Multifunctional cabinet door hinge

A multi-functional cabinet door technology, which is applied to hinges with pins, door/window accessories, construction, etc., can solve the problems of unstable opening and closing, small opening angle, and large gap between doors, so as to achieve easy opening and closing, The effect of large opening angle and small door gap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings.

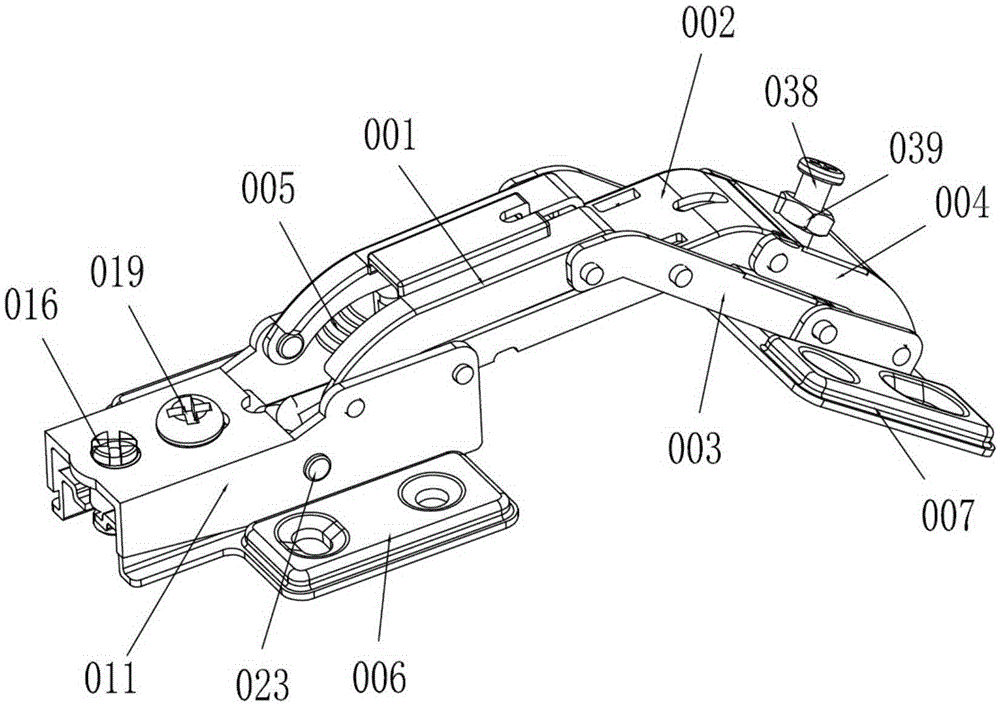

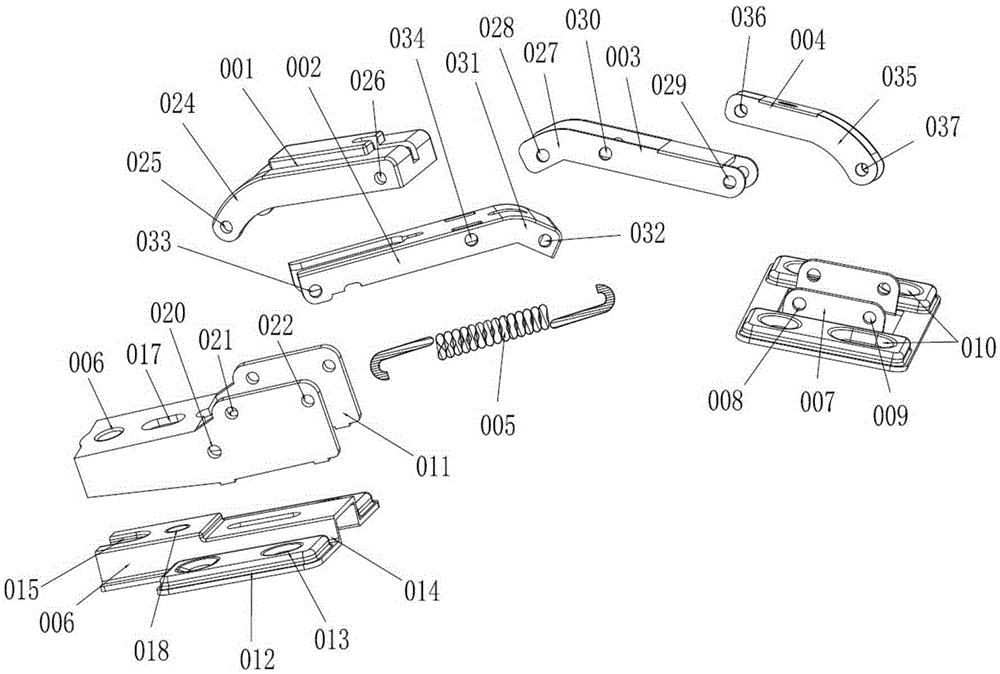

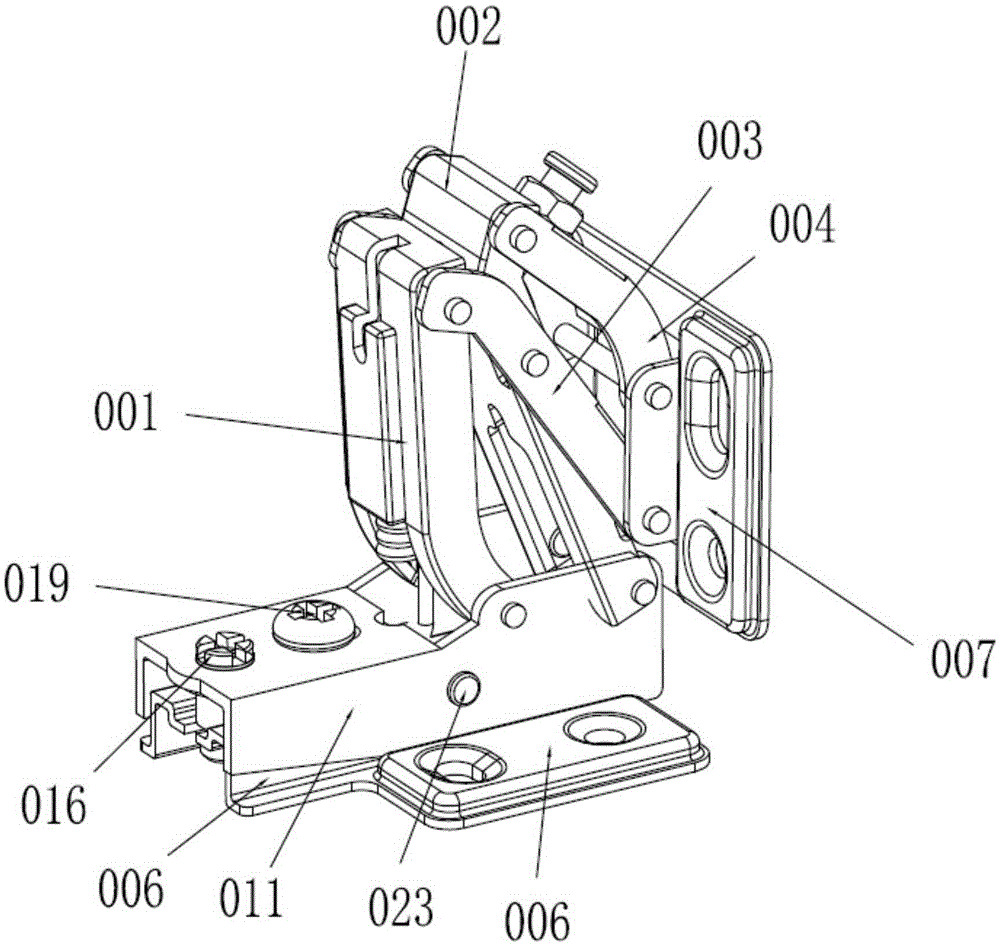

[0023] Figure 1 to Figure 3 A multifunctional cabinet door hinge according to the present invention is schematically shown.

[0024] For a multifunctional cabinet door hinge provided in this embodiment, please refer to Figure 1 to Figure 3 , including: main rotation rod 001, main rotation rod 002, transmission rod 003, transmission rod 004, tension spring 005, inner frame base 006 and outer door base 007, the outer door base 007 is provided with a second The ninth assembly hole 008 and the tenth assembly hole 009 are provided with second fixing holes 010 on the left and right sides of the outer door base 007, and an adjustable adjustment bracket 011 is provided on the inner frame base 006. The inner frame base 006 is provided with a first fixing block 012 extending to the left and right sides, the first fixing block 012 is provided with a first fixing hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com