Method for determining an angular error between a rotational angle value ascertained by means of an angle measuring system and a reference value

A technology for angle measurement and angle error, which is applied in the field of angle measurement systems, can solve expensive problems, achieve accurate verification and/or calibration, improve angle error calculation, and simplify calibration or verification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

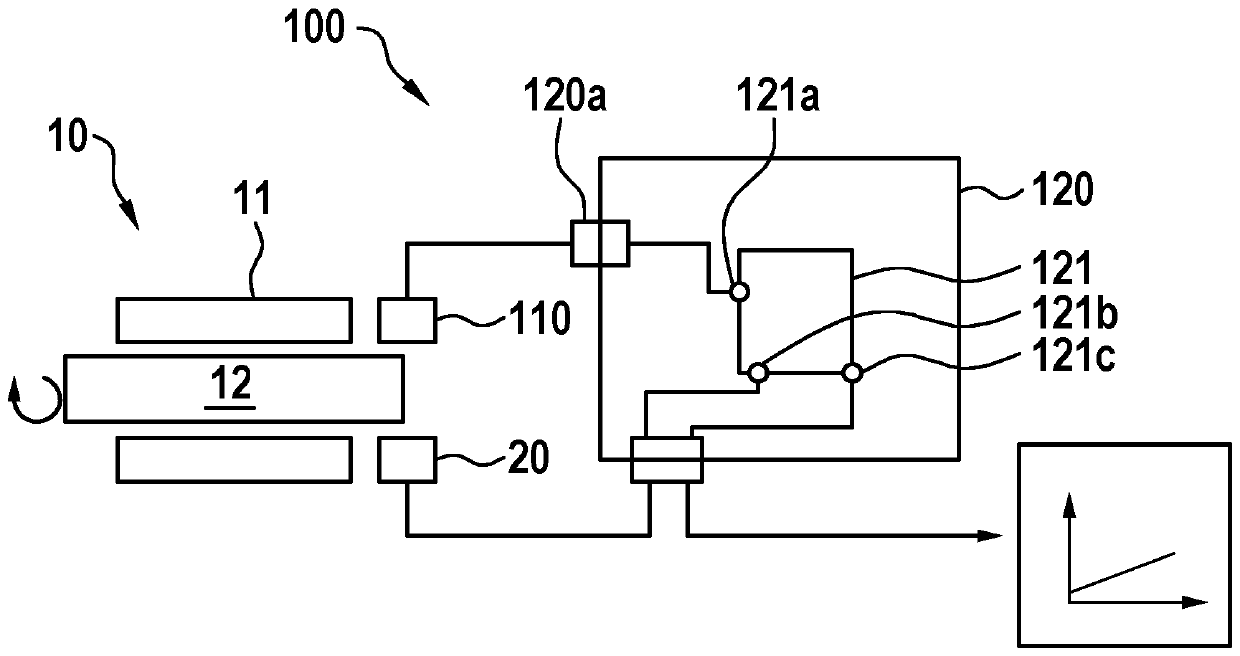

[0025] exist figure 1 A preferred embodiment of the angle measuring system 100 according to the invention is schematically shown in . Angle measuring system 100 has an angle of rotation sensor 110 and an evaluation unit 120 .

[0026] In particular, evaluation unit 120 has a microcontroller 121 which has an input 121 a for the rotation angle signal of rotation angle sensor 110 . The associated interface 120 a is formed on the evaluation unit 120 . Angle of rotation sensor 110 can be connected to interface 120a, for example, via a connecting cable.

[0027] Angle of rotation sensor 110 is arranged on electric machine 10 with stator 11 and rotor 12 for measuring the rotational movement of rotor 12 .

[0028] Evaluation unit 120 is designed to acquire a rotational angle value from the rotational angle signal of rotational angle sensor 110 .

[0029] If the evaluation unit is configured as a controller, for example, the rotational angle value can be used in normal mode in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com