Low temperature rapid firing ceramic tile and production process

A production process and a technology for ceramic bricks, which are applied in the field of low-temperature rapid firing of ceramic bricks and production processes, can solve problems such as large limitations, and achieve the effects of reducing fuel consumption, reducing energy consumption for firing, and shortening firing cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

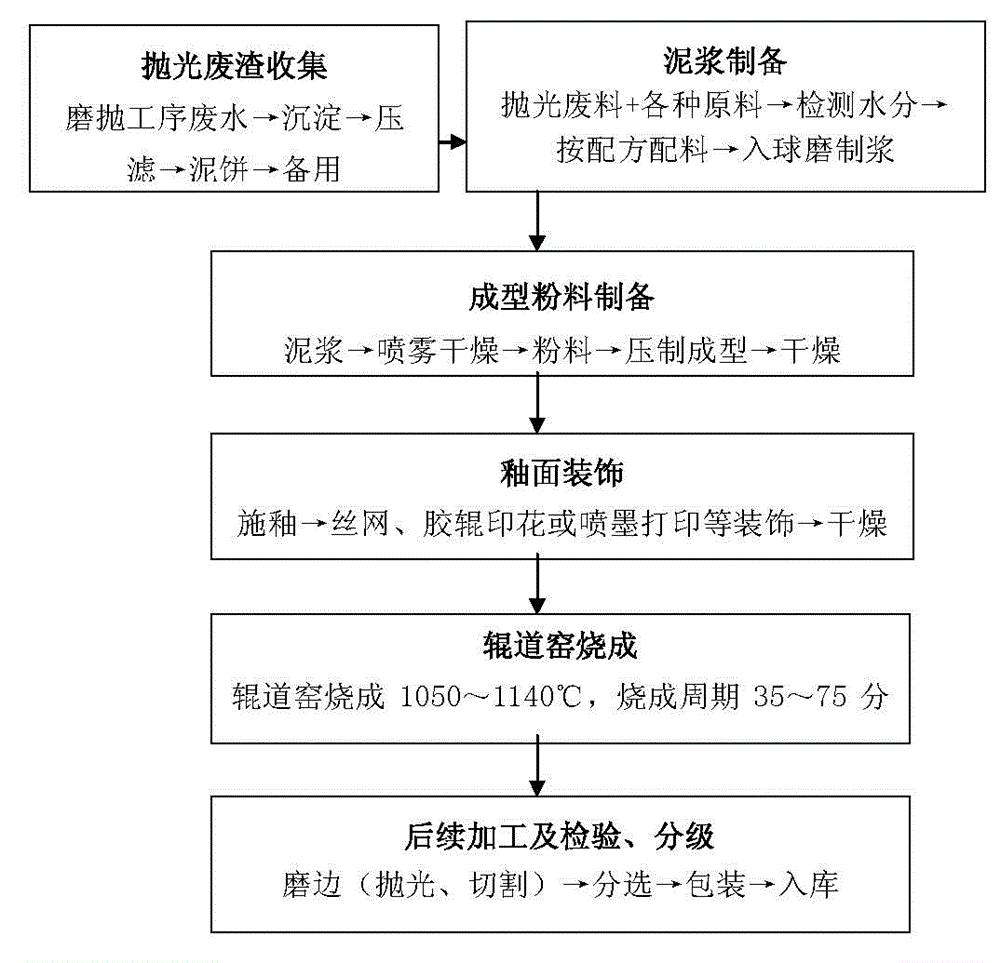

[0052] [Example 1] Low-temperature rapid firing ceramic tiles and the first production process:

[0053] ⑴Collect the spare polishing waste slag to detect the moisture content, mix the ingredients according to the weight percentage, and convert it into a dry base blank formula: 65% polishing waste slag, 20% clay, 13% porcelain sand, 2% wollastonite; admixture: carboxymethyl fiber Sodium plain 0.08%, trimer 0.06%, sodium humate 0.03%, water glass 0.25%; put the ingredients into a ball mill, add water and wet grind into a slurry, the particles larger than 40 microns in the slurry are less than 2.30% (that is, the remaining 2.3% of the 325 mesh sieve ), after being sieved and iron-removed, it is stored in the slurry pool for later use.

[0054] ⑵ Spray drying to prepare powder, the moisture content of the powder is controlled at 6% to 7%, the bulk density is 0.98%, dry pressing is made into adobe of 330 mm×330mm, thickness 9.6 mm±0.3mm and dried, and the surface of the dried adob...

Embodiment 2

[0056] [Example 2] Low-temperature rapid firing ceramic tiles and the second production process:

[0057] (1) Mix 50% of polishing waste residue, 23% of clay, 17% of porcelain sand, 3% of wollastonite, 2% of bentonite, and 5% of high-temperature potash sand, and make pulp by ball milling; add 0.1% of sodium carboxymethyl cellulose, 0.2 %, wet ball milling into mud, the detection fineness greater than 40 microns is 2.14% (325 mesh sieve remaining 2.14%), the mud is transported to the spray tower after iron removal and sieving, and dried into powder for storage for later use;

[0058] ⑵Using the existing KD3800 hydraulic brick press in the production line, the powder is pressed into bricks with a specification of 600×600mm and a thickness of 10.0±0.3mm for drying, and the bottom glaze, surface glaze, and inkjet decoration are applied and conveyed by the multifunctional decoration line It is fired in a roller kiln at a firing temperature of 1140°C and a firing cycle of 60 minutes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com