Temperature-controllable rock uniaxial compression sound emission test device and temperature-controllable rock uniaxial compression sound emission test method

A uniaxial compression and test device technology, which is applied in the direction of applying stable tension/pressure to test the strength of materials, can solve the problems of missing important information of acoustic emission, failure to ensure that the sensor can meet the requirements, etc., and achieve good practical significance and application value, reduce disassembly steps, and reduce missing effects

Inactive Publication Date: 2015-09-16

UNIV OF SCI & TECH BEIJING

View PDF12 Cites 25 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Experiments have shown that the acoustic emission signals released by rocks in different stress stages have different combination modes. If only a single detection frequency band is used, important information of acoustic emission may be missed

[0004] In the international rock mechanics test standard, the suggested requirement for the rock sample is a standard cylinder. Usually, when the rock uniaxial compression acoustic emission detection test is carried out in the laboratory, the placement method of the acoustic emission sensor

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

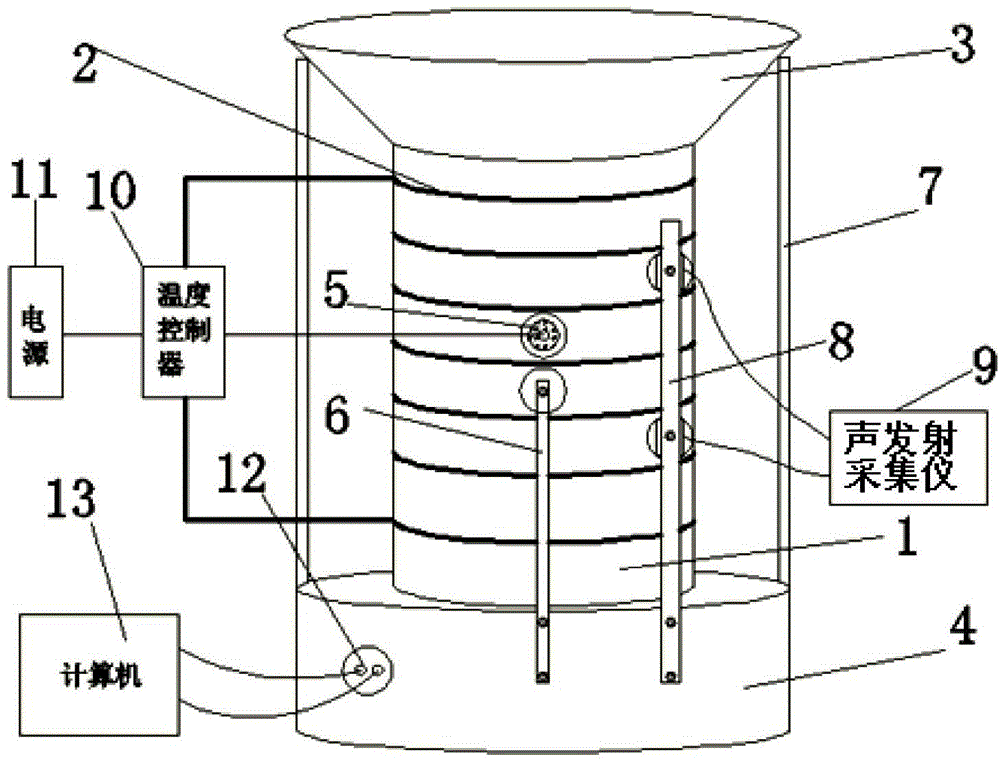

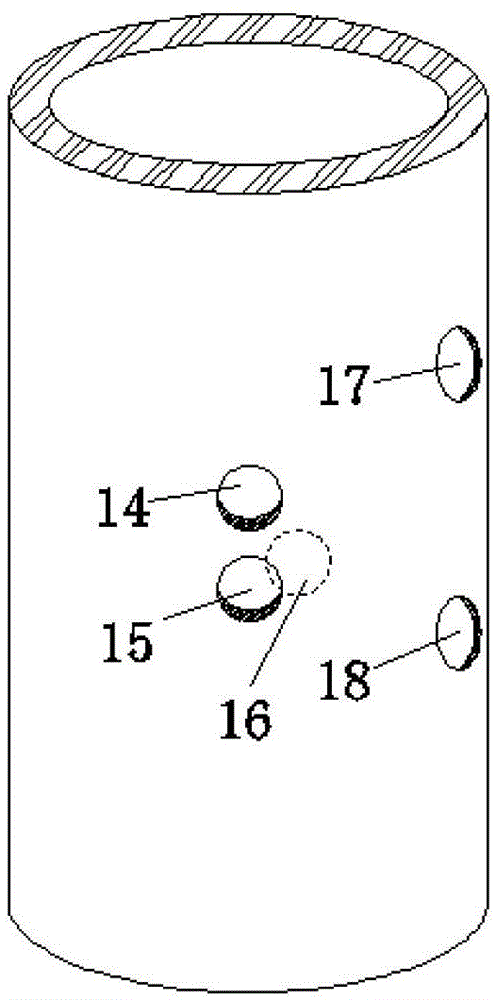

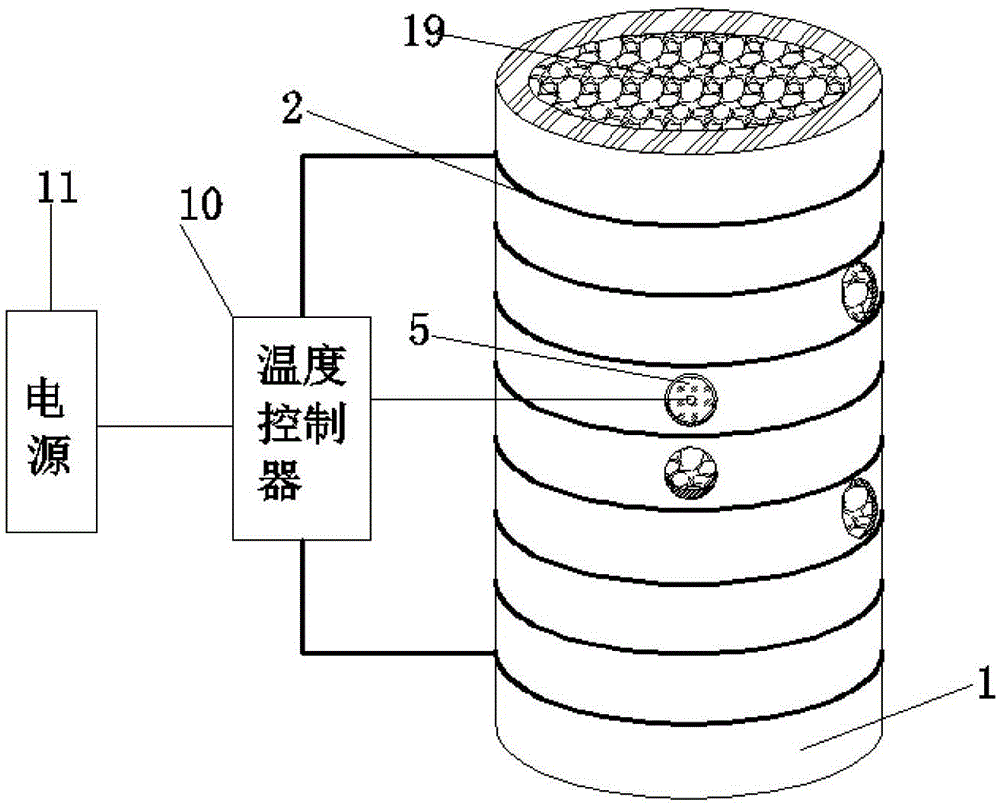

The invention discloses a temperature-controllable rock uniaxial compression sound emission test device and a temperature-controllable rock uniaxial compression sound emission test method. The test device comprises a loading system, a heating system, a temperature control system, a strain system and a sound emission system, wherein the heating system, the temperature control system, the strain system and the sound emission system are all arranged on the loading