Three-way joint of protection net

A technology of three-way joint and protective net, applied in the direction of fixed grille, etc., can solve the problems of easy loosening of the frame, detachment of adjacent three-section frames, easy softening and melting, etc., so as to improve the connection reliability and the connection tightness. , the effect of eliminating security risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

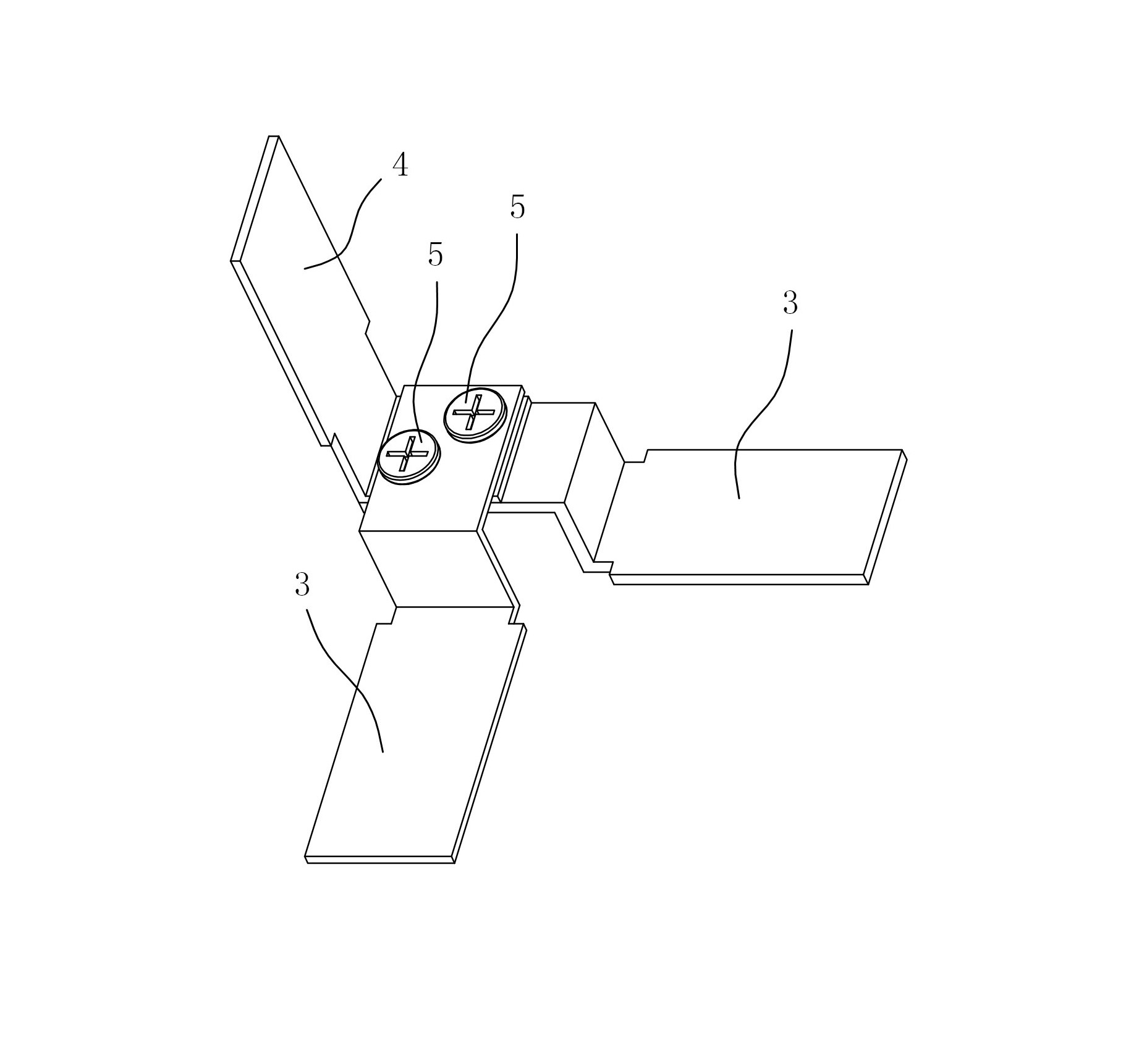

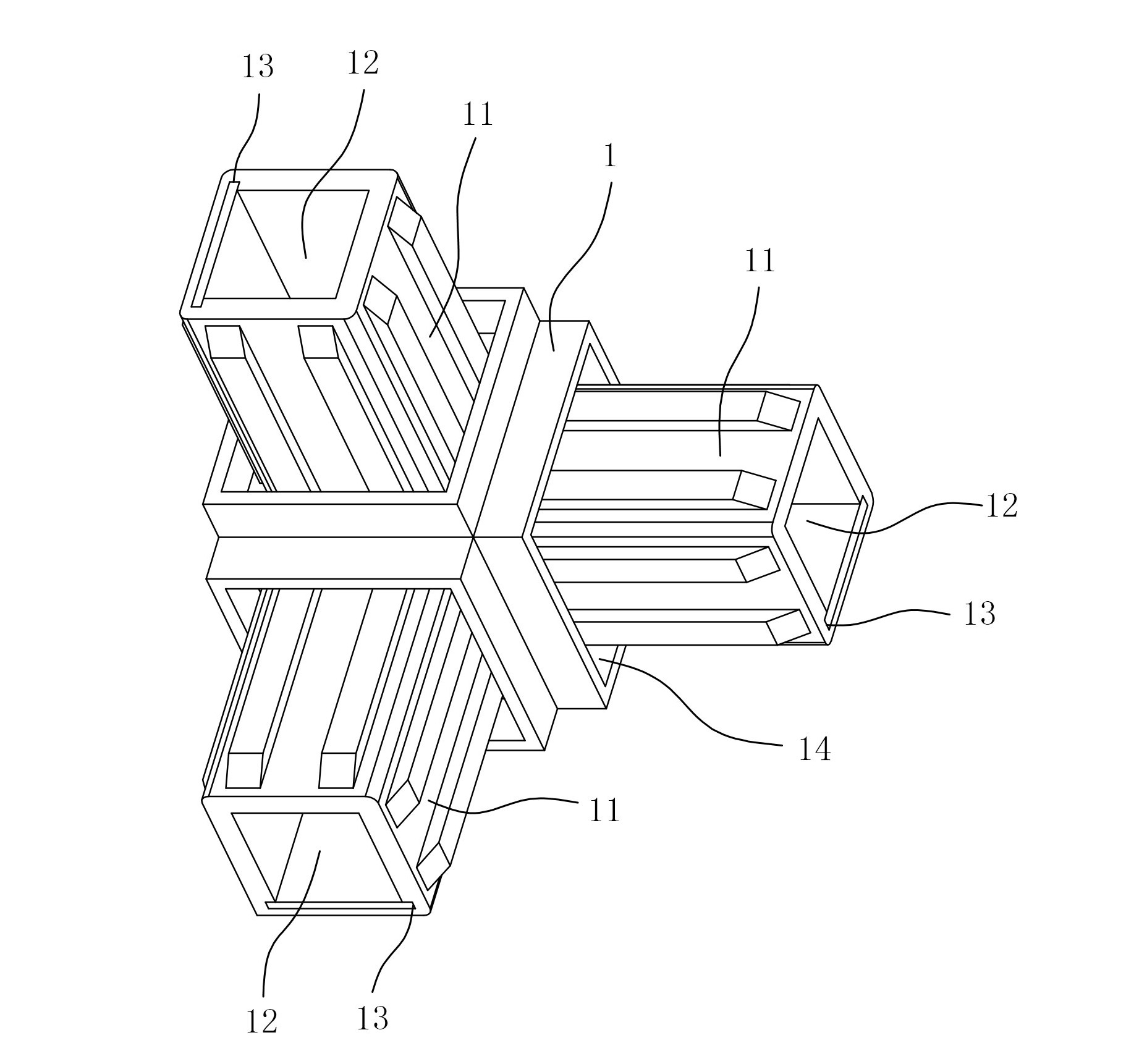

