Two-way joint of protective net

A technology of protective nets and joints, which is applied to fixed grilles and other directions, can solve the problems of easy loosening of the frame, detachment of two adjacent frames, and easy softening, so as to improve connection reliability, reliable connection fastening, and enhance anti-theft effect of ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

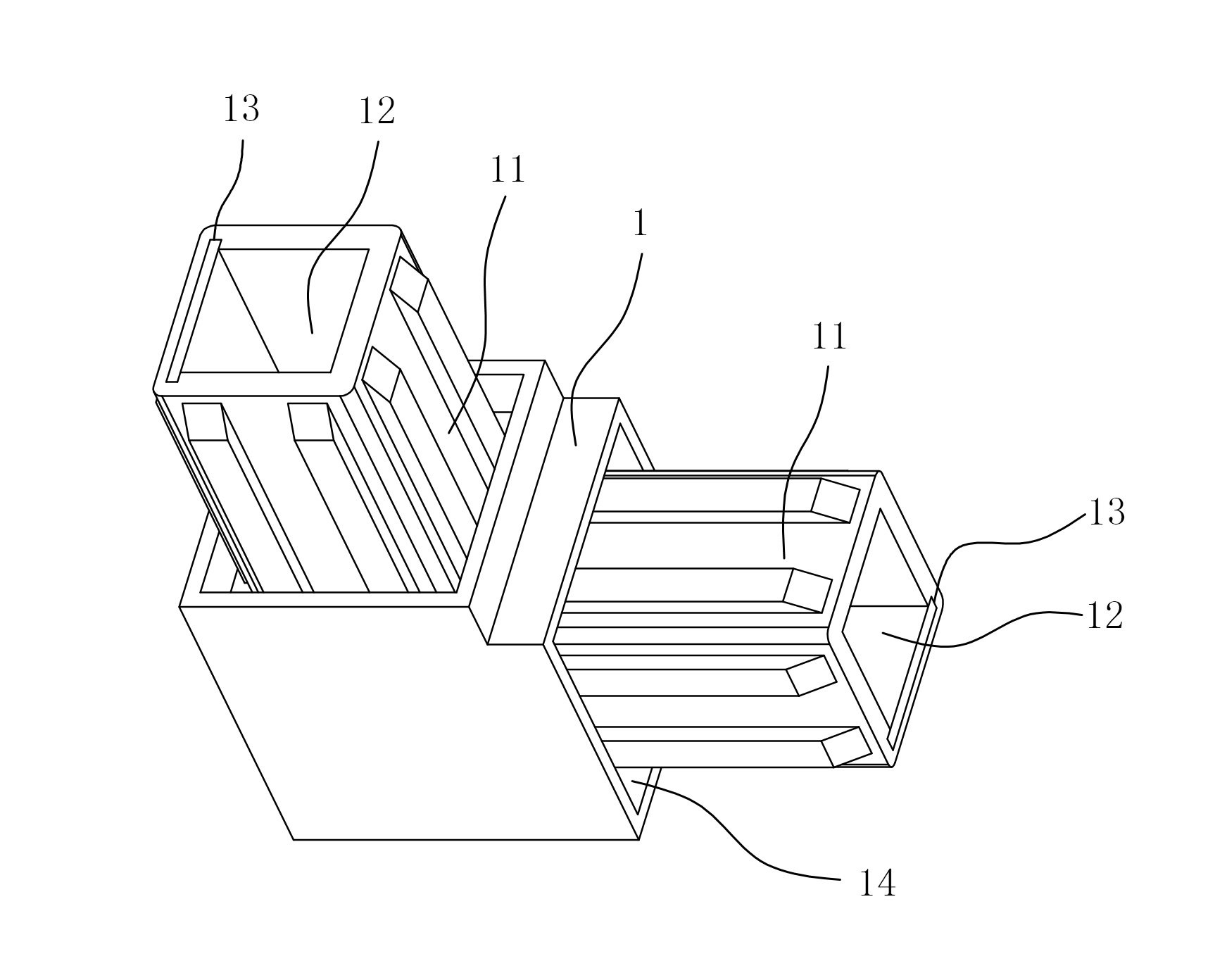

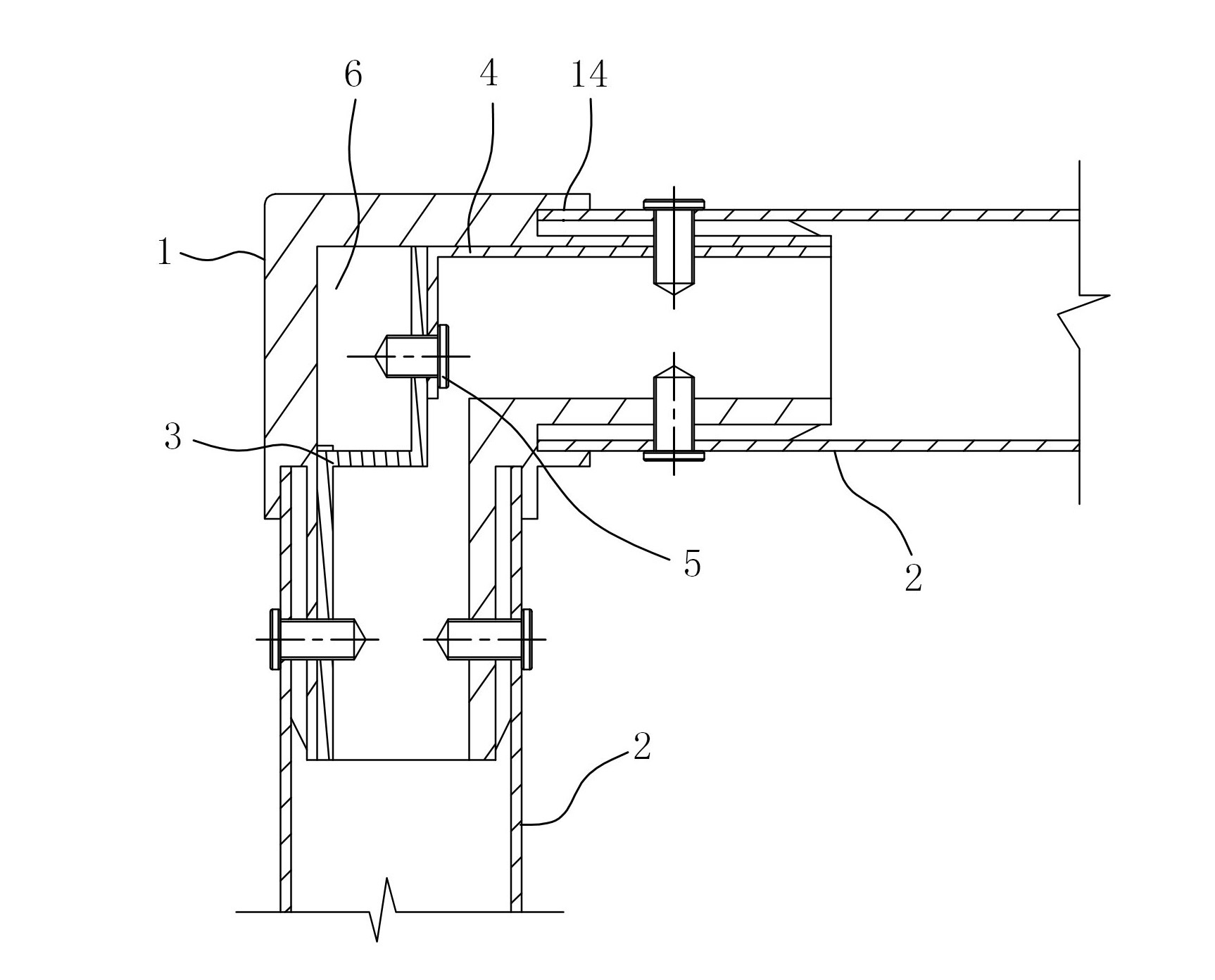

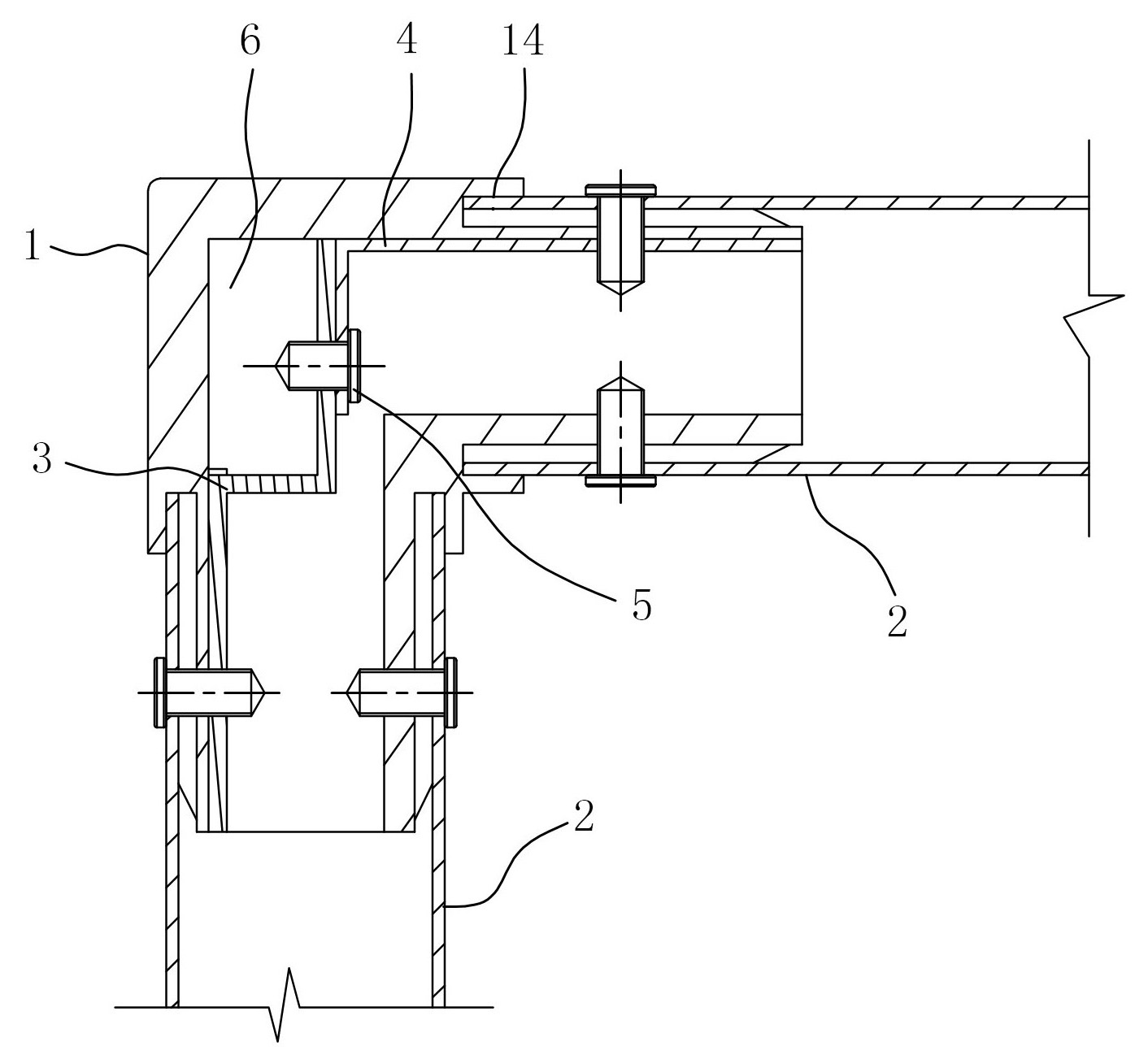

[0016] figure 1 and figure 2 An embodiment of a protective net two-way joint of the present invention is shown, the two-way joint includes a nylon two-way joint body 1, and the nylon two-way joint body 1 is provided with two sections of joints 11 for connecting the frame 2 of the protective net, The two joints 11 are respectively provided with an inner hole 12, and the two inner holes 12 are connected to each other. Each inner hole 12 is inserted into a metal plate, and the two metal plates are tightly connected. When the nylon part is aged, the frame 2 of the protective net is still passed through The connection of two metal plates can prevent the frame 2 of the adjacent protective net from detaching, greatly improving the connection reliability of the frame 2 of the protective net, so that the protective net still has a protective effect, and completely eliminates the safety hazards existing in the existing protective net; When the nylon part is softened and melted by fire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com