Strengthening type three-layered wood compound floor board and mfg. method thereof

A technology of solid wood composite flooring and its manufacturing method, which is applied in the field of reinforced three-layer solid wood composite flooring and its production, and can solve problems such as debonding, glue separation between the surface layer board and the core layer board, and easy cracking of the surface layer board, so as to reduce the probability of cracking , prevent the glue layer from cracking, and improve the stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

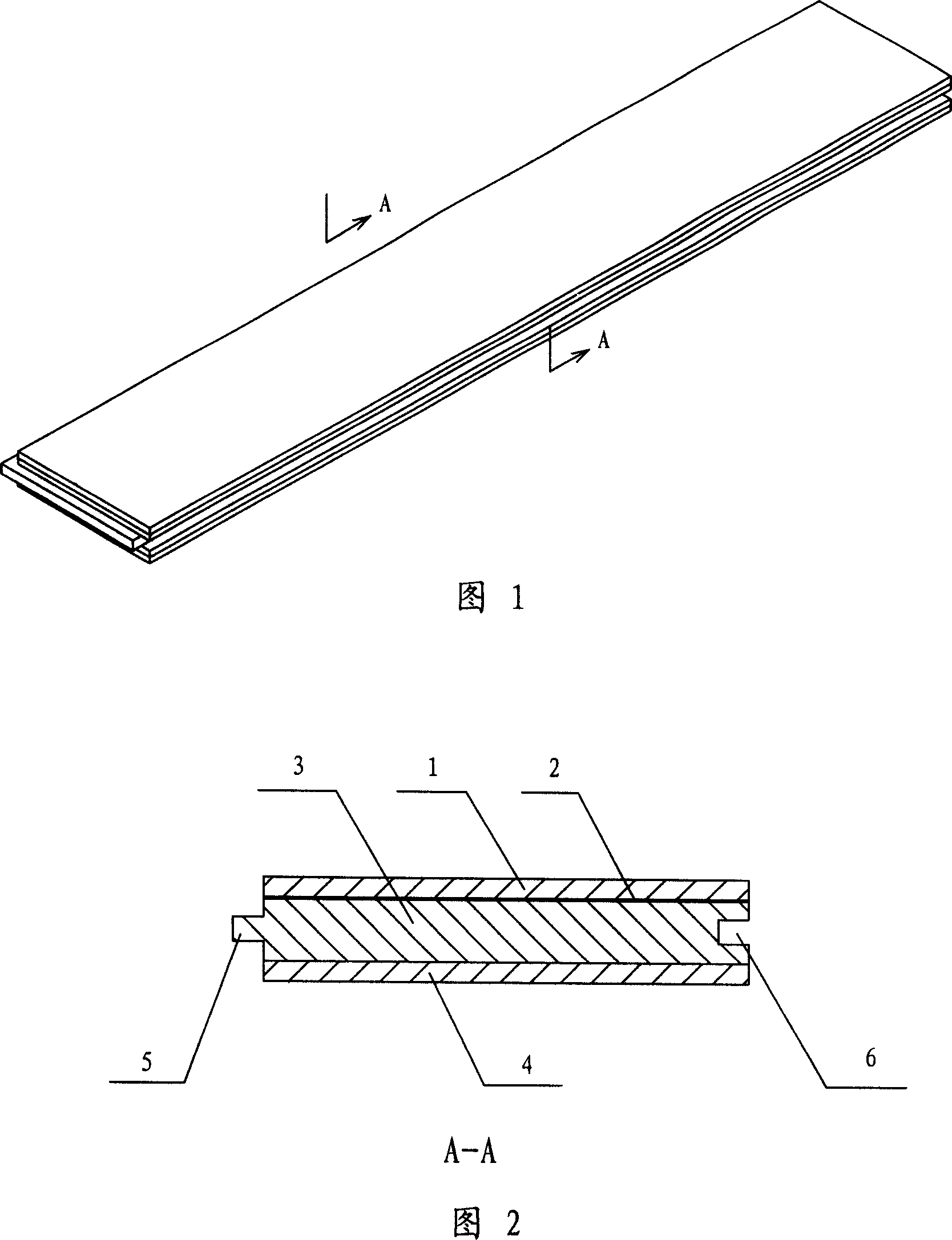

[0027] Referring to Fig. 1, Fig. 2, wherein, surface solid wood board 1 is hard wood such as oak, walnut, teak, merbau, balsam, jatoba, birch, maple, elm, southwest birch, hard maple and other materials; chemical fiber non-woven fabric 2 uses 10-50g / m 2 chemical fiber non-woven fabric; one side of the core board 3 is coated with an adhesive and non-woven fabric, and the surface solid wood board 1 is bonded together through the non-woven fabric; the other side of the core board 3 is glued to the backboard 4 connected together; there are floor tenon grooves 5 and floor tenons 6 around the core board 3 .

