Charring wood composite floor and manufacturing method thereof

A technology of composite flooring and carbonized wood, which is applied in the direction of manufacturing tools, building structures, wood processing appliances, etc., can solve problems such as warping and deformation, and achieve the goals of reducing deformation, saving surface board resources, and good biological durability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

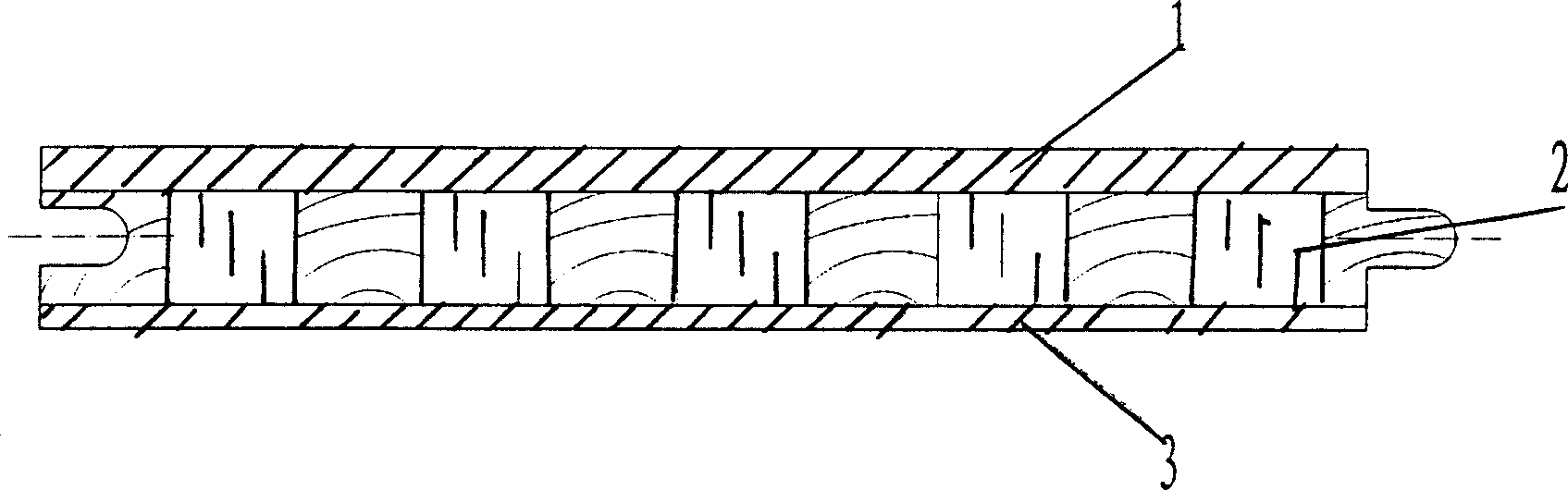

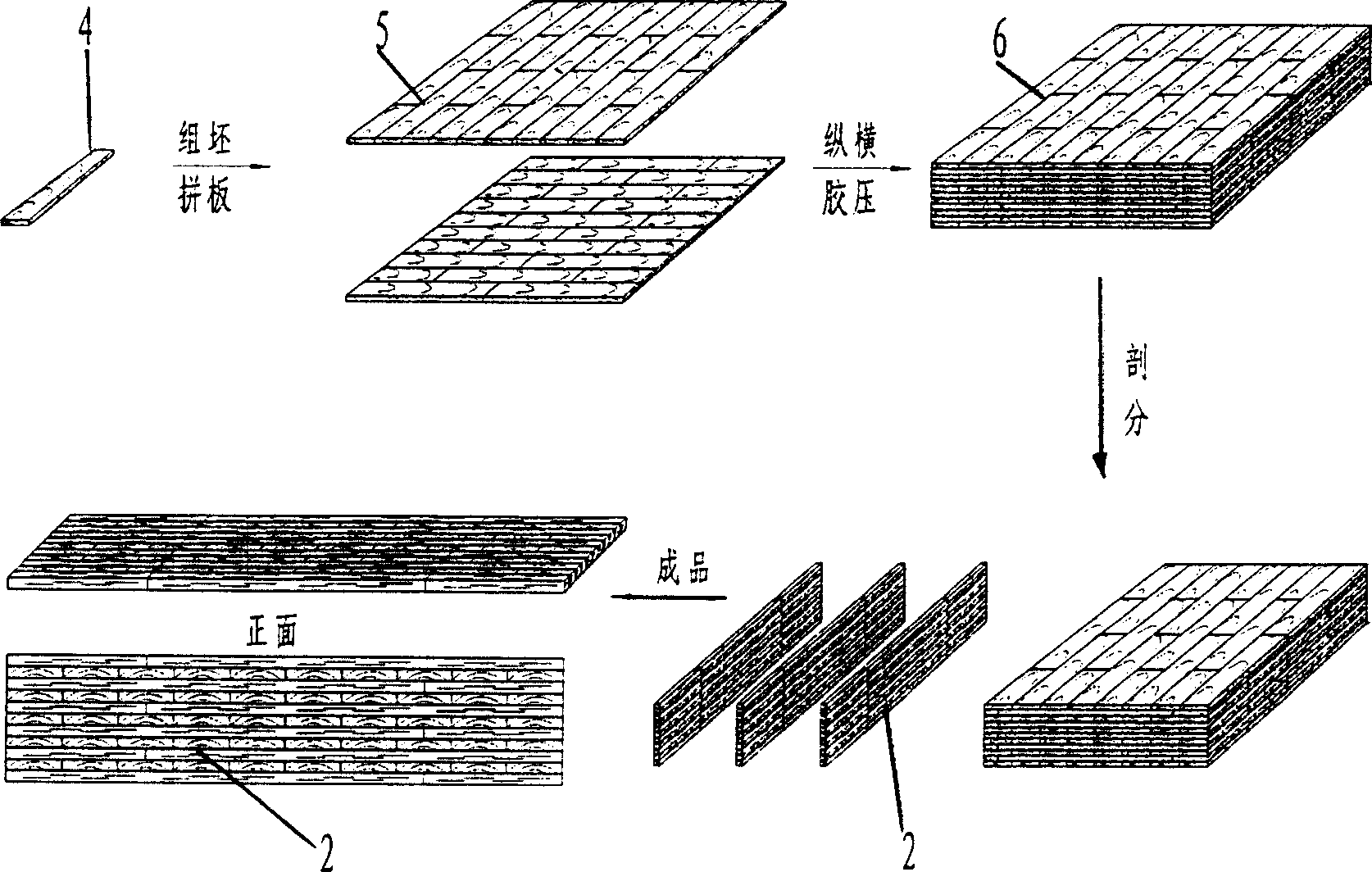

[0017] The specific manufacturing method of the three-layer carbonized wood composite floor comprises the following steps: 1. preparation of the surface material of the carbonized wood composite floor; 2. preparation of the core layer of the carbonized wood composite floor; 3. preparation of the bottom layer of the carbonized wood composite floor.

[0018] 1. Preparation of carbonized wood composite floor surface material: carbonize the 22mm-thick surface blank at a temperature of 180°C; Divided into three pieces of carbonized wood surface finished products with a thickness of 6mm;

[0019] 2. Preparation of the core layer of carbonized wood composite floor: dry the fast-growing material blank until its moisture content is about 8%, and process it into a fast-growing material sheet 4 according to the specification and size of the floor. The side of the sheet 4 is coated with urea-formaldehyde resin adhesive, and the amount of glue applied is 300g / m 2 , the thin plates 4 are ...

Embodiment 2

[0023] Specific manufacturing method of double-layer carbonized wood composite floor

[0024] When the surface layer adopts carbonized wood surface board and the base material adopts multi-layer plywood, the specific process is as follows:

