LED chip waxing robot temperature control method

A technology of LED chip and temperature control system, applied in the direction of speed/acceleration control, non-electric variable control, control/regulation system, etc., to achieve the effect of easy control of heating current, high cooling efficiency and short cooling circuit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

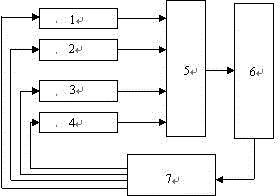

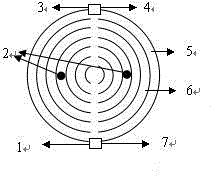

Method used

Image

Examples

Embodiment Construction

[0015] Referring to the accompanying drawings of the description, the control method of the present invention will be described as follows to control the temperature of the LED chip production process. The specific operations are: 1) Planning the temperature cooling curve. The corresponding relationship between the temperature change of the wax used and the state change of the wax is measured through experiments, and the ideal temperature change curve is fitted by a segmented linear regression method as a planning curve.

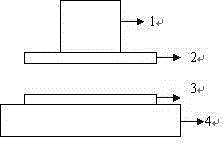

[0016] 2) The temperature control plate is heated. When the temperature control workbench of the LED chip waxing robot is not working, the temperature is normal temperature. When the temperature control workbench needs to work, put the paste plate on it, and the temperature control plate will start heating and the temperature will rise to 105°C.

[0017] 3) Then spray wax, patch, pressurize, and start the cooling system.

[0018] 4) Cool down and cool down...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com