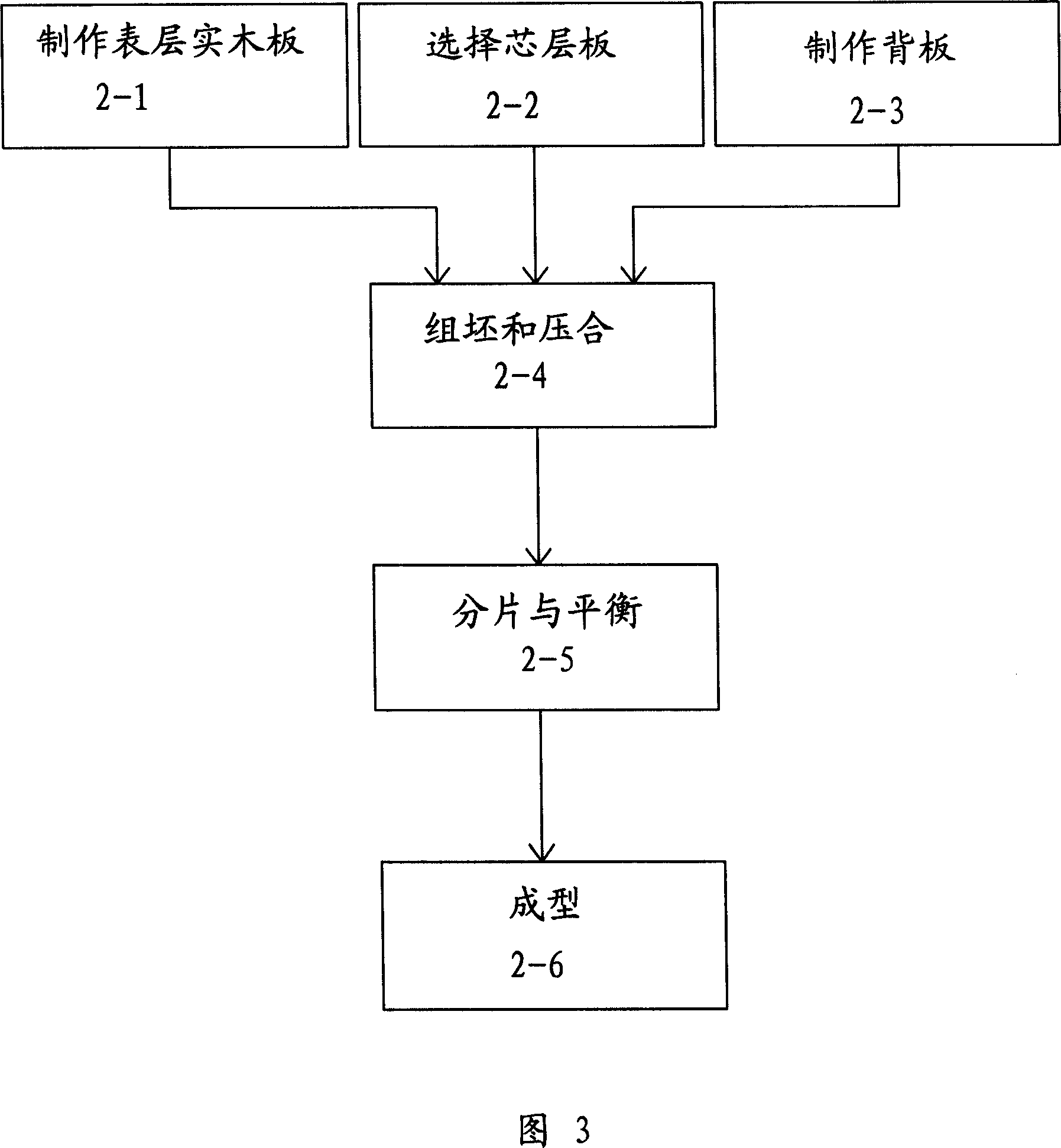

[0028] Referring to Fig. 2, the three-layer reinforced parquet manufacturing process flow chart, wherein,

[0029] 2-1, making the surface solid wood board; dry sawing the hard wood and planing on all sides to form a solid wood board, then saw the solid wood board into boards, that is, the surface solid wood board, put the surface solid wood board into a drying kiln to dry, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com