Built-in rail-changing sliding window

A technology of sliding windows and window strips, which is applied in the field of sliding windows, can solve the problems of affecting the sealing effect, short service life, rainwater penetration and sliding, etc., and achieve the effect of improving vehicle grade, improving comfort and increasing safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

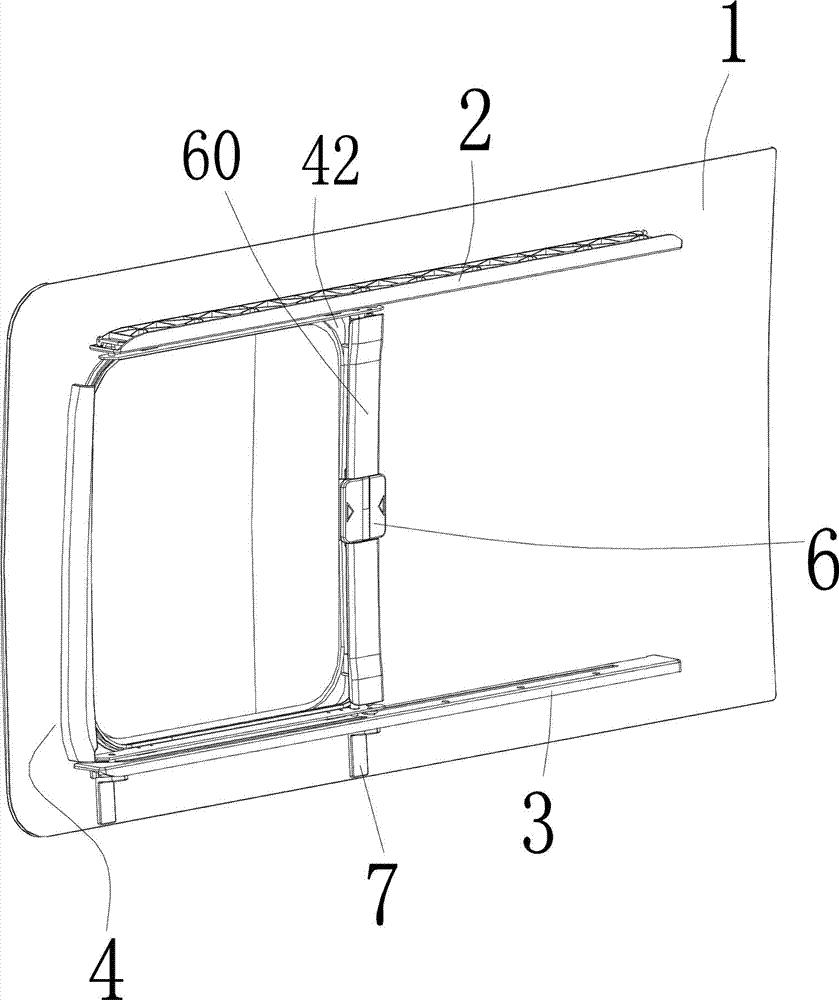

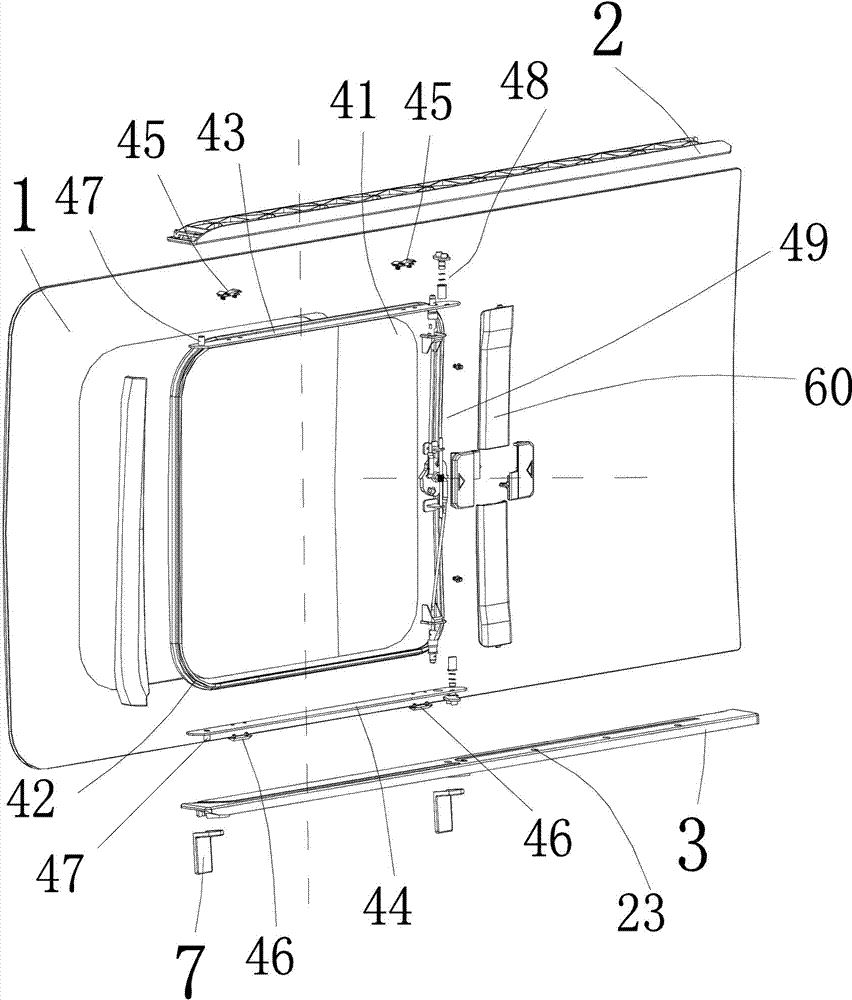

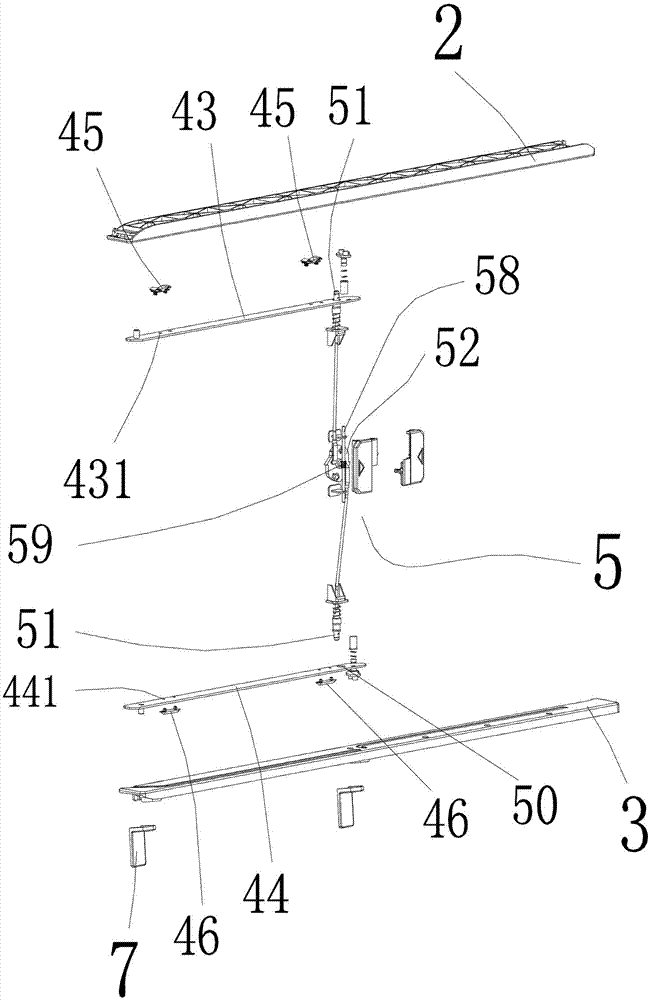

[0063] Embodiment 1, the built-in rail-changing sliding window includes upper and lower rails (2, 3) fixed on the inner side of the outer window frame (1), and movable between the upper and lower rails (2, 3) window (4), the movable window (4) includes upper and lower window strips (43, 44), the upper liner (45) installed on the upper window bar (43) and the lower liner (46) on the lower window bar (44) and the same end of the upper and lower window bars (43, 44) The sliding column (47) is composed of a rail-changing slider (48) inserted at the other same end of the upper and lower window bars (43, 44);

[0064] The upper and lower rails (2, 3) are evenly divided into two sections of chute, the end of the first section of chute (21) corresponding to the sliding post (47) is an arc, and the end of the first section of chute (21) corresponding to the sliding rail slider (48) is curved. The end of the second section of the chute (22) is hook-shaped; the end of the second section...

Embodiment approach 2

[0066] Embodiment 2, based on Embodiment 1, the upper pad (45) is composed of an M-shaped compensating elastic member (451) at the upper end, and a pad (452) connected with the compensating elastic member (451) at the lower end, There is a bullet-assisted metal strip (454) under the wings (453) that make up the two ends of the elastic member (451), and a quick positioning pin fixed on the upper window liner hole (431) extends below the pad (452). column (455), the column body of the quick positioning column (455) is in the shape of an inverted tower.

[0067] The upper surface of the compensating elastic part (451) is pushed against the rail surface of the upper slide rail (2). After the movable window (4) has been used for a long time, the elastic part (451) can be compensated under the action of the elastic metal strip (454). Both side wings (453) keep an elastic overhead state.

[0068] The quick positioning post (455) is in the shape of an inverted tower to ensure that th...

Embodiment approach 3

[0069] Embodiment 3, based on Embodiment 1, the surface of the lower gasket (46) has a tubular shape, and the other side of the gasket extends outwards with a positioning column (461) fixed to the gasket hole (441) of the lower window strip , the surface of the lower pad (46) is pressed against the surface of the lower rail (3).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com