Solid wood composite floor fit for geothermal heat and manufacturing method thereof

A technology of solid wood composite flooring and manufacturing methods, applied in the direction of manufacturing tools, building structures, wood processing appliances, etc., can solve problems such as unfavorable heat transfer, achieve the effects of saving hardwood resources, broadening application fields, and good biological durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The double-layer structure solid wood composite floor suitable for geothermal heating, its manufacturing method is divided into 1, the preparation of the solid wood composite floor surface board; 2, the preparation of the composite floor base material; 3, the preparation of the composite floor.

[0023] One of them, the preparation of the solid wood composite floor surface board: dry the surface board blank with a width of 90 mm and a thickness of 25 mm to make its moisture content 12%, and divide it into 6 mm thick surface board products with a frame saw or a splitting machine.

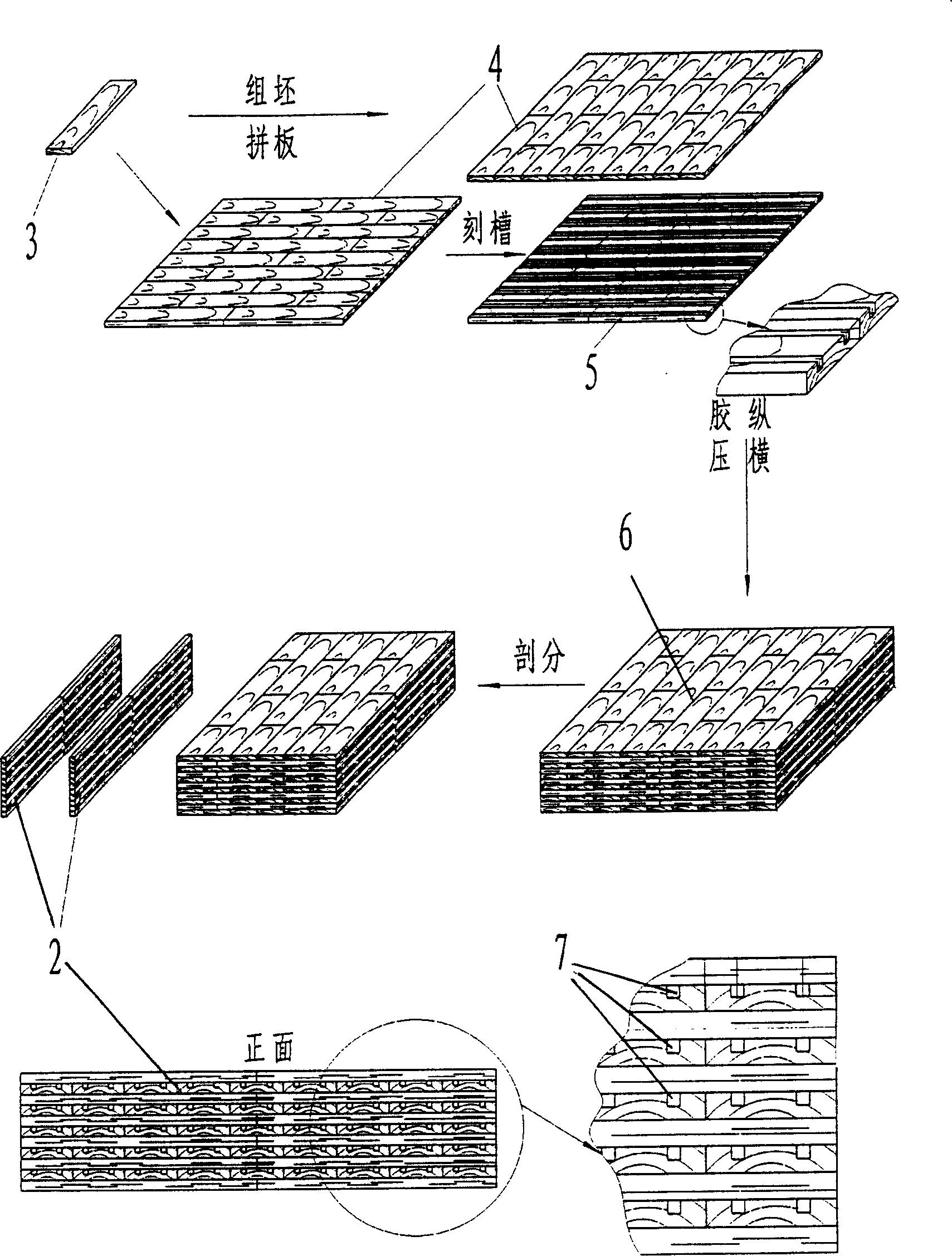

[0024] 2. Preparation of composite floor base material: a composite structure spliced with fast-growing wood and solid wood is adopted, specifically carbonizing the fast-growing wood carbonized wood blank, and the treatment temperature is 240° C.; mechanically processing the carbonized blank to obtain a thin plate 3, Coat the side of sheet 3 with urea-formaldehyde resin glue, the amount of gl...

