Preparation method of high-density compact round aluminum conductor for cables

A technology of aluminum conductors and compactness, which is applied in the direction of cable/conductor manufacturing, circuits, electrical components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Further illustrate the present invention below in conjunction with accompanying drawing:

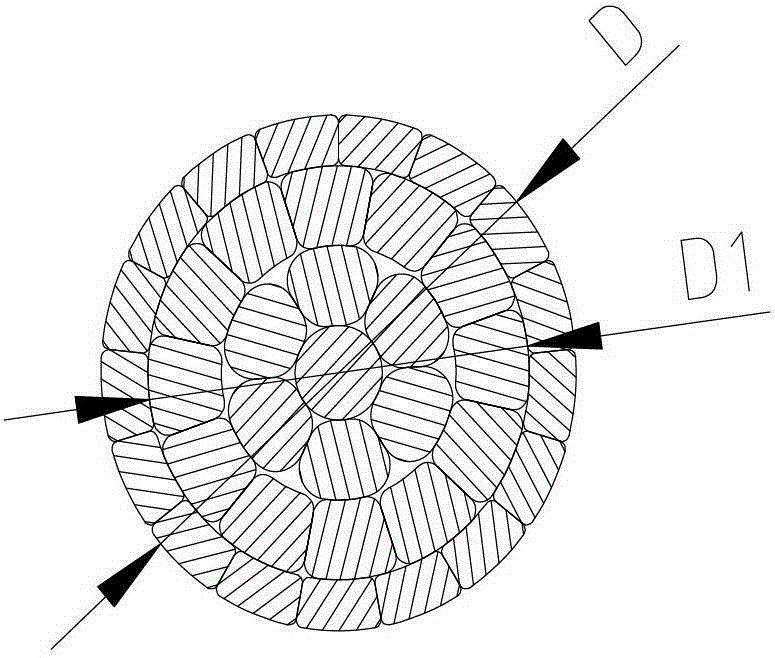

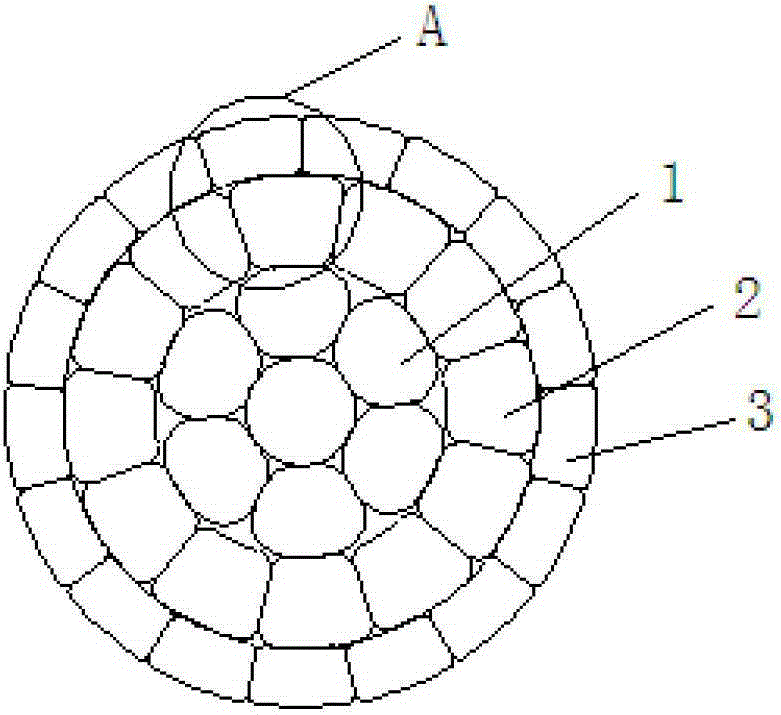

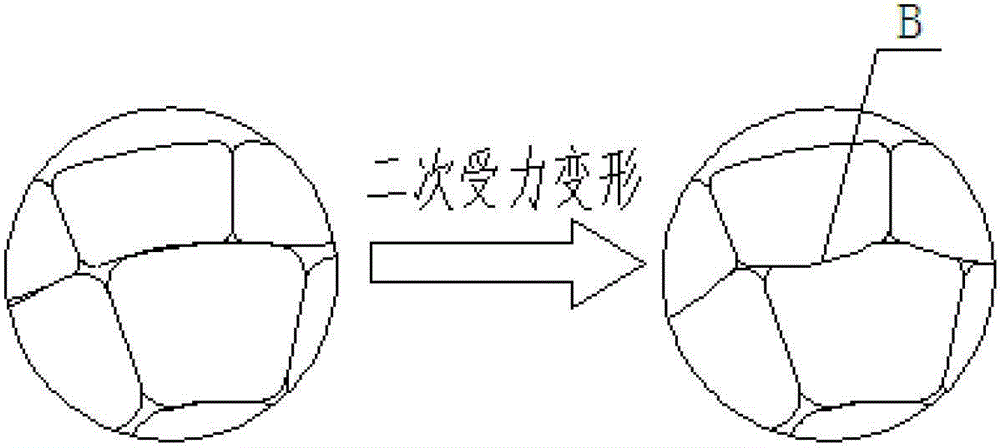

[0012] see figure 1 , The compaction coefficient of the conductor (also called the filling factor) = the sum of the cross-sectional area of each single wire / the circumscribed circle area of the twisted wire core. To expand, the compaction coefficient of a certain layer of the conductor = the cross-sectional area of each single wire in the layer The sum / area of the circle of the layer.

[0013] k 1 = π 4 × n 1 × d 2 D 2 - D 1 2

[0014] K1: Compression coefficient of the outermost layer of the conductor;

[0015] n1: the number of s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com