system. According to the test method, a rock sample is arranged inside a soft shell, heating resistance wires are distributed around the outside of the shell, and a temperature sensor, radial and axial strain gauges and a sound emission sensor are arranged, so that the uniaxial compression multi-channel sound emission detection test can be implemented. According to the test device and the test method, the sound emission detection of the rock sample under different temperature environment influences can be simulated. The test device has a simple structure, is convenient to operate and can be used for simulating the sound emission detection demands of rock materials under different temperature environments indoors.

Description

technical field [0001] The invention relates to a temperature-controllable rock uniaxial compression acoustic emission test device and a test method, which are mainly suitable for simulating rock uniaxial compression multi-channel acoustic emission detection tests under different temperature environments in a laboratory. Background technique [0002] Temperature is an important factor affecting the physical and mechanical properties of rocks. With the rapid development of the national economy, deep rock underground engineering will increase day by day. However, the deeper into the deep engineering, the rock will be affected by the more complex temperature environment, and its physical and mechanical properties will also undergo significant changes. Therefore, it is of great significance to study the influence of temperature on the physical and mechanical properties of rocks. At present, in the uniaxial compression test of rocks in the laboratory, for the research on the ph...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01N3/08

Inventor 纪洪广曾鹏由爽高宇蒋华唐文娣刘翔宇曹杨孙利辉

Owner UNIV OF SCI & TECH BEIJING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com