Four-layer solid wood composite floor with skin layer having horizontal-longitudinal split joint structure and method for making same

A solid wood composite floor and solid wood board technology, applied in the field of building decoration materials, can solve the problems of easy cracking, poor strength, easy cracking of the surface plate, etc., and achieve the effects of enhancing bonding strength, improving stability, and saving precious tree species resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

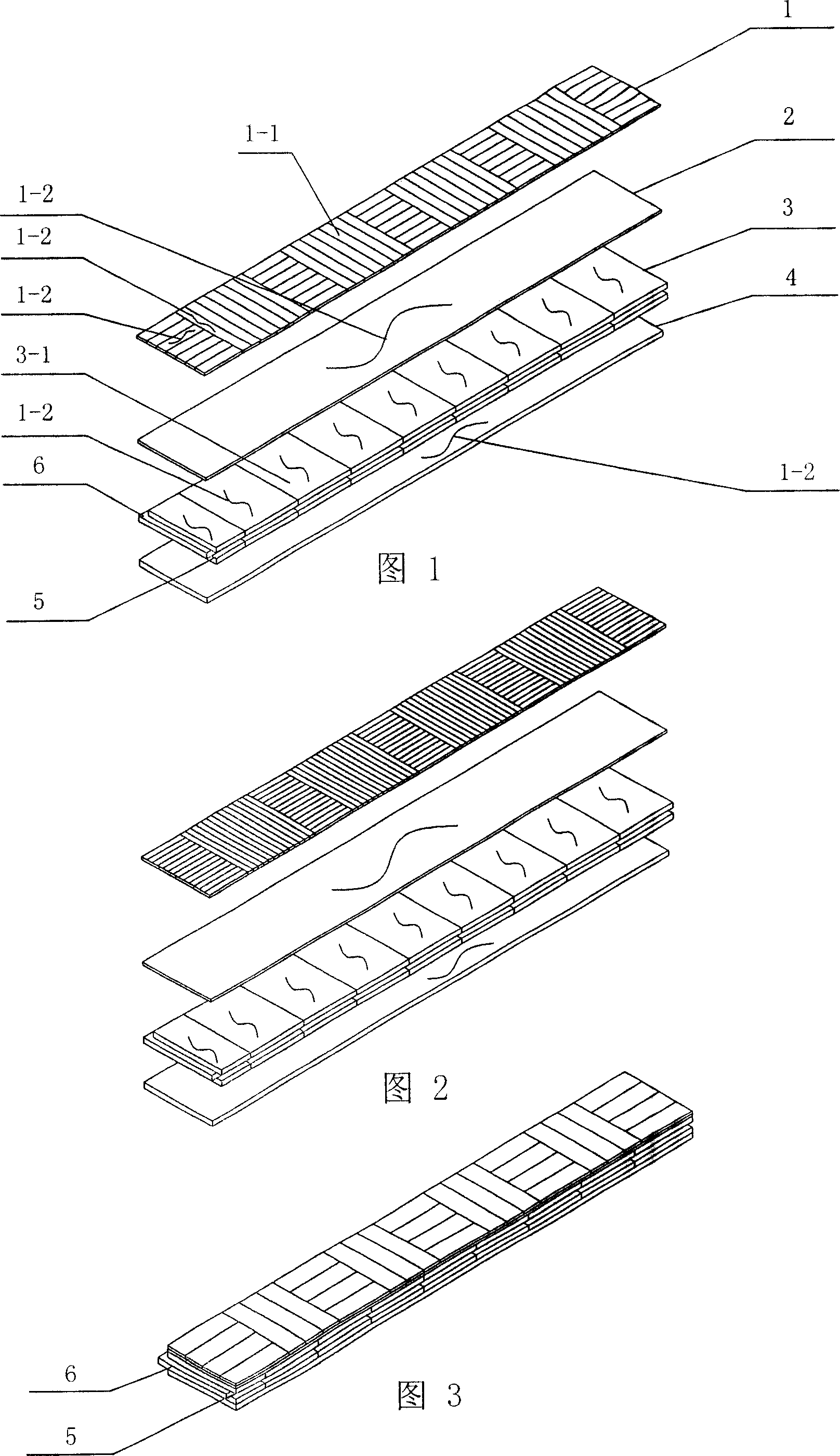

[0039] Referring to Figures 1 and 2, the surface solid wood board 1, the glued veneer 2, the core board 3 and the back board 4 are bonded to each other to form a solid wood composite floor, and there are tongue and groove 5 and grooves for splicing the floors around the floor. Tongue 6; wherein, the surface solid wood board 1 is composed of short wood blocks glued together horizontally and vertically along the direction of wood fibers 1-2; the short wood blocks are composed of at least two hard wood strips 1-1 spliced and glued together. The short wooden block in Fig. 1 of this embodiment is spliced and glued by seven hard wooden strips, and the short wooden block in Fig. 2 is spliced and glued by thirteen hard wooden strips, and the number of hard wooden strips depends on the width of the hard wooden strips , the width is narrow, the number of hard wood strips required to be spliced to the surface of the floor width is large, and vice versa; and the width of the short ...

