Parquet using laminated veneer lumber strip as base material and production method thereof

A technology of solid wood composite flooring and laminated veneer lumber, which is applied to wood processing equipment, floors, manufacturing tools, etc., can solve the problems of loss of solid wood composite flooring mechanical properties, warping and deformation of solid wood composite flooring, and failure to achieve balance. Achieve the effects of good mechanical properties, avoid warping and deformation, and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

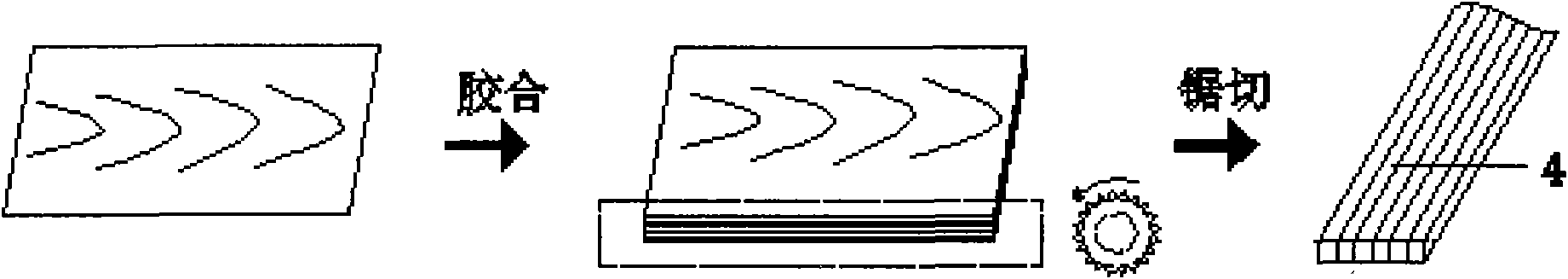

[0031] The present invention utilizes the production technology and production equipment of existing laminated veneer lumber and solid wood composite floor, and adopts the following process steps:

[0032]1. Cut the poplar wood into veneers with a thickness of 3mm, dry the veneers to a moisture content of 8%, and repair the defects of the veneers, such as knots, insect holes, and decay;

