Wet-lime embedded once-molding construction process of cobblestone garden path and landscape floor

A construction technology, cobblestone technology, which is applied in the field of cobblestone garden road and wet ash mosaic construction technology on the landscape floor, can solve the problems such as difficult cleaning of the cobblestone surface, loose and falling pebbles, and slow construction progress, so as to improve the construction quality and stickiness The knot is firm and the effect of reducing the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

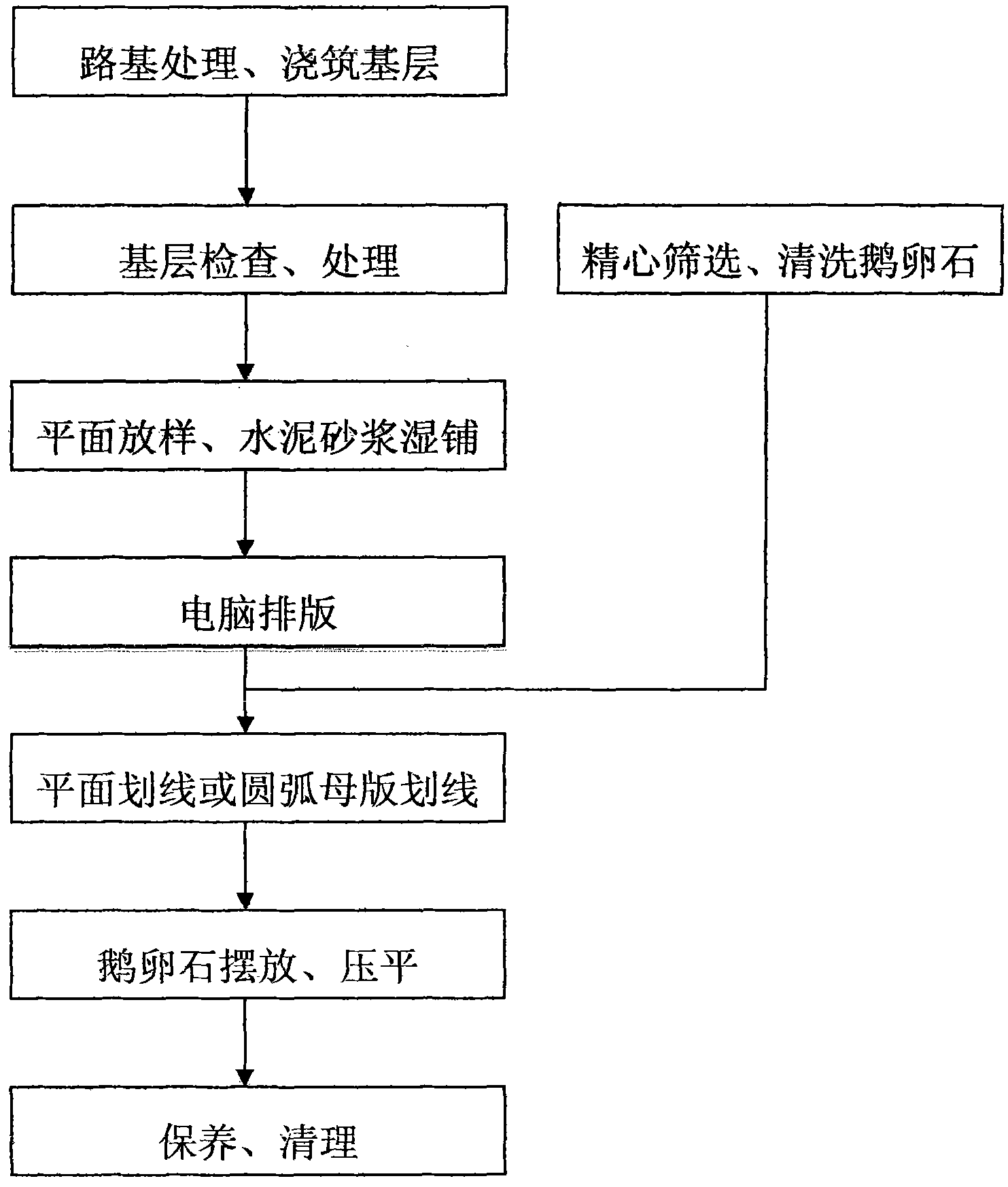

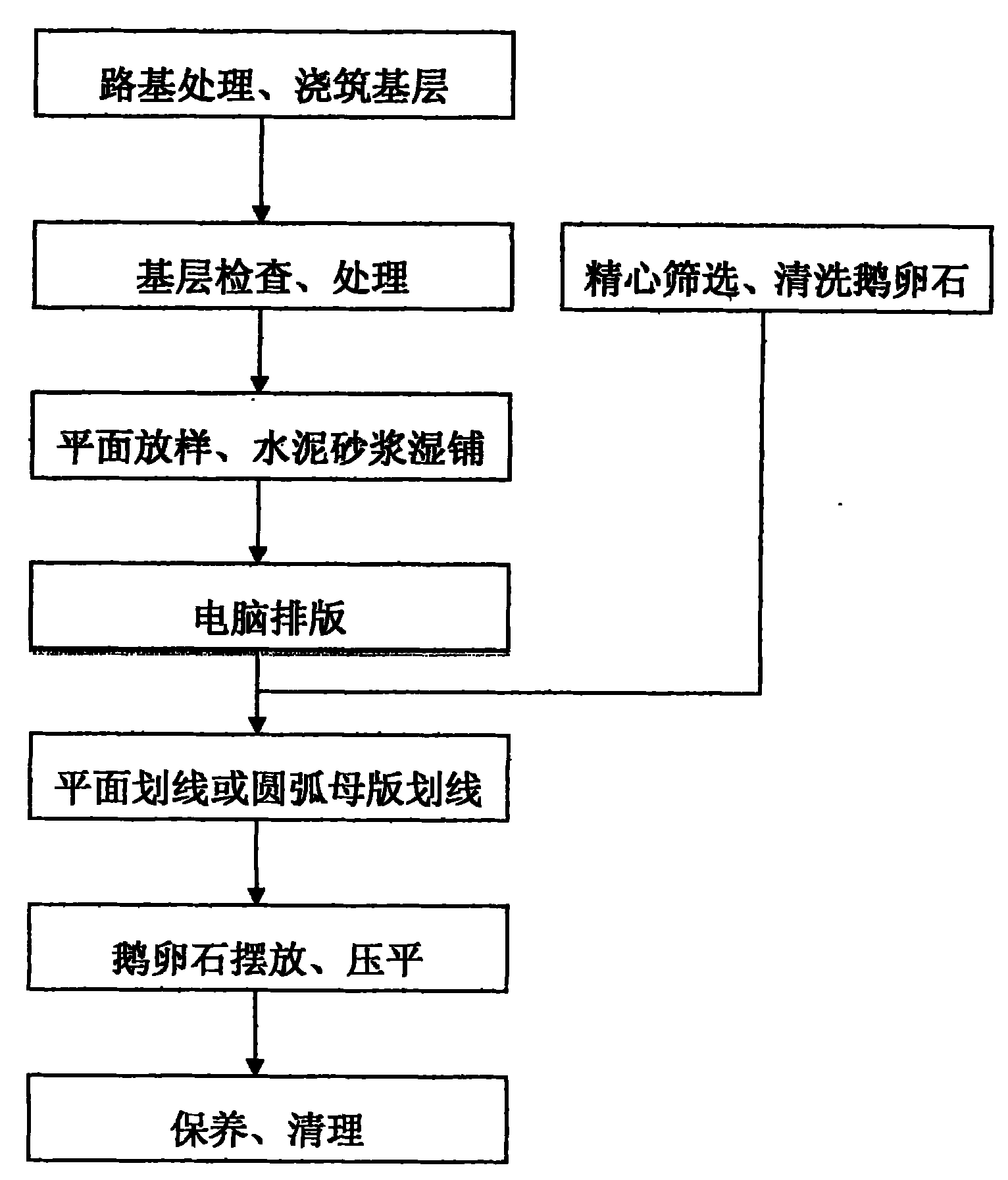

[0020] A cobblestone garden road and landscape ground wet ash mosaic one-time molding construction process of this embodiment includes the following steps:

[0021] First, carry out subgrade treatment and pouring of the base: according to the design requirements, carry out garden roads and landscape ground stakeouts, gray lines, and excavation (or filling). After the excavation (or filling) of the earthwork is completed, the base is cleaned and compacted, and then 60-80mm thick stones (preferably 40mm inch) are sprinkled on the excavated soft soil foundation (or filling) as a cushion layer, and the whole After leveling and sprinkling with water, pour 100mm of C15-20 concrete base on it. Set the drainage slope on the surface of the base layer, and set it at 1‰. Check and deal with the grassroots: comprehensively check the elevation, thickness, concrete strength, drainage slope, and surface smoothness of the concrete at the grassroots level. Repair unqualified parts. Then cle...

Embodiment 2

[0028] A cobblestone garden road and landscape ground wet ash mosaic one-time molding construction process of this embodiment includes the following steps:

