Online degassing device for ion chromatograph

An ion chromatograph and degassing device technology, applied in the field of online degassing devices, can solve problems such as changes, affecting detection sensitivity, and secondary generation of bubbles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

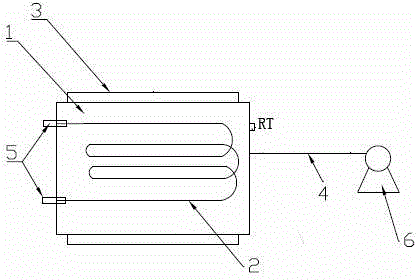

[0016] In order to clearly illustrate the technical features of the solution, the solution will be described below through a specific implementation mode combined with the accompanying drawings.

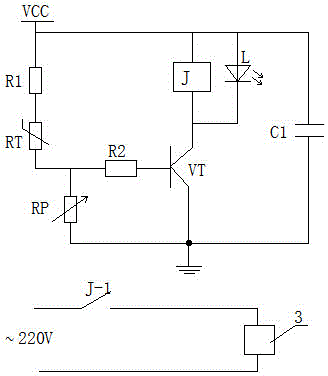

[0017] As can be seen from the accompanying drawings, an online degassing device for an ion chromatograph of the present program includes a housing 1, the housing 1 is a metal housing, and the permeation tube 2 arranged in the housing 1, the permeation tube is Amorphous fluororesin degassing tube. Vacuum pump 6, the vacuum pump 6 communicates with the inside of the housing 1 through the pipeline 4, the housing 1 is provided with an electric heater 3, and the housing 1 is also provided with an ion chromatograph flow joint 5, an ion chromatograph flow joint 5 Connected with the permeation tube 2, the shell 1 is provided with a thermistor RT, one end of the thermistor RT is connected to VCC through the first resistor R1, the other end of the thermistor RT is grounded through the sliding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com