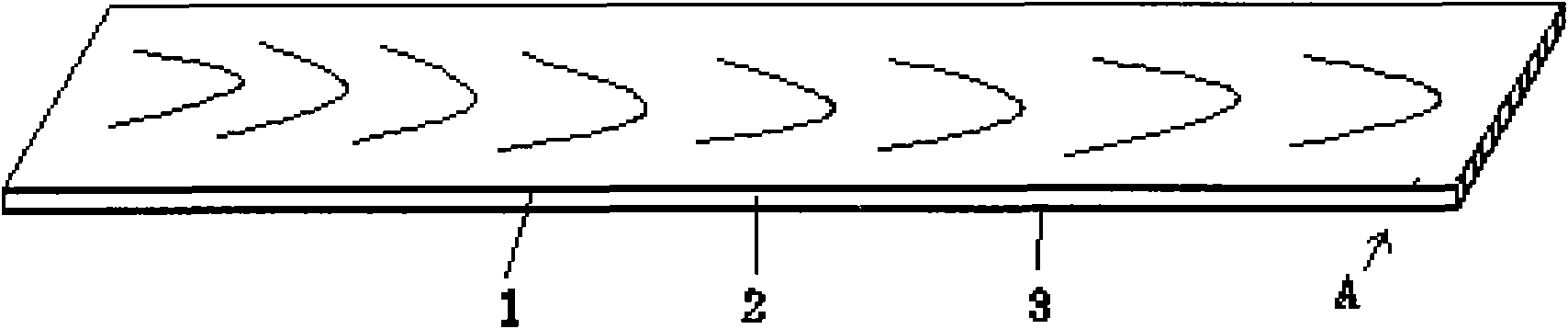

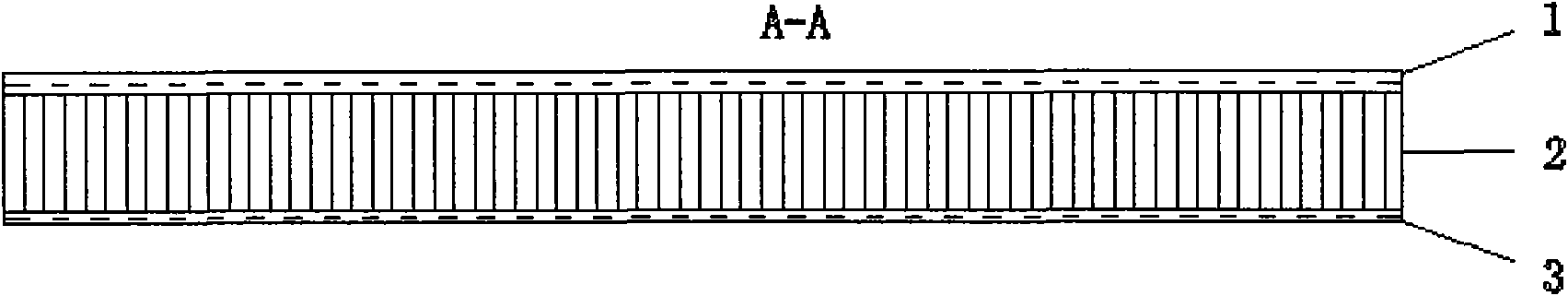

[0033] 2. Through a series of processes such as veneer finishing, gluing, billet assembly, cold pressing, and hot pressing, the veneer is made into a laminated veneer lumber slab with a thickness of 135mm that is mainly assembled along the grain. Among them, veneer finishing refers to the preparatory work of veneer lengthening and billet assembly; the adhesive is modified urea-formaldehyde resin glue, and the amount of glue applied is 350g / m on both sides 2 ;The cold pressing condition is: keep the pressure of 1.2MPa at room temperature for 120 minutes; the hot pressing condition is: the temp...

Embodiment 2

[0038] Change the process step 2 of Example 1 to: through a series of processes such as veneer finishing, gluing, billet assembly, cold pressing, and hot pressing, the veneer is made into a veneer layer with a thickness of 70mm as the main billet along the grain Lumber slabs. The adhesive is modified urea-formaldehyde resin, and the amount of glue applied is 350g / m2 on both sides; the cold pressing conditions are: 1.0MPa pressure at room temperature for 120 minutes; the hot pressing conditions are: temperature 110°C, time 1 minute / mm, pressure 1.0MPa ;

[0039] Change the process step 3 of Example 1 to: prepare a laminated veneer lumber slab with a thickness of 70 mm, use a multi-blade saw to strip the laminated veneer lumber slab, and use a four-sided planer to cut the laminated veneer lumber slab Processed into slats with a width of 68mm and a thickness of 14.2mm, the obtained LVL slats are then spliced laterally into slats with a width of 136mm and a thickness of 14.2mm,...

Embodiment 3

[0042] 1. Cut the poplar wood into veneers with a thickness of 3mm, dry the veneers to a moisture content of 8%, and repair the defects of the veneers, such as knots, insect holes, and decay;

[0043] 2. Through a series of processes such as veneer finishing, gluing, billet assembly, cold pressing, and hot pressing, the veneer is made into a laminated veneer lumber slab with a thickness of 60mm that is mainly assembled along the grain. The adhesive is modified urea-formaldehyde resin glue, and the amount of glue applied is 350g / m on both sides 2 ;The cold pressing condition is: keep the pressure of 1.0MPa at room temperature for 90 minutes; the hot pressing condition is: the temperature is 110°C, the time is 1 minute / mm, and the pressure is 1.0MPa;

[0044] 3. Prepare a laminated veneer lumber slab with a thickness of 60 mm, and use a multi-blade saw to strip the laminated veneer lumber slab to obtain a strip with a width of 60 mm and a thickness of 14.2 mm, and the obtained l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com