Excitation method of vibrating wire sensor

A vibrating wire sensor and excitation technology, which is applied in the field of sensor measurement, can solve the problems of unfavorable picking and processing of vibrating wire vibration signals, short vibration duration, and attenuation of vibration amplitude, so as to prolong the vibration duration, shorten the detection time, large amplitude effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

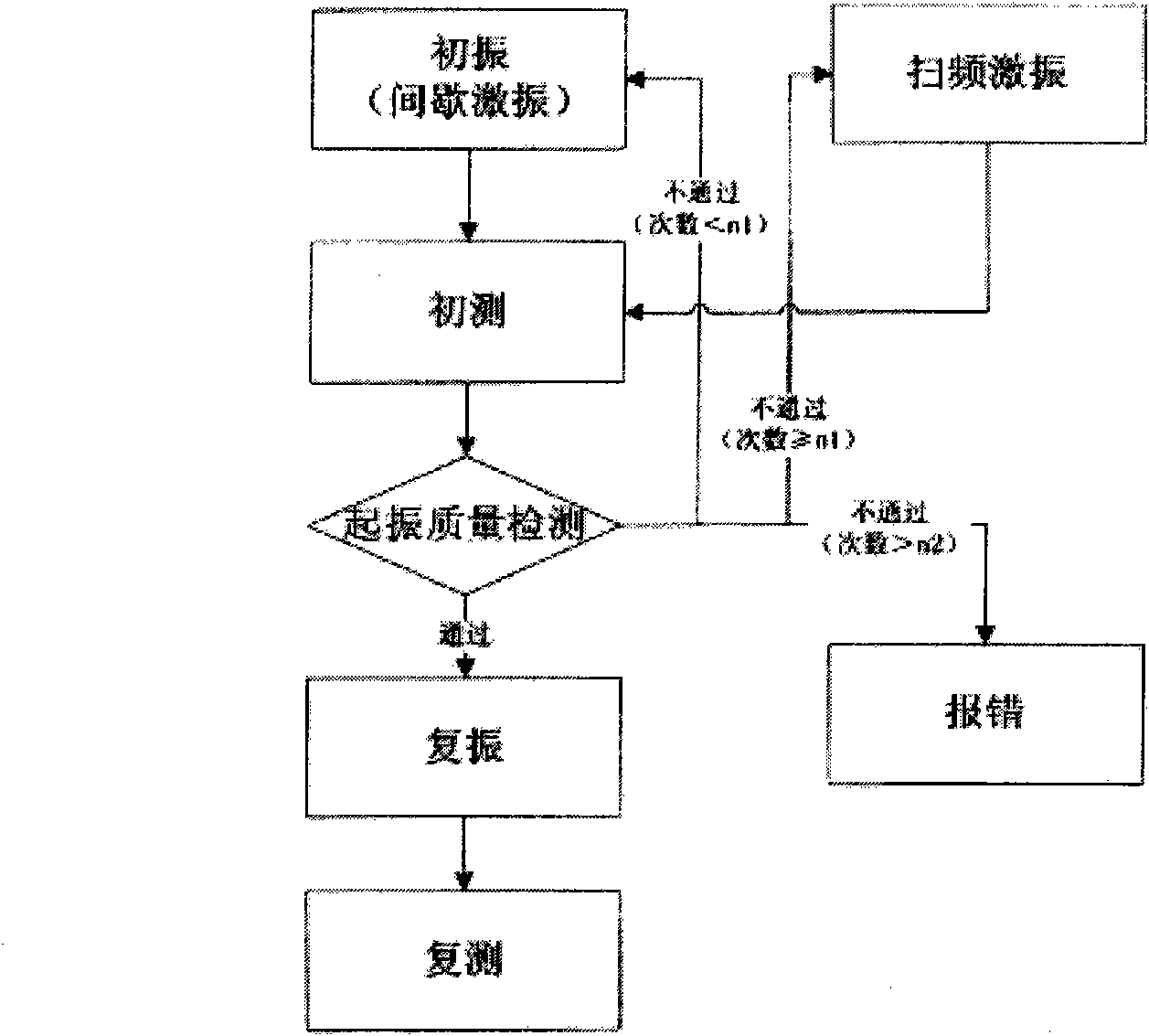

[0025] The specific embodiment of the present invention is as figure 1 Shown:

[0026] The first step, initial vibration: use the existing intermittent excitation method to excite the excitation coil of the vibrating wire sensor once;

[0027] The second step, preliminary test: process the signal of the pickup coil and measure the signal frequency. Since the intermittent excitation method will cause the vibration amplitude to be small and the vibration duration to be short, only the signal with the best quality at the initial stage of vibration is used for short-term measurement in the initial measurement process to obtain the initial measurement value f1 of the resonance frequency. Since the number of signal cycles measured during the initial measurement is small, the signal amplitude is small, and the measurement accuracy is low, the initial measurement value f1 of the frequency obtained is not accurate.

[0028] The third step, inspection: record the period (T1, T2, . As...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com