Anti-loosing fastener

A fastener and anti-loosening technology, which is applied in the direction of threaded fasteners, locking fasteners, connecting components, etc., to achieve the effect of convenient use and easy processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Embodiments of the present invention will be specifically described below in conjunction with the accompanying drawings:

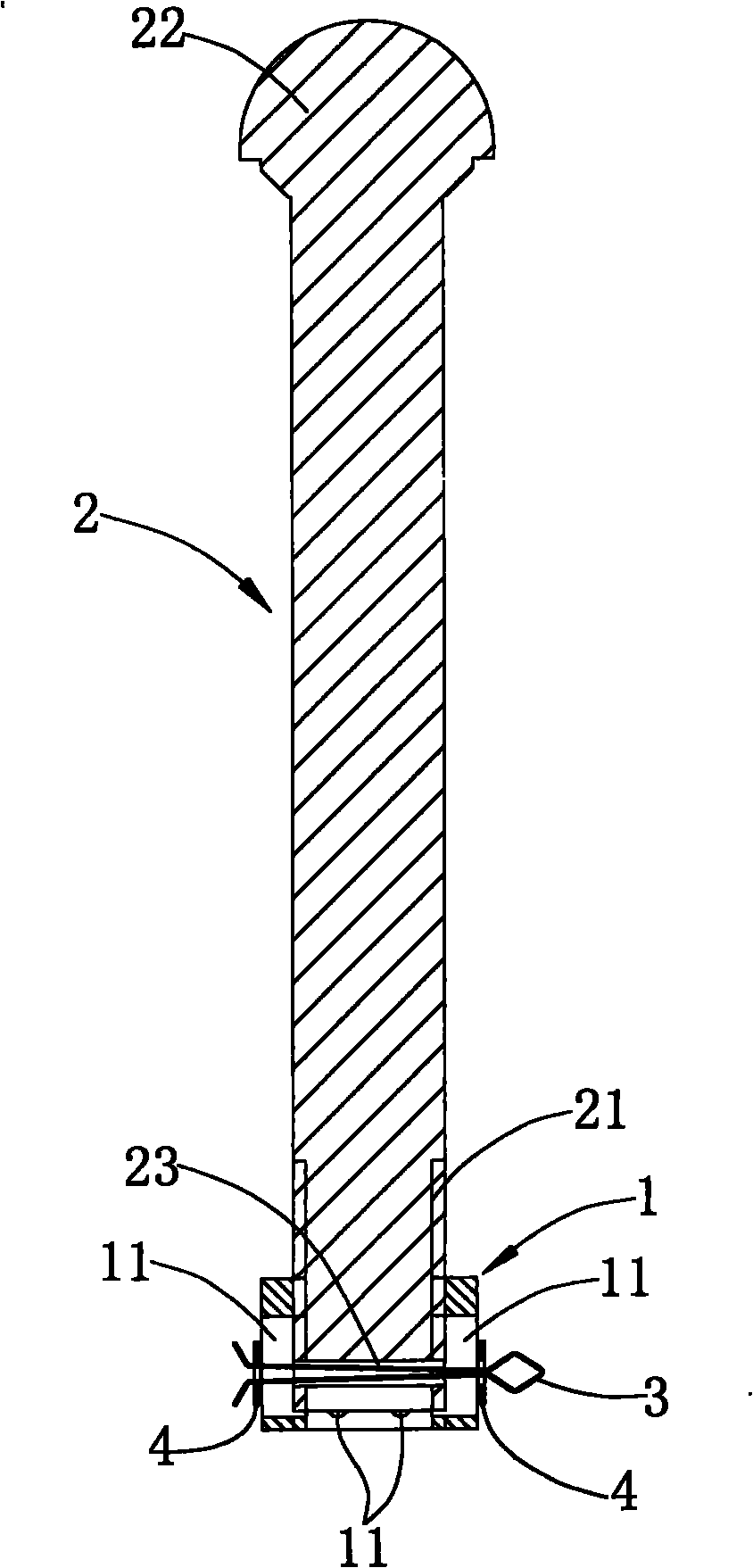

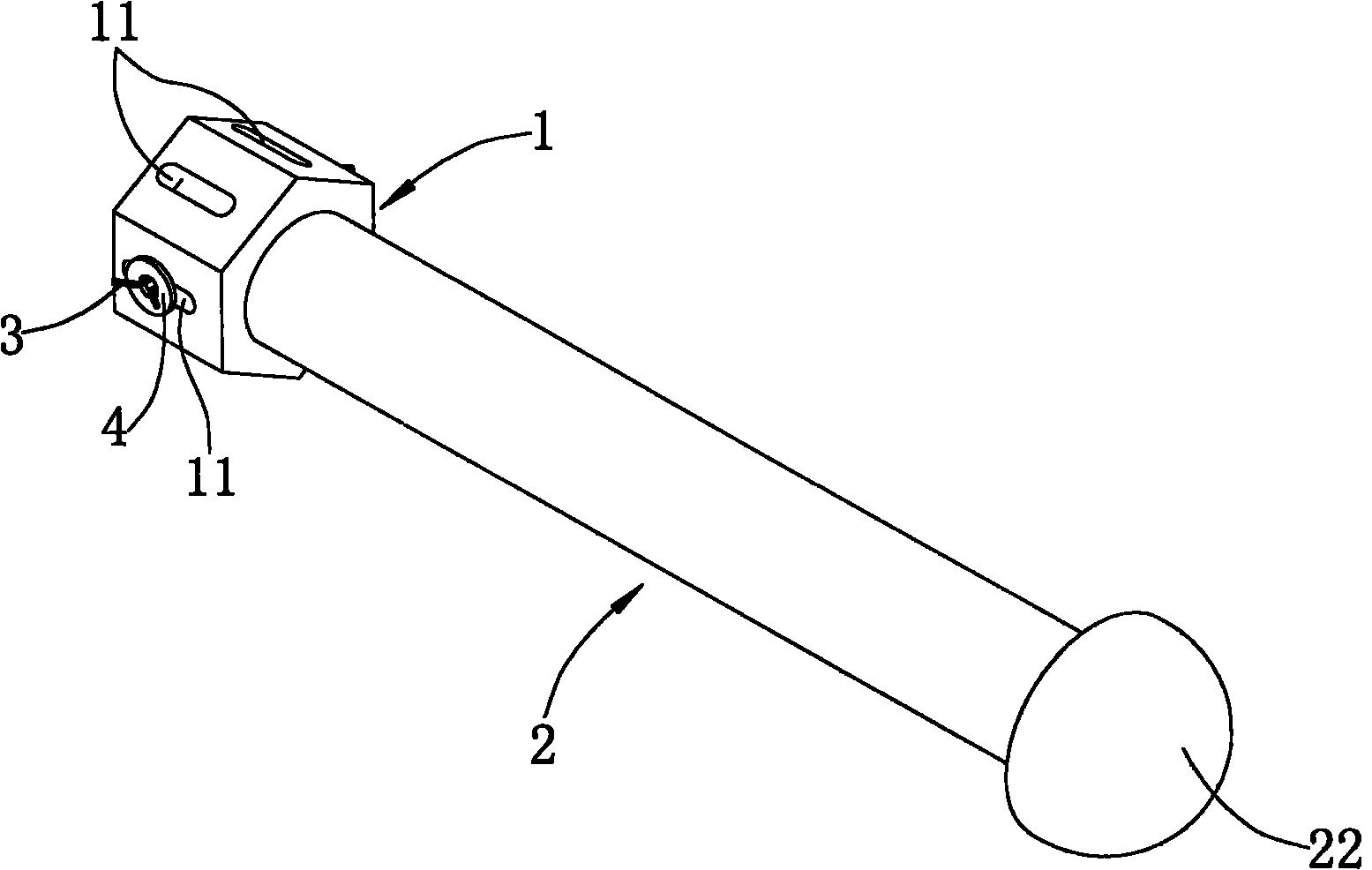

