Anti-cracking floor heating solid wood composite floor and production method thereof

A solid wood composite flooring and floor heating technology, applied in the direction of chemical instruments and methods, layered products, wood layered products, etc., can solve the problems of water and heat energy consumption, energy, resource waste, hardwood price rise, etc., and achieve the risk of surface cracking Reduce, broaden market prospects, reduce the effect of heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

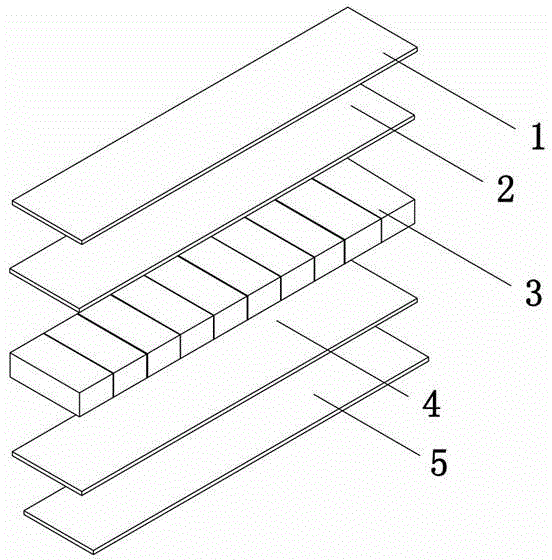

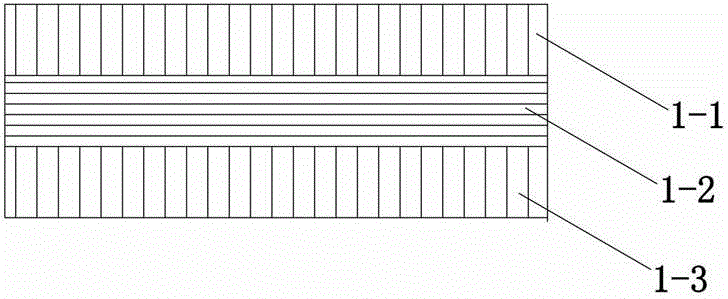

[0044] An anti-crack floor heating solid wood composite floor made of rotary cut veneer, which is sequentially glued together by a composite surface board 1, a non-woven fabric layer 2, a core board 3, a non-woven fabric layer 4, and a bottom board 5. The composite surface board 1 , the core board 3 and the bottom board 5 are arranged longitudinally, horizontally and vertically according to the wood grain, and the composite surface board 1 is provided with longitudinal grooves of 0.2-0.3mm depth on the back side of the rotary-cut hardwood surface board, and the groove width is 1mm. The length of the groove runs through and is equal to the length of the plate, and two grooves are evenly distributed in the direction of the plate width.

Embodiment 2

[0046] An anti-crack floor heating solid wood composite floor made of rotary cut veneer, which is sequentially glued together by a composite surface board 1, a non-woven fabric layer 2, a core board 3, a non-woven fabric layer 4, and a bottom board 5. The composite surface board 1 , the core board 3 and the bottom board 5 are arranged longitudinally, horizontally and vertically according to the wood texture, and the composite surface board 1 is provided with longitudinal grooves of 0.3-0.5mm depth on the back side of the rotary-cut hardwood surface board, and the groove width is 1mm. The length of the groove runs through and is equal to the length of the plate, and 3 grooves are evenly distributed in the direction of the plate width.

Embodiment 3

[0048] An anti-crack floor heating solid wood composite floor made of rotary cut veneer, which is sequentially glued together by a composite surface board 1, a non-woven fabric layer 2, a core board 3, a non-woven fabric layer 4, and a bottom board 5. The composite surface board 1 , the core board 3 and the bottom board 5 are arranged longitudinally, horizontally and vertically according to the wood grain, and the composite surface board 1 is provided with longitudinal grooves of 0.2-0.3mm depth on the back side of the rotary-cut hardwood surface board, and the groove width is 2mm. The length of the groove runs through and is equal to the length of the plate, and two grooves are evenly distributed in the direction of the plate width.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Groove width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com