Embodiment 2

[0027] The double-layer structure solid wood composite floor suitable for geothermal heating, its manufacturing method is divided into 1, the preparation of the solid wood composite floor surface board; 2, the preparation of the composite floor base material; 3, the preparation of the composite floor.

[0028] One of them, the preparation of solid wood composite floor boards: dry the board blanks with a certain size such as 200mm wide and 150mm thick to make their moisture content 6%, and split them into 3mm thick finished boards with a frame saw or splitter.

[0029] 2. Preparation of composite floor base material: a composite structure spliced with fast-growing wood and solid wood is adopted, specifically carbonizing the fast-growing wood carbonized wood blank, and the treatment temperature is 160° C.; mechanically processing the carbonized blank to obtain a thin plate 3, Apply urea-formaldehyde resin glue to the side of the thin plate 3, and the amount of glue applied is 3...

Embodiment 3

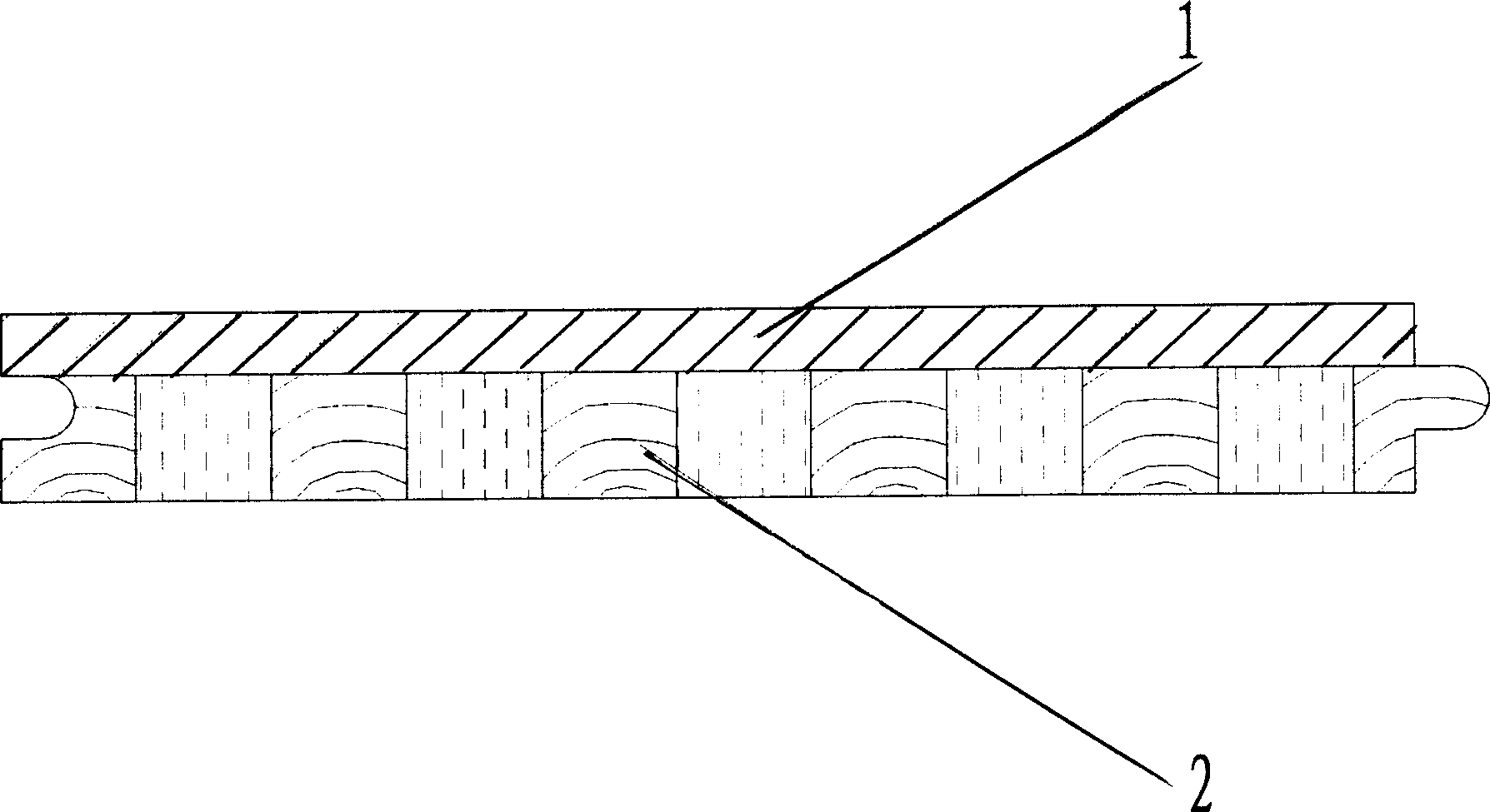

[0032] The three-layer structure solid wood composite floor suitable for geothermal heating is manufactured by pasting a layer of rotary-cut wood veneer or thin wood veneer with a thickness of 2 to 3 mm on the bottom of the carbonized wood base plate 2 on the basis of the double-layer structure. board.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com