Production method for flame-retardant solid wood flooring

A technology of solid wood flooring and production methods, applied to wood processing appliances, devices for coating liquid on the surface, manufacturing tools, etc., can solve problems such as economic losses, life safety threats, and flammability, and achieve low flame-retardant treatment costs, Simple production process and good flame retardant performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

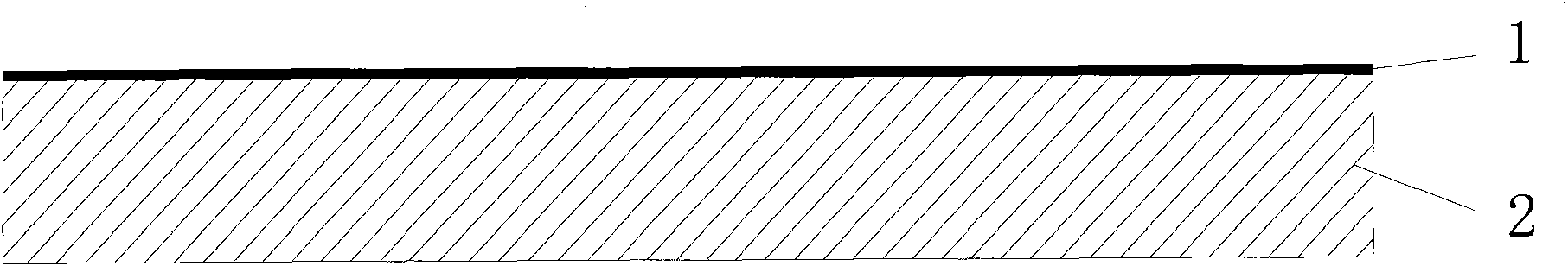

Image

Examples

Embodiment 1

[0025] 1) Process natural Thai teak logs into solid wood flooring strips with a size of 925mm×135mm×15.2mm;

[0026] 2) Dry the solid wood floor strips to a moisture content of 10%;

[0027] 3) The solid wood floor slab is obtained by curing, sanding, and mortising the solid wood floor strips after drying treatment. The health conditions are: a health room with a temperature of 25°C and a humidity of 12% for 5 days;

[0028] 4)Using UV paint to paint the surface layer of solid wood floor slabs, using the process of 9 bottoms and 2 sides, the paint sequence is water-based primer → putty → elastic primer → wear-resistant primer → wear-resistant primer → back paint → Transparent primer → sanding → wear-resistant primer → hardened primer → transparent primer → sanding → top coat → top coat. The wear-resistant primer is added with 20% by mass mixed flame retardant, the hardened primer is added with 20% by mass mixed flame retardant, and the top coat is added with 8% by mass mixed flame ...

Embodiment 2

[0032] 1) Process natural ebony logs into solid wood flooring strips with a size of 925mm×135mm×12.2mm;

[0033] 2) Dry the solid wood floor strips to a moisture content of 10%;

[0034] 3) The solid wood floor slab is obtained by curing, sanding, and mortising the solid wood floor strips after drying treatment. The health conditions are: a health room with a temperature of 25°C and a humidity of 12% for 6 days;

[0035] 4)Using UV paint to paint the surface layer of solid wood floor slabs, using the process of 9 bottoms and 2 sides, the paint sequence is water-based primer → putty → elastic primer → wear-resistant primer → wear-resistant primer → back paint → Transparent primer → sanding → wear-resistant primer → hardened primer → transparent primer → sanding → top coat → top coat. The wear-resistant primer is added with 15% by mass mixed flame retardant, the hardened primer is added with 25% by mass mixed flame retardant, and the top coat is added with 7% by mass mixed flame reta...

Embodiment 3

[0039] 1) Process natural black walnut logs into solid wood flooring strips with a size of 925mm×135mm×18.2mm;

[0040] 2) Dry the solid wood floor strips to a moisture content of 10%;

[0041] 3) The solid wood floor slab is obtained by curing, sanding, and mortising the solid wood floor strips after drying treatment. The health conditions are: a health room with a temperature of 25°C and a humidity of 12% for 3 days;

[0042] 4)Using UV paint to paint the surface layer of solid wood floor slabs, using the process of 9 bottoms and 2 sides, the paint sequence is water-based primer → putty → elastic primer → wear-resistant primer → wear-resistant primer → back paint → Transparent primer → sanding → wear-resistant primer → hardened primer → transparent primer → sanding → top coat → top coat. The wear-resistant primer is added with 18% by mass mixed flame retardant, the hardened primer is added with 22% by mass mixed flame retardant, and the top coat is added with 6% by mass mixed fla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com