Photocatalyst antibacterial solid wood composite floor board and production process of photocatalyst antibacterial solid wood composite floor board

A solid wood composite floor, photocatalyst antibacterial technology, applied in the direction of wood processing equipment, manufacturing tools, layered products, etc., can solve the problems of floor structure and performance to be improved, and achieve improved photocatalytic activity, stable performance, and high environmental protection Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

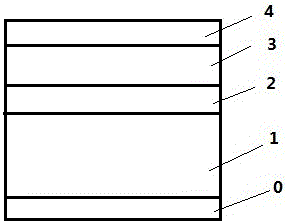

Image

Examples

Embodiment 1

[0057] The production process of photocatalyst antibacterial solid wood composite floor:

[0058] 1. Middle board finishing: The purchased eucalyptus or mixed wood middle boards are sorted according to the feeding standards, mainly according to their appearance grades. The feeding of materials that meet the standards needs to strictly control the moisture content;

[0059] 2. Glue adjustment: the additives and soybean flour are mixed at a ratio of 1.5:1, and the electric mixer is used for high-speed stirring for 5 minutes to make it fully mixed and uniform to make biomass soybean gum with a viscosity of 30,000 cps; additives include water and alkali , Polyvinyl alcohol, hexamethyl-epichlorobutane, kaolin and isocyanate;

[0060] 3. Glue cloth and blank assembly: Glue the finished middle plate. The glue needs to be evenly distributed and the amount of glue is controlled at 160g / m 2 , No flower glue phenomenon;

[0061] 4. Cold pressing: Put the assembled slabs into the cold press for c...

Embodiment 2

[0084] The production process of photocatalyst antibacterial solid wood composite floor:

[0085] 1. Middle board finishing: The purchased eucalyptus or mixed wood middle boards are sorted according to the feeding standards, mainly according to their appearance grades. The feeding of materials that meet the standards needs to strictly control the moisture content;

[0086] 2. Glue adjustment: the additives and soybean flour are mixed at a 2.5:1 ratio, and the electric mixer is used for high-speed stirring for 15 minutes to make it fully mixed to make biomass soybean gum, the viscosity is controlled at 100000 cps; the additives include water and alkali , Polyvinyl alcohol, hexamethyl-epichlorobutane, kaolin and isocyanate;

[0087] 3. Glue cloth and blank assembly: Glue the finished middle plate. The glue should be uniformly distributed, and the glue amount should be controlled at 220g / m. 2 , No flower glue phenomenon;

[0088] 4. Cold pressing: Put the assembled slabs into the cold pr...

Embodiment 3

[0111] The production process of photocatalyst antibacterial solid wood composite floor:

[0112] 1. Middle board finishing: The purchased eucalyptus or mixed wood middle boards are sorted according to the feeding standards, mainly according to their appearance grades. The feeding of materials that meet the standards needs to strictly control the moisture content;

[0113] 2. Glue adjustment: the additives and soybean flour are mixed at a ratio of 2:1, and the electric mixer is used for high-speed stirring for 10 minutes to make it fully mixed and uniform to make biomass soybean gum with a viscosity of 90000 cps; additives include water and alkali , Polyvinyl alcohol, hexamethyl-epichlorobutane, kaolin and isocyanate;

[0114] 3. Glue cloth and blank assembly: Glue the finished middle plate. The glue should be uniformly distributed, and the glue amount should be controlled at 200g / m 2 , No flower glue phenomenon;

[0115] 4. Cold pressing: Put the assembled slabs into the cold press f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com