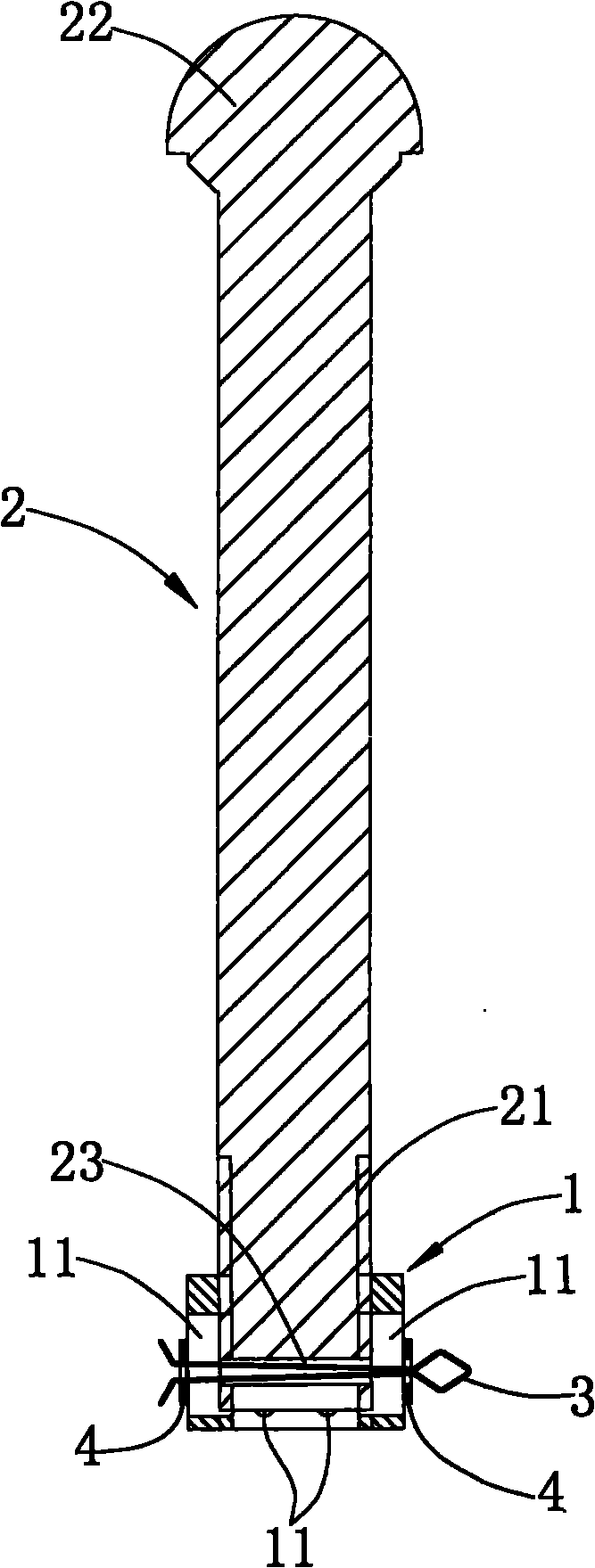

[0016] see figure 1 , figure 2 , the fastener includes a cap body 1 and a screw rod 2 screwed together, one end of the screw rod 2 is provided with an external thread 21, and the other end is provided with a plug 22, and the cap body 1 is a regular hexagonal block with an internal thread through hole in the axial direction. body, the central area of every two opposite sides in the cap body 1 is respectively opened with an axial strip hole 11 communicating with the internal thread through hole, and the axial center line of each two strip holes 11, the cap The axes of the body 1 are all in the same plane, and one end of the screw rod 2 provided with an external thread 21 is provided with a radial perforation 23 passing through the axis. In the strip hole 11, so that the cap body 1 is positioned on the screw rod 2. The two ends of the cotter pin ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com