Hydraulic pump with long service life

A hydraulic pump with a long service life, which is applied to the components, pumps, and pump components of the pumping device for elastic fluids. Vibration and other problems to achieve the effect of improving stability and improving intuitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

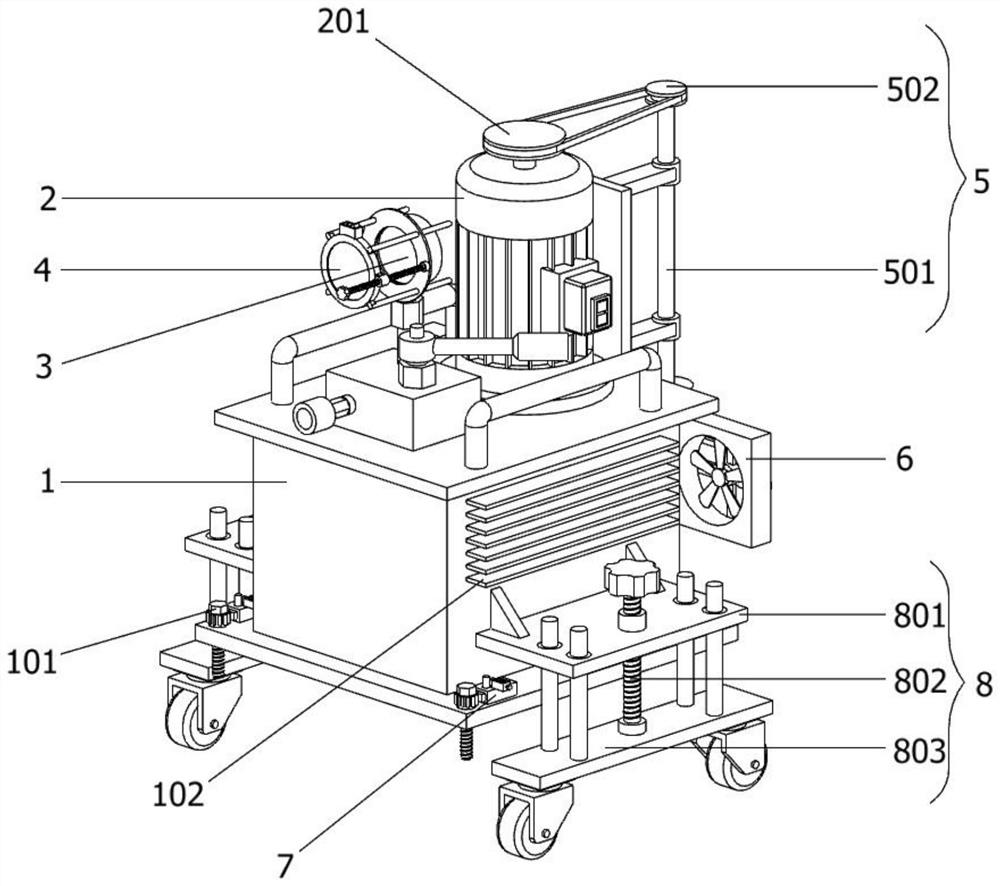

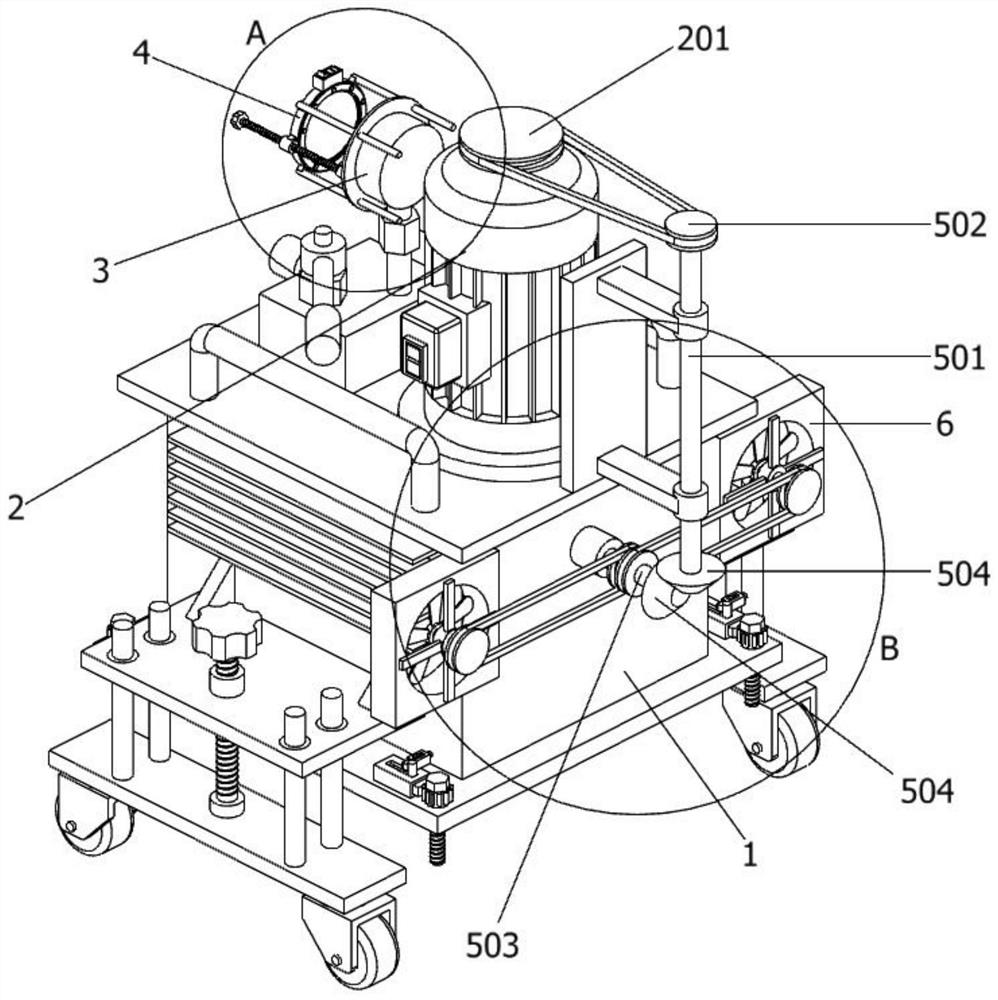

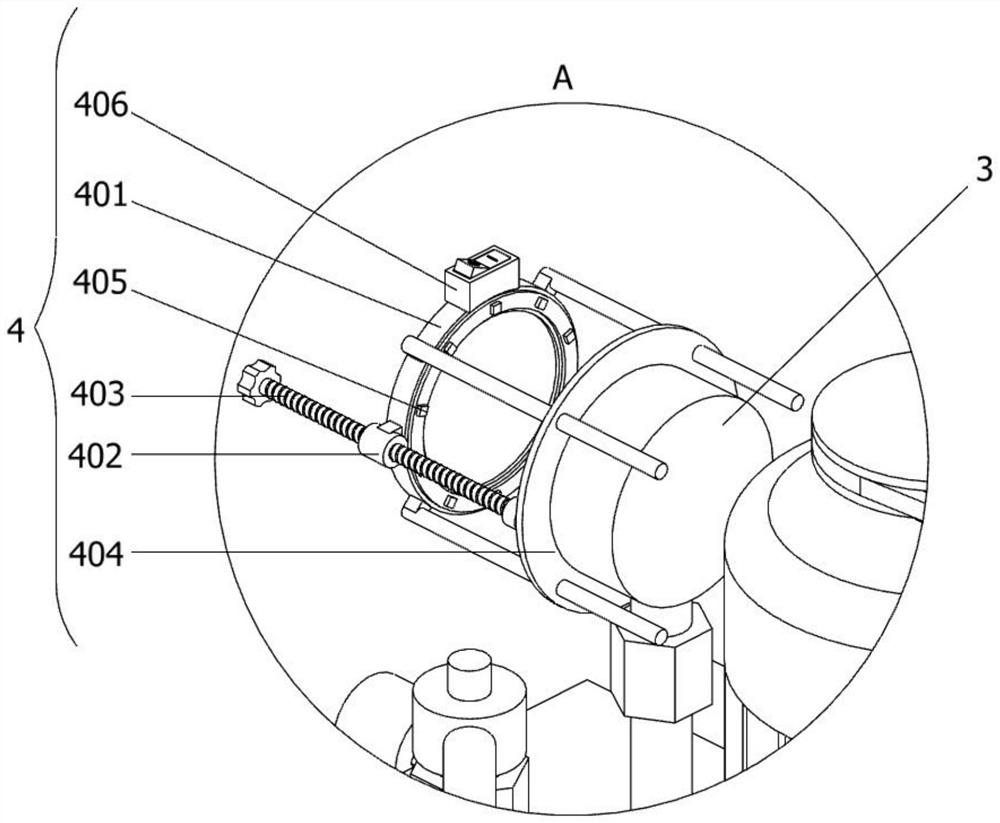

[0032] as attached figure 1 to attach Figure 7 Shown:

[0033] The present invention provides a hydraulic pump with a long service life, which includes: a main body 1, a double-headed drive motor 2 is installed on the rear side of the upper end of the main body 1, and the main body 1 includes fastening bolts 101, heat sinks 102 and fillet limit teeth 103 A fastening bolt 101 is connected through the four corners of the bottom plate of the main body 1, and the outer peripheral surface of the upper end of each fastening bolt 101 is arranged in a circular array with rounded limit teeth 103, and the upper left and right ends of the main body 1 All are uniformly provided with cooling fins 102, the fastening direction of the fastening bolts 101 is clockwise, and the rounded corners of the stop teeth 103 on the upper outer peripheral surface of the fastening bolts 101 are distributed in a clockwise direction; the upper part of the main body 1 The front side is provided with a pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com