Electric connector

A technology of electrical connectors and conductive terminals, applied in the field of electrical connectors, can solve the problems of loosening, affecting the electrical contact effect of flexible printed circuit boards, unable to ensure reliable signal transmission, etc., to achieve the effect of ensuring signal transmission.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

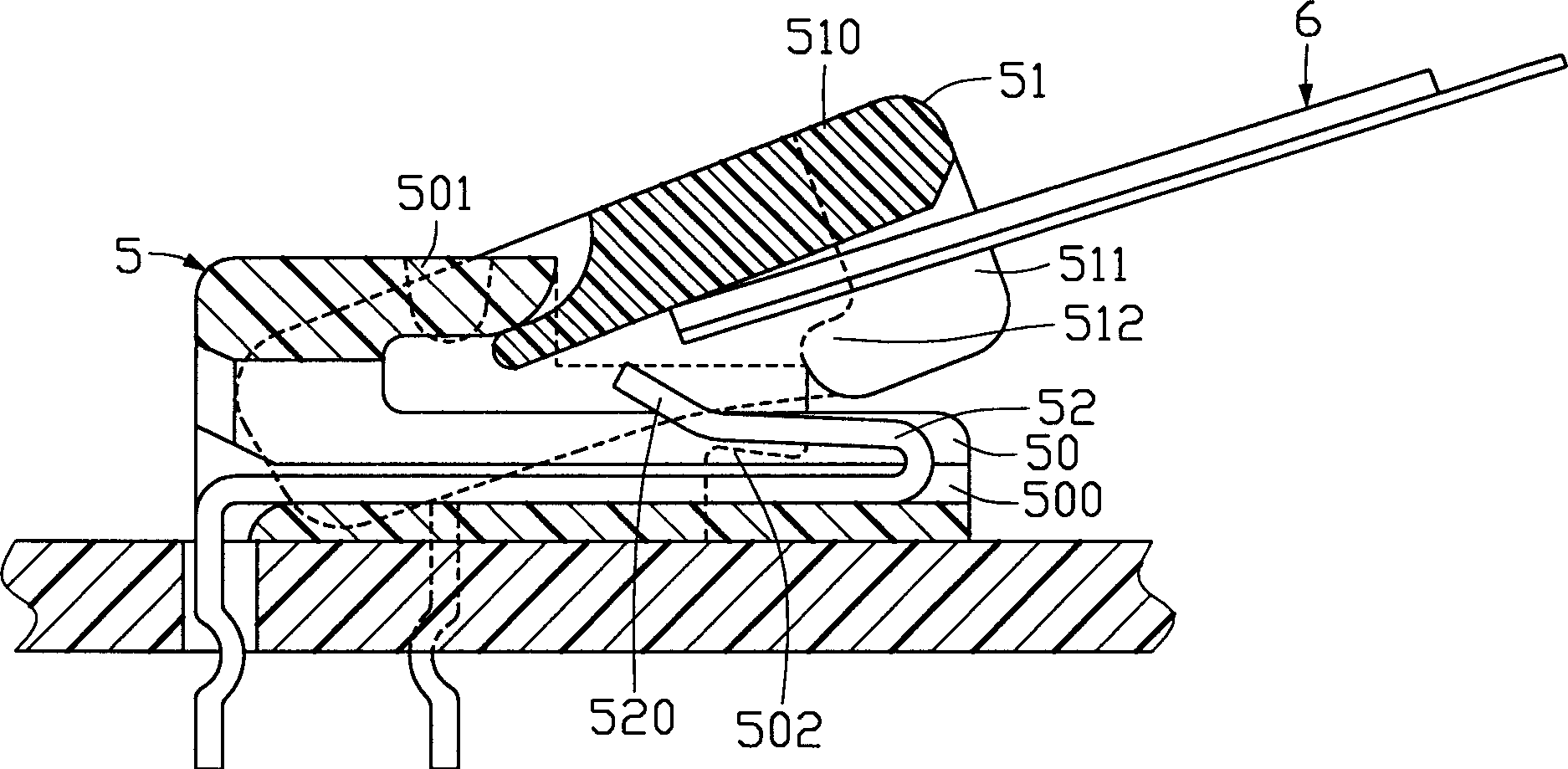

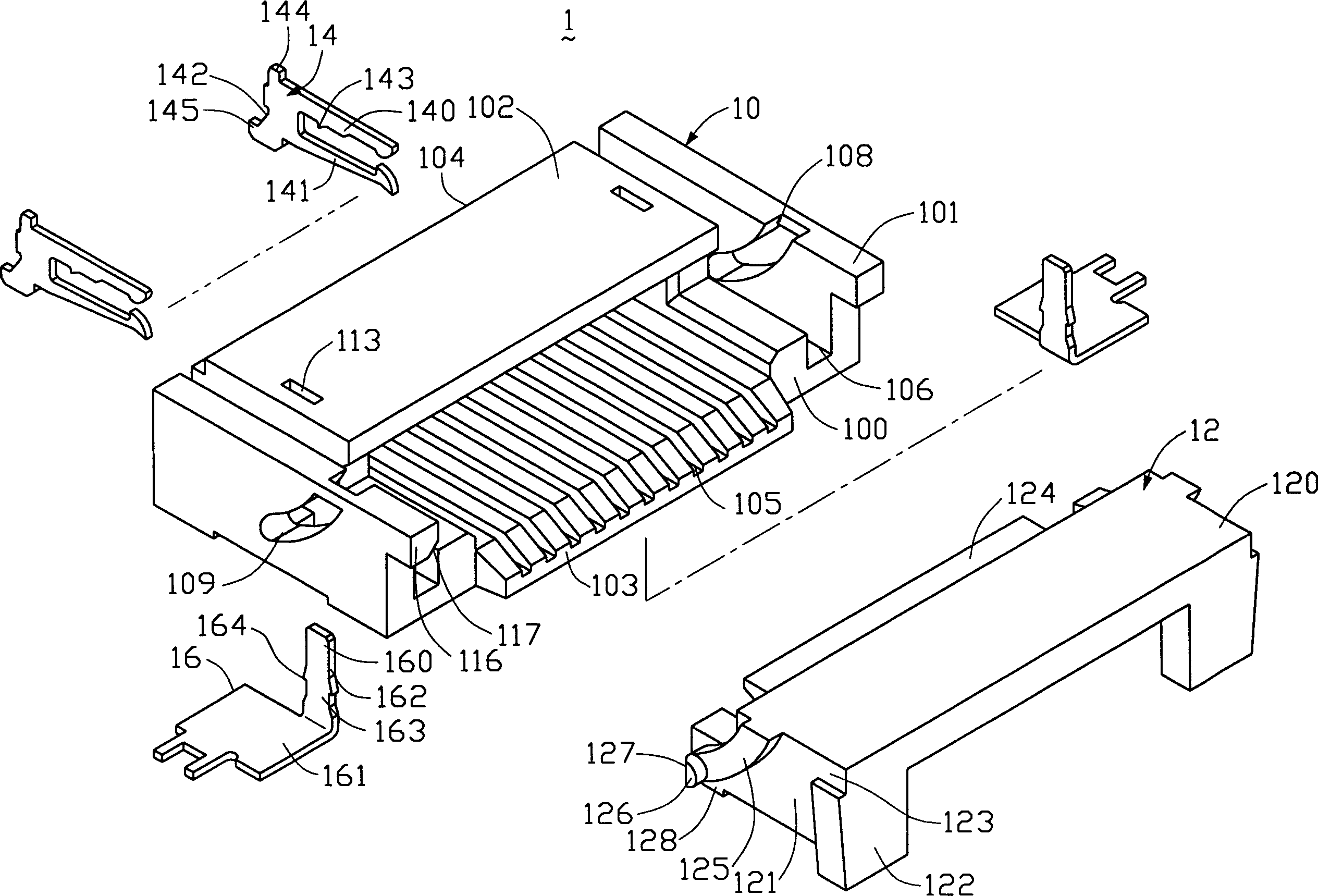

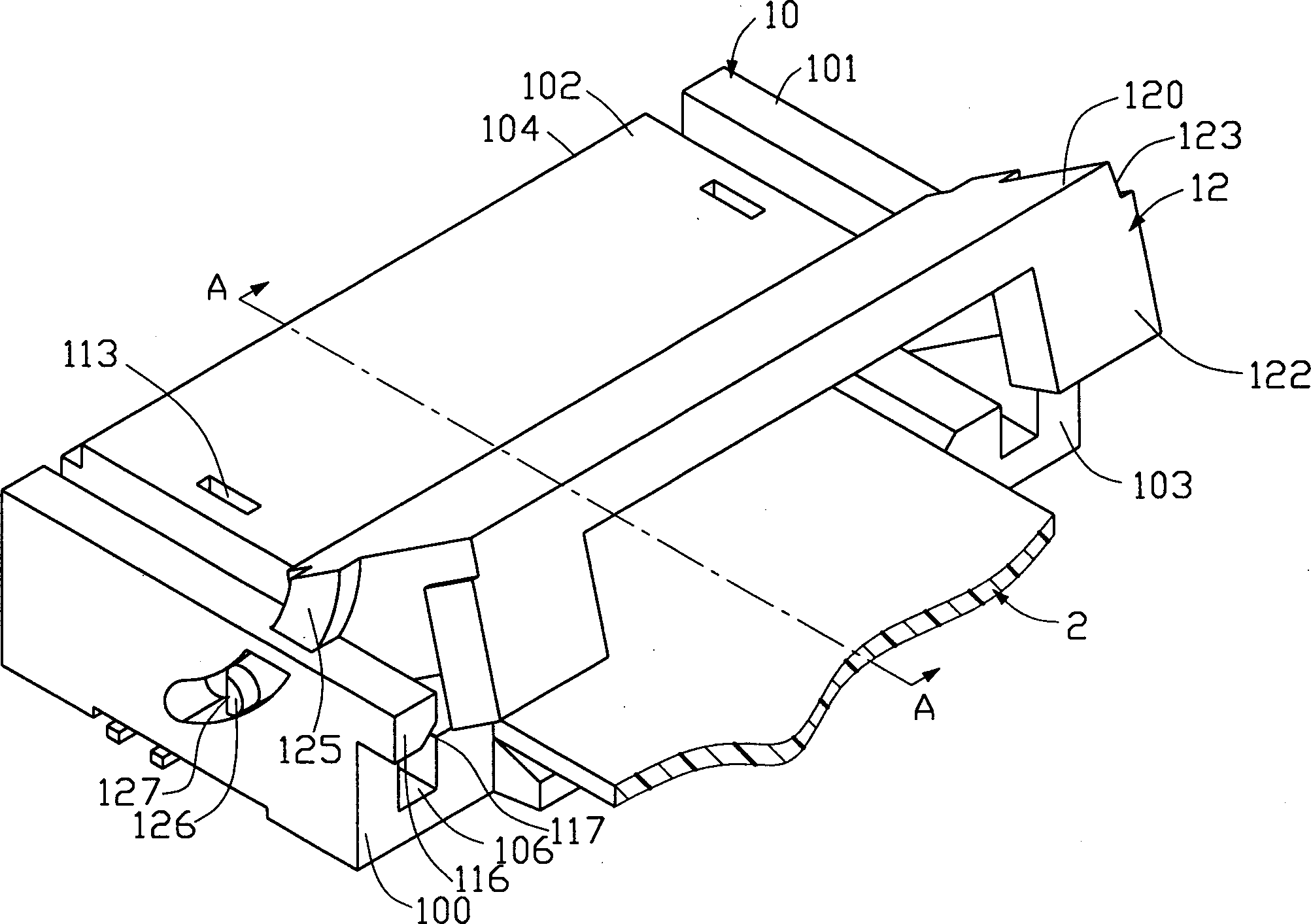

[0013] see figure 2 As shown, the electrical connector 1 of the present invention includes a base 10 , a cover 12 , conductive terminals 14 and a holding member 16 . The base 10 includes a base 100 , side walls 101 vertically disposed on both sides of the base 100 and a top plate 102 opposite to the base 100 . Wherein the base 100 is provided with a plurality of lower terminal receiving grooves 105 penetrating through the docking surface 103 and the connecting surface 104 of the base 10, and the two sides of the base 100 are symmetrically provided through the docking surface 103 and the connecting surface 104 of the base 10 for connecting with the cover 12 The groove 106 is engaged with each other, and an opening 107 ( Figure 7 shown). And the side wall 101 is provided with an arc-shaped inner chute 108 on the side adjacent to the docking surface 103 of the base 10 and connected to the groove 106, and the top of the inner chute 108 communicates with the upper surface of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com