Embodiment 2

[0043] Referring to Fig. 3 and embodiment 1,

[0044] Different from embodiment 1, the width of the horizontal and vertical short blocks of spliced surface solid wood board 1 is different; The width of the spliced short wood blocks can make more flexible use of hard wood materials, and at the same time, it can increase the different patterns of the floor surface boards while using short hard wood.

[0045] The hard wood strip in the above-mentioned embodiment 1 and embodiment 2 is hard wood such as oak or walnut or teak or merbau or balsam or jatoba or birch or maple or elm or Southwest birch or hard maple wood. The core board, glued veneer and backboard are soft woods; they are soft woods such as pine or eucalyptus or poplar or meranti.

Embodiment 3

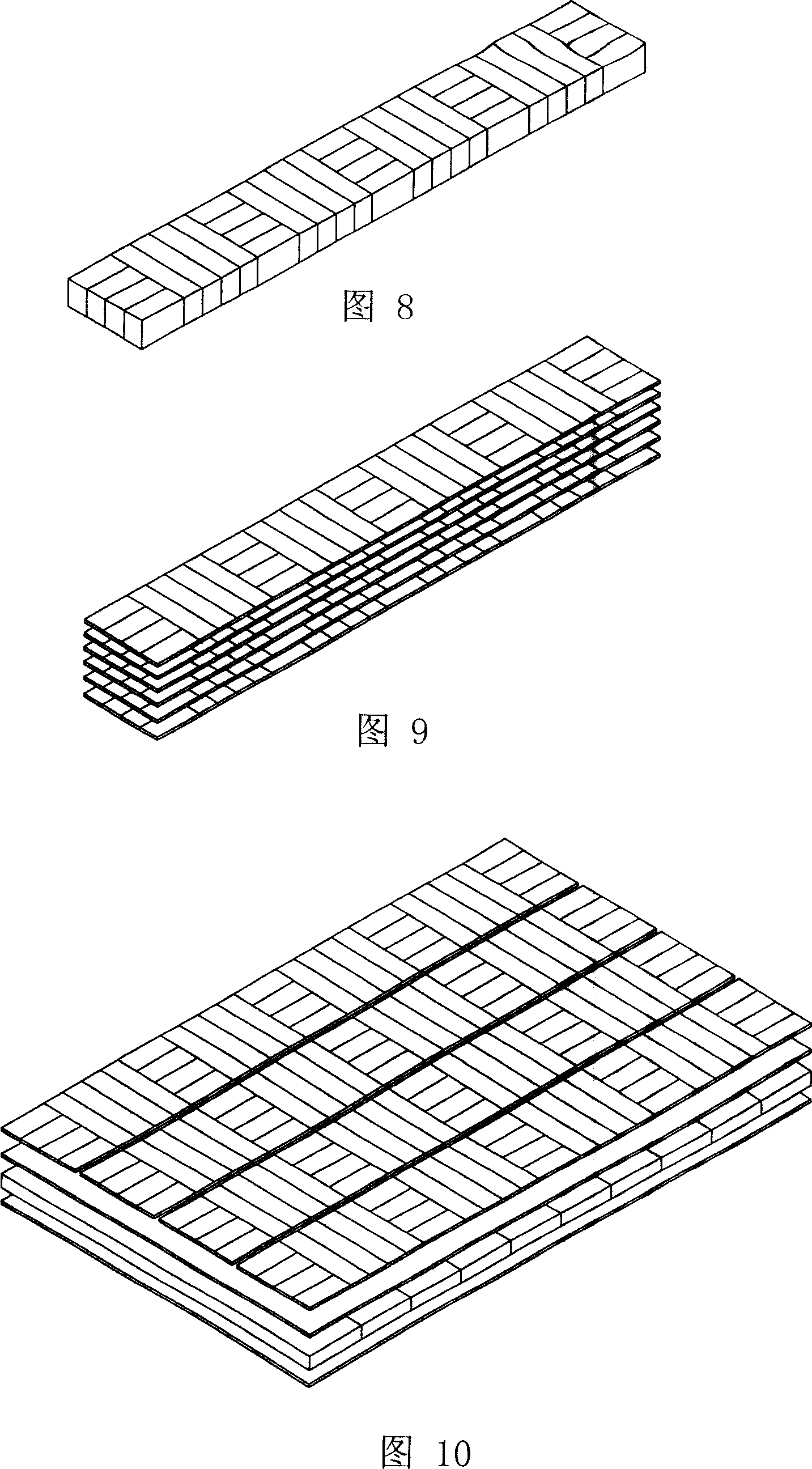

[0047] Referring to Fig. 12 and Example 1, the manufacturing process of the four-layer solid wood composite floor whose surface layer is a horizontal and vertical splicing structure is:

