Asphalt mixture dynamic modulus testing method

A technology of asphalt mixture and dynamic modulus, which is applied in the direction of applying repeated force/pulsation force to test the strength of materials, etc., can solve the problems of complicated operation, unfavorable promotion and use, and high requirements for SPT dynamic modulus test equipment, so as to achieve simple operation, Easy to popularize and use, and the effect of simple test equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0016] Asphalt mixture dynamic modulus testing method provided by the invention comprises the steps:

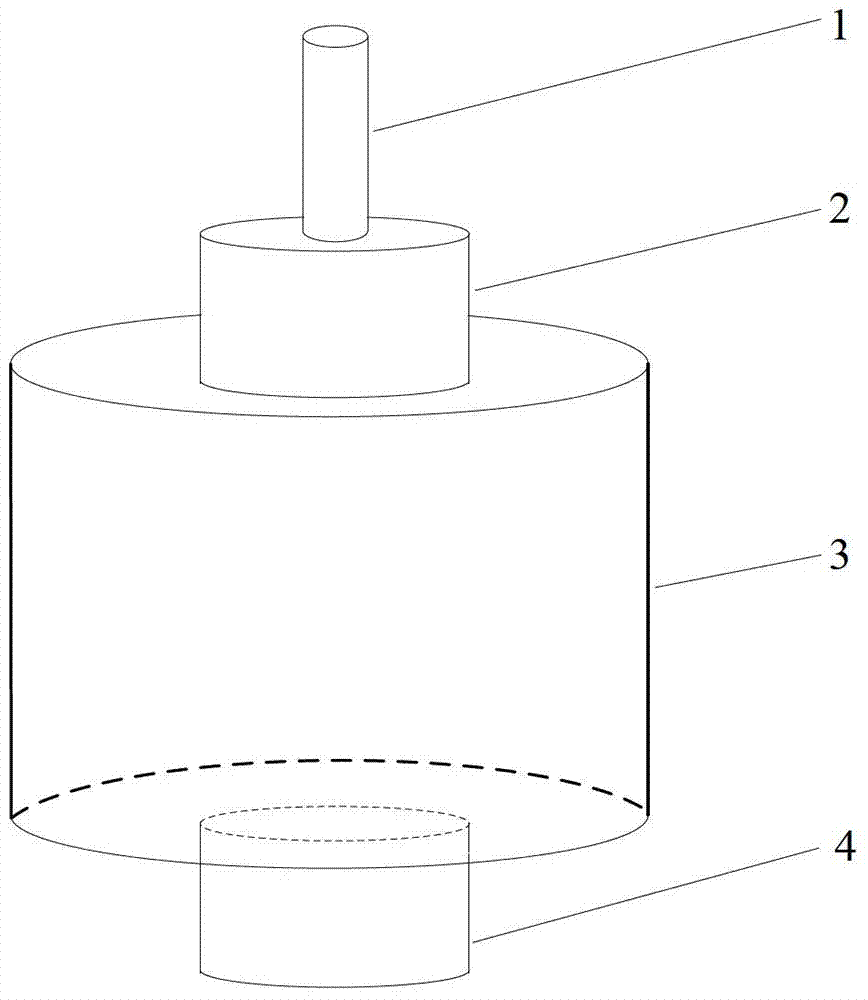

[0017] Step 1: Use an asphalt mixture gyratory compactor to form an asphalt mixture specimen, and obtain a fixed-sized asphalt mixture cylinder specimen by cutting;

[0018] Step 2: Prepare two indenters, put the test piece and the two indenters into the environmental chamber at the target temperature for 5 hours;

[0019] Step 3: Take out the two indenters and the test piece, and place the two indenters in the middle of the two ends of the cylindrical test piece; apply sinusoidal axial compressive stress to the test piece at different frequencies at the specified test temperature;

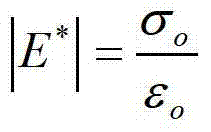

[0020] Step 4: During the loading process, measure the applied stress and the generated axial strain at the corresponding time, and the dynamic modulus is the ratio of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com