A PVC insulating cable

An insulated cable, polyvinyl chloride technology, applied in insulated cables, insulated conductors, organic insulators, etc., can solve the problems of affecting the signal transmission of power core conductors, affecting the service life of the cable body, and not being able to protect the cable body. The effect of large-scale production and use, increasing signal interference ability and wide range of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

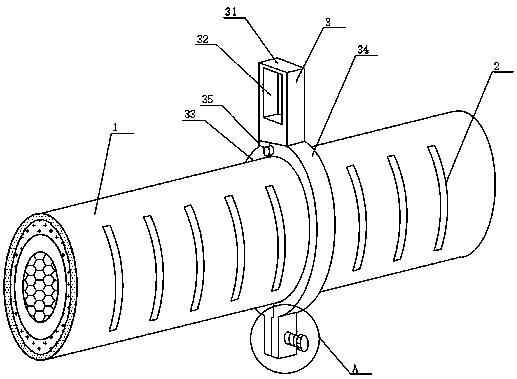

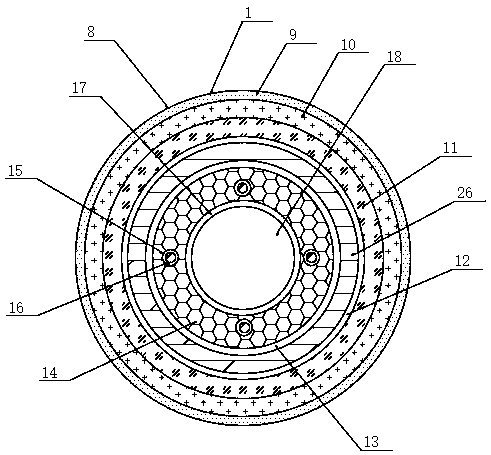

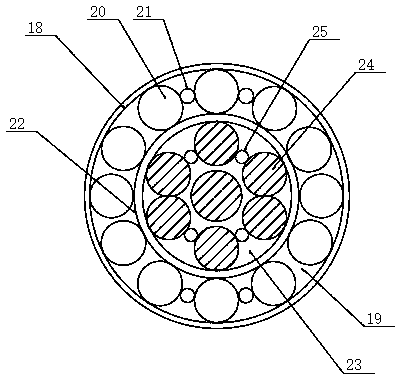

[0023] see Figure 1~5 , in an embodiment of the present invention, a polyvinyl chloride insulated cable includes a cable body 1 and a pulling mechanism 3, the surface of the cable body 1 is provided with anti-slip stripes 2, and the outside of the cable body 1 is equipped with a pulling mechanism 3, the cable body 1 A power line core conductor 24 is arranged near the center of the inside of the power line core conductor 24, and the power line core conductor 24 is surrounded by a first water blocking layer 22, and one side of the power line core conductor 24 is provided with The first water blocking yarn layer 25, and the surface of the first water blocking tape layer 22 is coated with a graphene layer, the thickness of the graphene layer is 0.2 nm to 0.4 nm, and the inside of the first water blocking tape layer 22 is filled with the first Filling layer 23, and the outside of the first water blocking belt layer 22 is wrapped with the second water blocking belt layer 18, the in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com