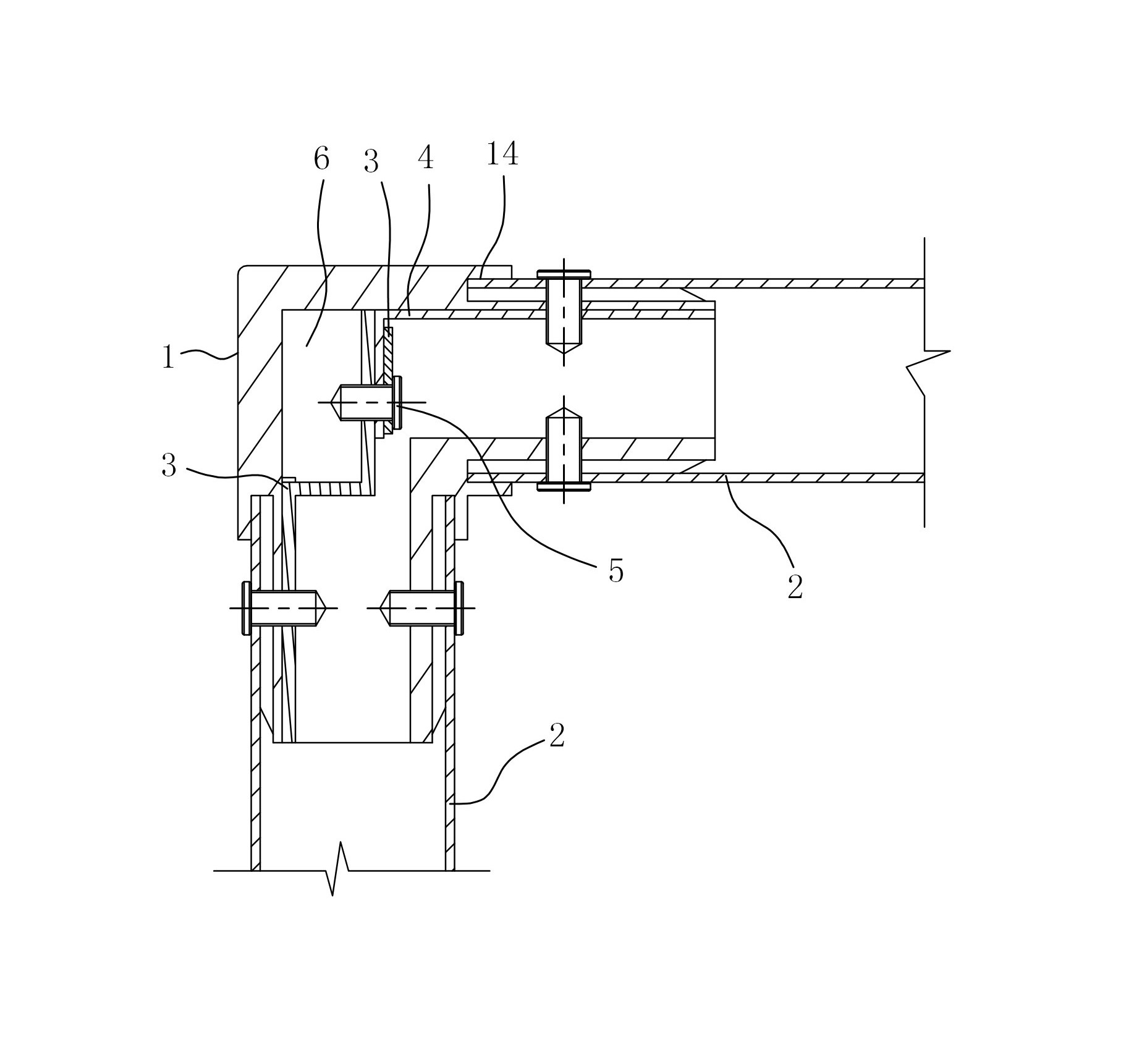

[0018] Figure 1 to Figure 3 A protective net tee joint of the present invention is shown, the tee joint comprises a nylon tee joint body 1, the nylon tee joint body 1 is provided with three sections of joints 11 for connecting the frame 2 of the protective net, and the three-section joint 11 is respectively provided with an inner hole 12, and the three inner holes 12 are connected with each other. Each inner hole 12 is inserted into a metal plate, and the three metal plates are tightly connected. When the nylon part is aging, the frame 2 of the protective net still passes through the three pieces. The metal plate connection can prevent the frame 2 of the adjacent protective net from detaching, greatly improving the connection reliability of the frame 2 of the protective net, so that the protective net still has a protective effect; when the nylon part is softened and melted by fire, the metal plate will The connection to the frame 2 of the protective net is still not affected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com