Measuring device of tubular part inner wall processing stress and measuring method thereof

A technology for processing stress and measuring device, applied in the direction of measuring device, measuring force, instrument, etc., can solve the problems of large error in measurement results, expensive X-ray stress meter, error, etc., and achieves simple device, reliable result data, and cost. low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

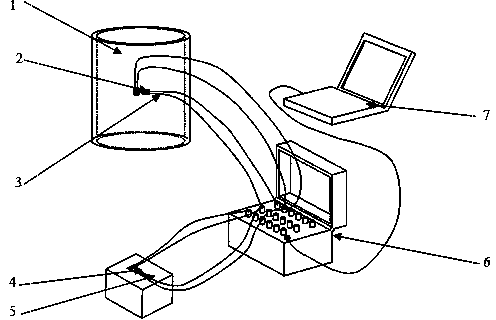

[0020] Below in conjunction with accompanying drawing, technical scheme of the present invention is described in detail:

[0021] like figure 1 As shown in the figure, a measuring device for the machining stress of the inner wall of a tubular part includes a tubular part 1 to be measured, and an axial strain gauge 2, a tangential strain gage 3, an axial strain gauge 2, The tangential strain gauges 3 are respectively connected to the strain gauges 6 by wires, the axial compensation gauges 4 and the tangential compensation gauges 5 are respectively connected to the strain gauges 6 by wires, and the strain gauges 6 are connected to the PC by wires.

[0022] The axial length L and the outer diameter b of the measured tubular part 1 of the present invention satisfy L≥1.11b.

[0023] Silica gel is coated between the axial strain gauge 2, the tangential strain gauge 3 and the measured tubular part 1 of the present invention. To protect the strain gauge from the external environment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com