Glass ink for ink-jet printing and preparation method of glass ink

A glass ink and inkjet printing technology, applied in ink, applications, household appliances, etc., can solve problems such as nozzle clogging, wear, and poor dispersion, and achieve low production costs, high safety factor, and good stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

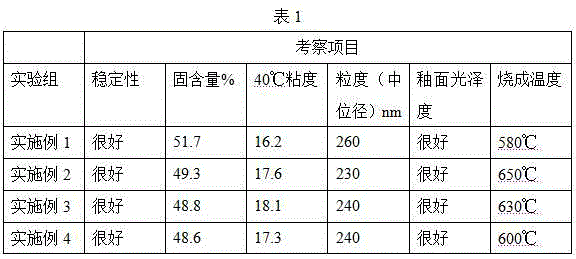

Examples

Embodiment 1

[0058] (1) Preparation of glass glaze

[0059] The components of the low-temperature glass glaze are calculated by weight percentage as follows: 30%SiO 2, 25%ZnO, 4.5%CaO+MgO, 5%BaO, 10%B 2 o 3 , 6%Al 2 o 3 , 8%TiO 2 , 2.0%ZrO 2 , 6.5%K 2 O+Na 2 O, 3% Li 2 O;

[0060] Weigh the raw materials of the above formula according to weight percentage and mix them evenly, then place them in a melting furnace and melt the batch at 1200°C;

[0061] The melted batch material was water-quenched and dried, and ball-milled by a ball mill for 4 hours.

[0062] (2) Preparation of co-solvent

[0063] The components of the glass ink co-solvent are calculated as follows by weight percentage: tripropylene glycol methyl ether 20%, propylene glycol monobutyl ether 10%, diethylene glycol monobutyl ether 55%, polyethylene glycol 5%, AD-8150 10%;

[0064] The above-mentioned solvent raw materials were weighed by weight percentage, and dispersed for 30 minutes with a high-speed disperser.

...

Embodiment 2

[0070] (1) Preparation of glass glaze

[0071] The components of the low-temperature glass glaze are calculated by weight percentage as follows: 55%SiO 2 , 9.5%ZnO, 5.7%CaO+MgO, 5.0%BaO, 10.3%B 2 o 3 , 1.0%Al 2 o 3 , 0.5%TiO 2 , 11%K 2 O+Na 2 O, 2.0% Li 2 O;

[0072] Weigh the raw materials of the above formula according to the weight percentage and mix them evenly, then place them in the furnace and melt the batch at 1300°C;

[0073] The melted batch material was water-quenched and dried, and ball-milled by a ball mill for 4 hours.

[0074] (2) Preparation of co-solvent

[0075] The components of glass ink co-solvent are calculated as follows by weight percentage: tripropylene glycol methyl ether 10%, ethylene glycol ether 15%, propylene glycol monomethyl ether 15%, diethylene glycol monobutyl ether 45%, polyethylene glycol 5% , AD-8150 10%;

[0076] Weigh the above co-solvent raw materials by weight percentage, and disperse for 30 minutes with a high-speed disper...

Embodiment 3

[0083] (1) Preparation of glass glaze

[0084] The components of the low-temperature glass glaze are calculated by weight percentage as follows: 45%SiO 2 , 5.0%ZnO, 1.0%CaO+MgO, 4.0%SrO, 33%B 2 o 3 , 4.5%Al 2 o 3 , 0.5%TiO 2 , 7.0ZrO 2 , 5.0%K 2 O+Na 2 O, 1.0% Li 2 O Weigh the raw materials of the above formula according to weight percentage and mix them evenly, then place them in a melting furnace and melt the batch at 1250°C;

[0085] The melted batch material was water-quenched and dried, and ball-milled by a ball mill for 4 hours.

[0086] (2) Preparation of co-solvent

[0087] The components of the cosolvent of the glass ink are calculated as follows by weight percentage: 10% propylene glycol butyl ether, 15% propylene glycol n-propyl ether, 3% ethyl acetate, 30% polypropylene colloidal emulsion, 7% isobutanol tripropylene glycol methyl ether, diglycol Alcohol monobutyl ether 25%, AD-1310 10%;

[0088] Weigh the above co-solvent raw materials by weight percent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com