Method and device for rapidly detecting loosening of bolt of iron tower

A technology for bolt loosening and detection methods, which is applied in measuring devices, geophysical measurement, seismology, etc., can solve the problems of heavy inspection workload, easy missing inspection, labor-intensive and time-consuming, etc., to save manpower and material resources and meet efficiency And the effect of accuracy and fast detection speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

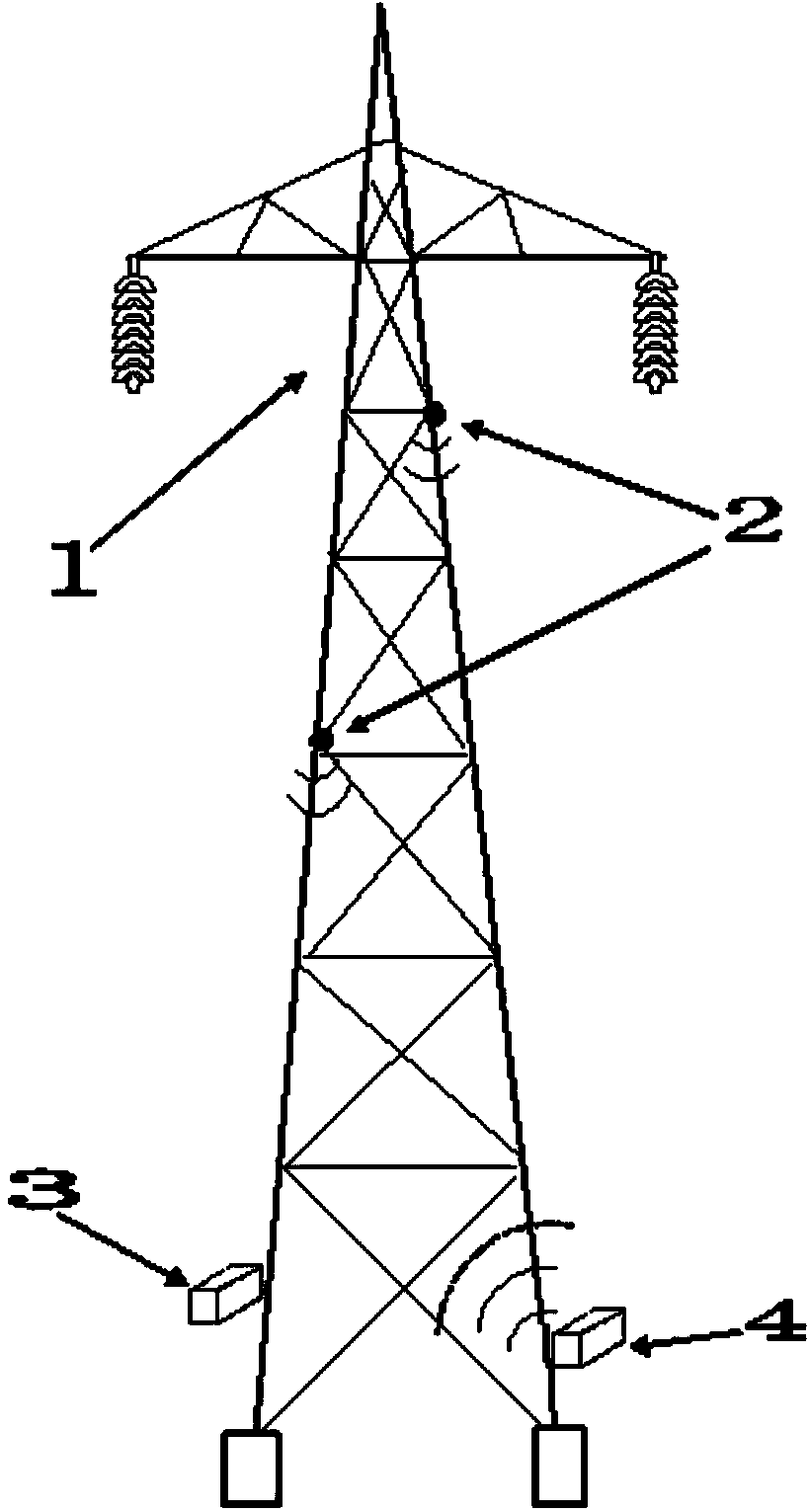

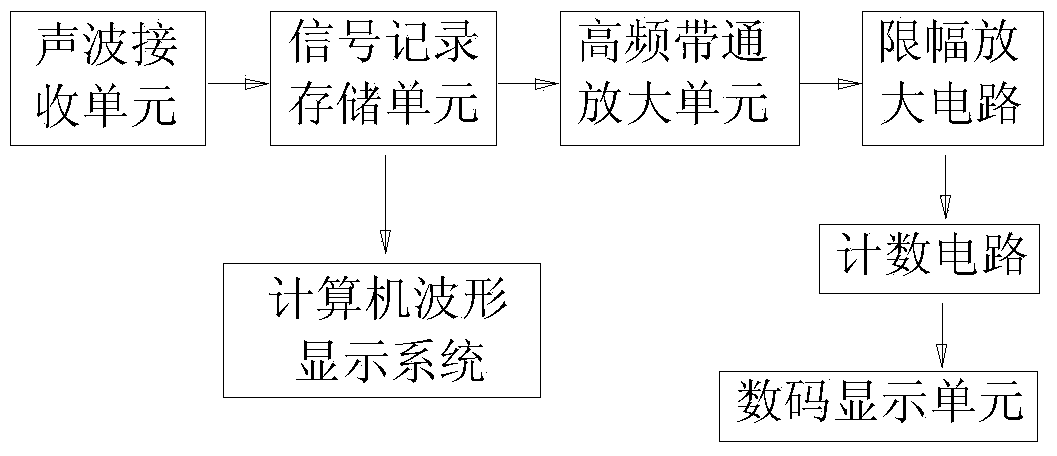

[0021] See figure 1 , is a schematic diagram of the detection state of the embodiment of the present invention. In the present invention, the iron tower 1 is vibrated by adding a mechanical