Antiseep glaze material and glair for Ruyao kiln package container and preparing method thereof

A packaging container and anti-leakage technology, applied in the field of ceramic manufacturing, can solve the problems of unfavorable cleaning and sanitation, easy storage of flakes and dirt, leakage of liquid substances, etc., achieve considerable economic benefits, expand market space, and improve anti-seepage. leakage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

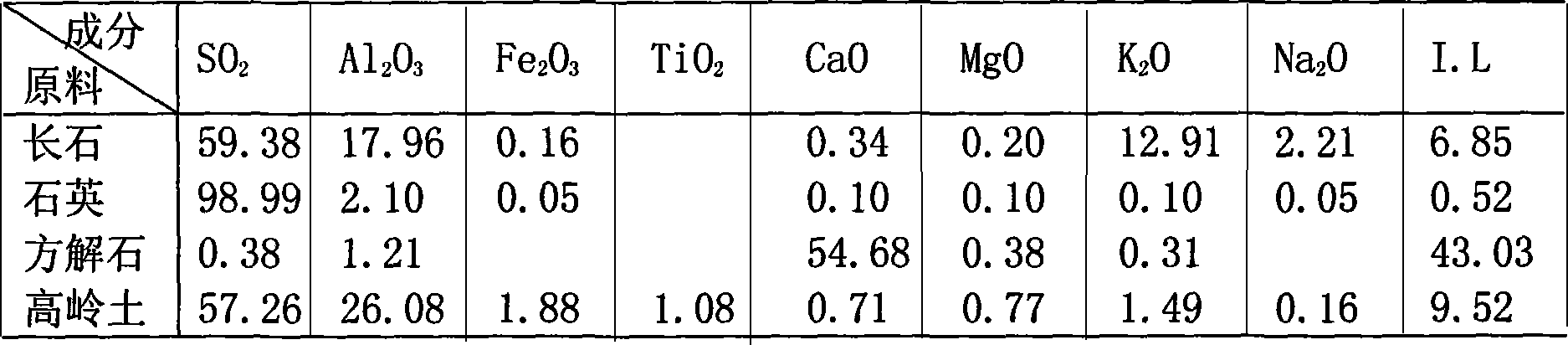

[0020] Embodiment 1 A kind of anti-leakage glaze for Ru porcelain packaging container, including the following glaze raw materials in terms of weight percentage: feldspar 20%, quartz 12%, calcite 20%, kaolin 48% (see the chemical composition and content of each raw material. Table 1).

[0021] The method for preparing the anti-leakage glaze slurry for Ru porcelain packaging containers with the above-mentioned glaze formula includes the following process steps: ① checking and rinsing the anti-leakage glaze raw materials; The raw material formula of the anti-leakage glaze is to weigh each raw material, mix and prepare the glaze; ④ add water to the glaze according to the weight ratio of glaze: water = 1: 1.5, process and grind it into glaze slurry with a ball mill; ⑤ Pass through a 250-mesh sieve (the remainder of the sieve is less than 0.01%) to remove iron.

[0022] The content of each component in the obtained glaze slurry is roughly as follows: 12% of feldspar, 7.2% of quart...

Embodiment 2

[0029] Example 2 An anti-leakage glaze for Ru porcelain packaging containers, including the following glaze raw materials by weight percentage: 30% feldspar, 6% quartz, 25% calcite, 38.5% kaolin, and 0.5% iron oxide pigment.

[0030] The method for preparing the anti-leakage glaze slurry for the Ru porcelain packaging container with the above-mentioned glaze formula includes the following process steps: ① checking and rinsing the anti-leakage glaze raw materials; ② grinding each glaze raw material into fine powder with a Raymond mill; ③ Weigh the fine powder of each raw material according to the above ratio, mix and prepare the glaze; ④ add water to the glaze according to the weight ratio of glaze: water = 1: 1.5 and stir;

[0031] The content of each component in the obtained glaze slurry is roughly as follows: 18% of feldspar, 3.6% of quartz, 7.2% of calcite, 23% of kaolin, 0.3% of iron oxide pigment, and the rest is water.

[0032] A method for manufacturing an anti-leakage...

Embodiment 3

[0038] Embodiment 3 A kind of anti-leakage glaze for Ru porcelain packaging container, including the following glaze raw materials in terms of weight percentage: 16% feldspar, 17% quartz, 12% calcite, 55% kaolin (see the chemical composition and content of each raw material. Table 1).

[0039] The method for preparing the anti-leakage glaze slurry with the above glaze formulation is basically the same as in Example 1, the difference is that water is added to the glaze according to the weight ratio of glaze: water = 1: 1, and after grinding into the glaze slurry, pass 150 Mesh sieve (residue less than 0.02%).

[0040] The content of each component in the obtained glaze slurry is roughly as follows: feldspar 8%, quartz 8.5%, calcite 6%, kaolin 27.5%, and the rest is water.

[0041] The manufacturing method of the anti-leakage porcelain packaging container is the same as that in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com