Subsoiling and smashing and ridging machine

A powder ridge machine and powder ridge technology, applied in the direction of harvesters, crop processors, agricultural machinery and implements, etc., can solve problems such as damage to the driving mechanism, high bearing seat height, and manufacturing difficulties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

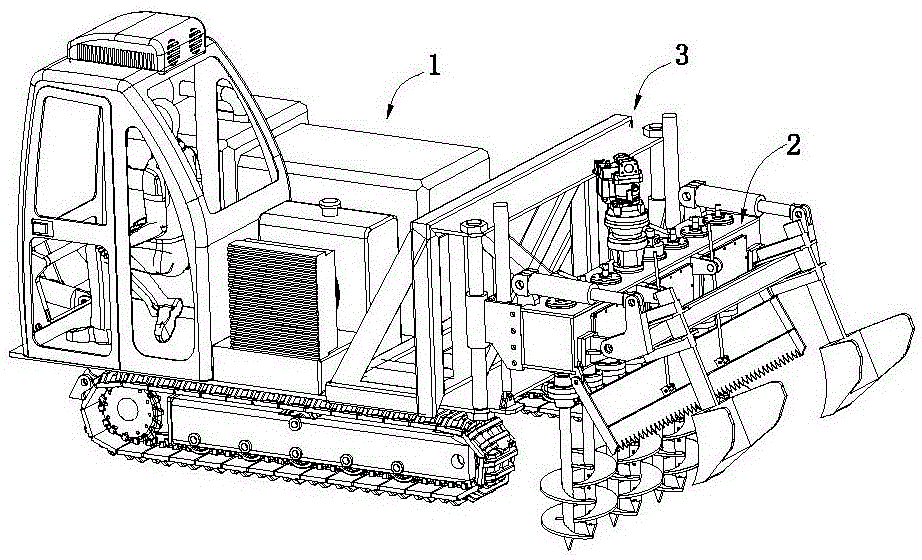

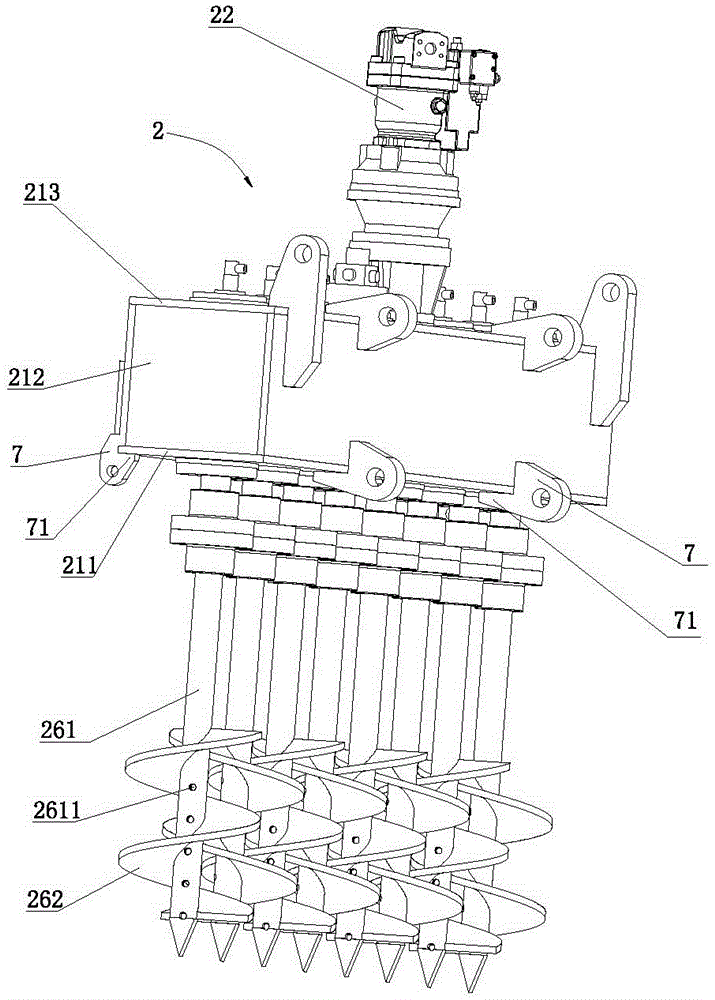

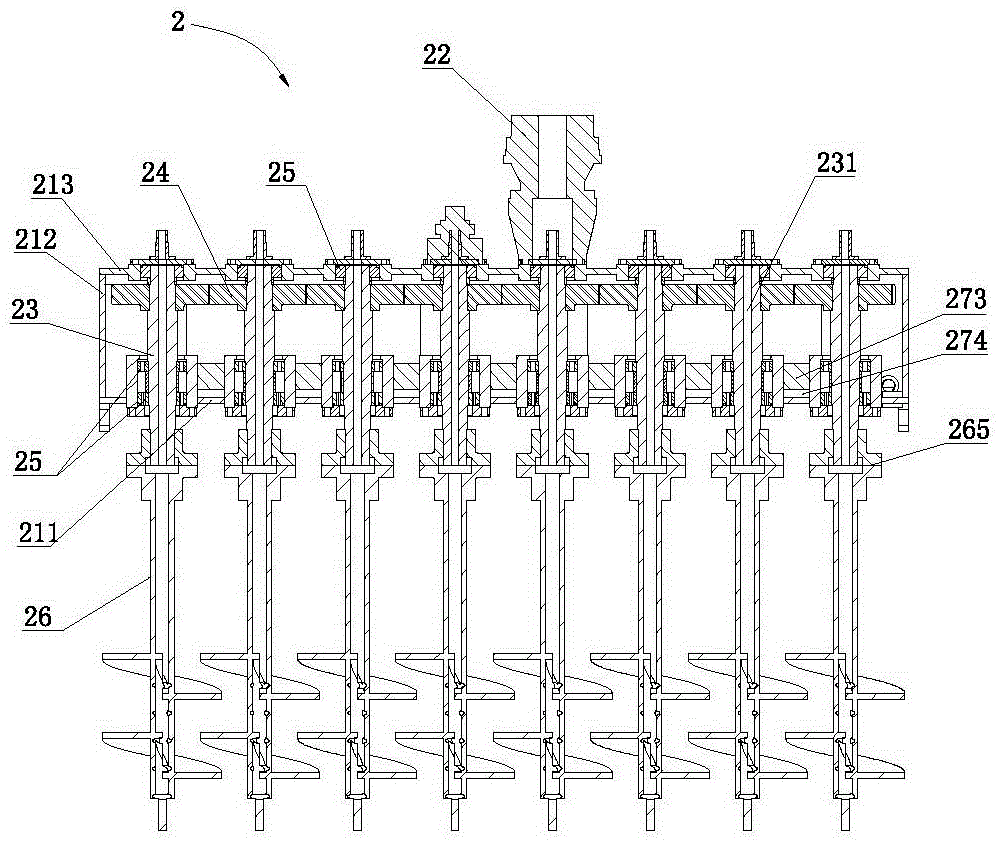

[0057] Such as figure 1 and figure 2 As shown, the loose tillage powder ridge machine includes a body 1, a powder ridge device 2, and a connecting device 32.

[0058] Such as figure 2 As shown, the body 1 includes a traveling mechanism 11 , a frame 12 , a diesel engine assembly 13 , a hydraulic oil tank 14 , a cooler 15 and a cab 16 .

[0059] Such as Figure 3 to Figure 8 As shown, the running mechanism 11 includes two opposite crawler belt assemblies, and the crawler belt assembly includes a wheel frame 111, a driving wheel 112, a driven wheel 113, a lower guide wheel 114, an upper guide wheel 115, a crawler belt 116 and a travel drive.

[0060] Such as Figure 7 and Figure 8 As shown, the wheel frame 111 includes a wheel frame body 1111 and a wheel frame connecting ear 1112 . The wheel frame connecting ear 1112 is connected to the front end of the wheel frame body 1111 . The rear end of the wheel frame body 1111 is provided with a driven wheel accommodating groove...

Embodiment 2

[0141] Compared with Embodiment 1, this embodiment has the same structure except for the connecting device. In this example, if Figure 22 to Figure 24 As shown, the connecting device 3 includes two linkage mechanisms and a connecting rod 310a connected to the two linkage mechanisms. The connecting rod mechanism includes a connecting rod seat 30a, a first connecting rod 31a, a second connecting rod 32a, a third connecting rod 33a, a fourth connecting rod 34a and a driving cylinder 35a. The connecting rod base 30a is fixed on the supporting platform; the lower end of the first connecting rod 31a is hinged on the rear end of the connecting rod base 30a, and one end of the second connecting rod 32a is hinged on the position below the middle part of the first connecting rod 31a, and the second connecting rod The other end of 32a is hinged on the first connecting ear 29; one end of the third connecting rod 33a is hinged on the upper end of the first connecting rod 31a, the other e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com