[0048] 12-1. Make surface solid wood slabs with horizontal and vertical splicing structures; process hard wood into short wooden slabs with uniform thickness, splice the short wooden slabs at 90 degrees horizontally and vertically along the wood fiber direction, and then frame Sawn into thin boards, planed on all sides, leveled, trimmed, sorted and balanced, and then used as surface solid wood boards;

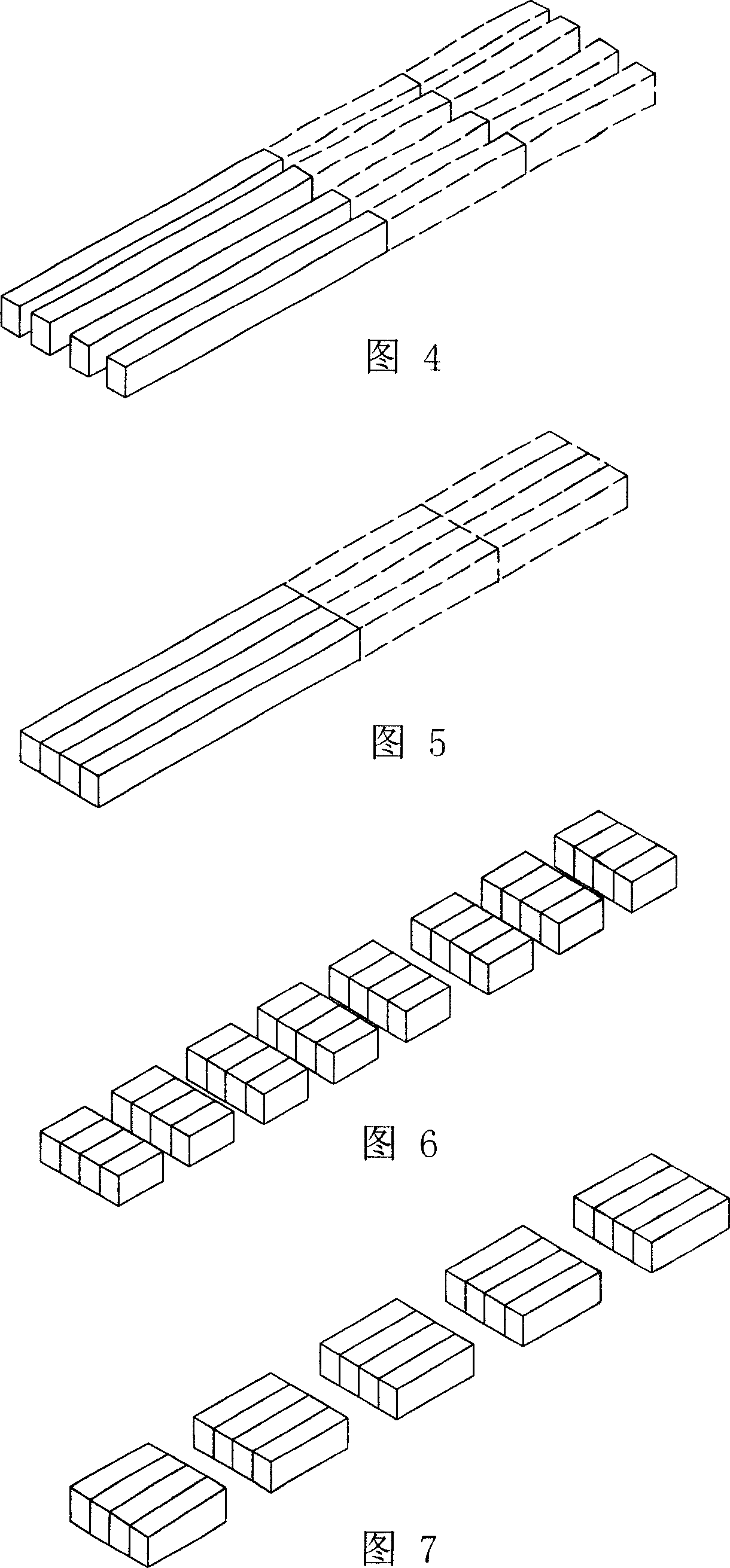

[0049]The specific steps are, see Figure 4, hard wood, that is, hard wood such as oak or walnut or teak or merbau or balsam or jatoba or birch or maple or elm or southwest birch or hard maple Short material, sawed and planed into hard wood strips, the dotted line in the figure shows the use of short hard wood of different lengths to saw and planed into hard wood strips; then see Figure 5, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com