[0025] ①Surface preparation: The surface blank (22mm thick) is dried to a moisture content of 8%, and the carbonization treatment temperature is 200°C. The carbonized wood surface blank is planed on all sides, and is divided into three pieces with a thickness of about 6mm by a frame saw or a splitting machine. Carbonized wood surface finished product 1;

[0026] ②Preparation of the bottom base material: the multi-layer plywood is machined according to the floor specifications to make the finished floor base material;

[0027] ③ Apply urea-formaldehyde glue on one side of the bottom substrate, the glue amount is 200g / m 2 , and attach the surface layer, after billet formation, one-way gluing, pressure 1.5MPa, 1.0min / mm plate when hot press...

Embodiment 3

[0029] Specific manufacturing method of double-layer carbonized wood composite floor

[0030] When the surface layer adopts carbonized wood surface board and the bottom substrate adopts high-density fiberboard, the specific process is as follows:

[0031] ①Surface preparation: mainly including drying the surface blank (22mm thick) to a moisture content of about 8%, carbonization treatment, and treating the carbonized wood surface blank at a temperature of 240°C, planing the carbonized wood surface blank on all sides, and cutting it into three thick pieces by frame saw or splitting machine Finished carbonized wood surface layer of about 6mm 1;

[0032] ②Preparation of the bottom base material: machine the high-density fiberboard according to the floor specifications to make the finished floor bottom layer;

[0033] ③ Apply urea-formaldehyde glue on one side of the bottom substrate, the glue amount is 200g / m 2 , and attach the surface layer, after billet formation, one-way glu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com