[0029] First, carry out subgrade treatment and pouring of the base: according to the design requirements, carry out garden roads and landscape ground stakeouts, gray lines, and excavation (or filling). After the excavation (or filling) of the earthwork is completed, the base is cleaned and compacted, and then 60-80mm thick stones (preferably 40mm inch) are sprinkled on the excavated soft soil foundation (or filling) as a cushion layer, and the whole After leveling and sprinkling with water, pour 120mm of C15-20 concrete base on it. Set the drainage slope on the surface of the base course, and set it at 2‰. Check and deal with the grassroots: comprehensively check the elevation, thickness, concrete strength, drainage slope, and surface smoothness of the concrete at the grassroots level. Repair unqualified parts. Then cl...

Embodiment 3

[0036] A cobblestone garden road and landscape ground wet ash mosaic one-time molding construction process of this embodiment includes the following steps:

[0037] First, carry out subgrade treatment and pouring of the base: according to the design requirements, carry out garden roads and landscape ground stakeouts, gray lines, and excavation (or filling). After the excavation (or filling) of the earthwork is completed, the base shall be cleaned and compacted, and then 60-80mm thick stones (preferably 40mm inch) shall be sprinkled on the excavated soft soil foundation (or filling) as a cushion layer. After leveling and sprinkling water to make it wet, pour 110mm C15-20 concrete base on it. Set the drainage slope on the surface of the base course, and set it at 1.5‰. Check and deal with the grassroots: comprehensively check the elevation, thickness, concrete strength, drainage slope, and surface smoothness of the concrete at the grassroots level. Repair unqualified parts. T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com