oscillation source 4, and the loose bolts 2 and the tower material parts are excited to resonate or vibrate, resulting in secondary impact sound, which is passed through the vibration frequency receiving device 3. The sound wave is received and converted into an electrical signal, and the electrical signal is analyzed in two ways. One is to display the sound waveform and analyze the waveform by observing the waveform; the other is to analyze the value through the counting method, so as to quickly determine Whether there are loose bolts on the iron tower, the specific implementation includes three steps:

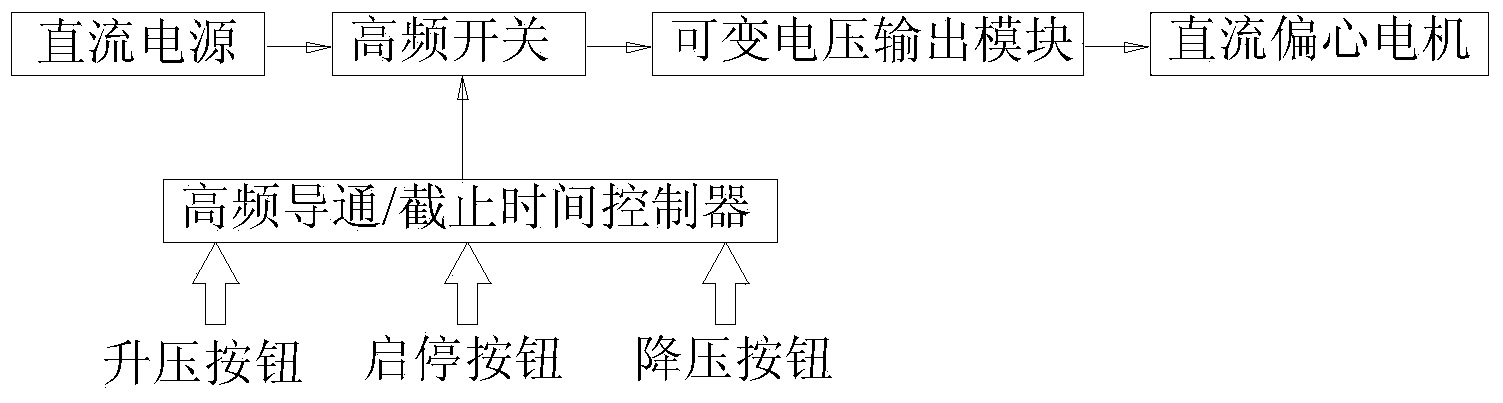

[0022] 1) Select the rotary vibration motor as the mech...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com