Five-layered thick core wood compound floor board and mfg. method thereof

The technology of a solid wood composite floor and a manufacturing method, which is applied in the field of building decoration materials, can solve the problems of degumming and wave of the surface board, and achieve the effects of solving the poor bonding strength, reducing the thickness and improving the stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

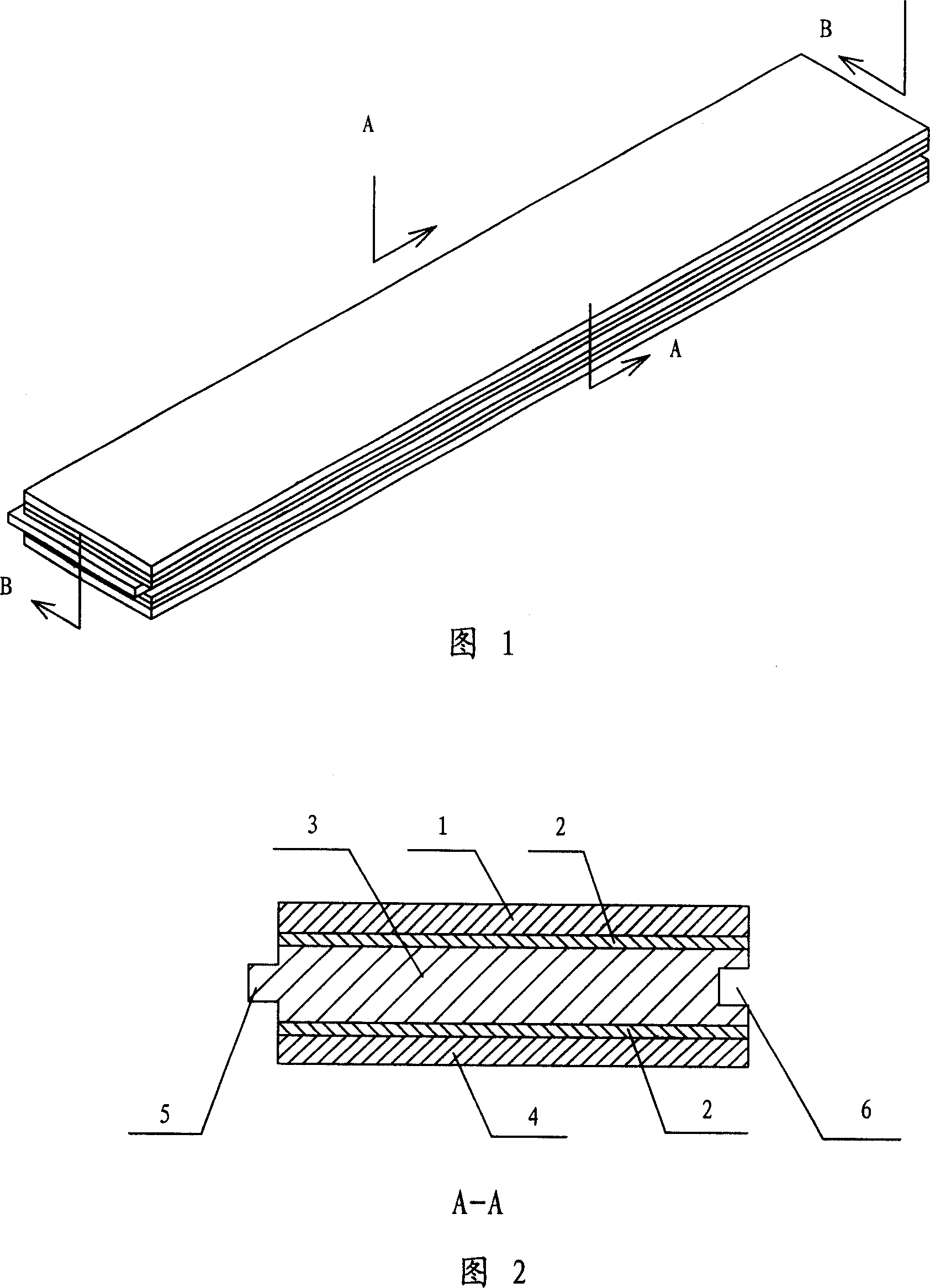

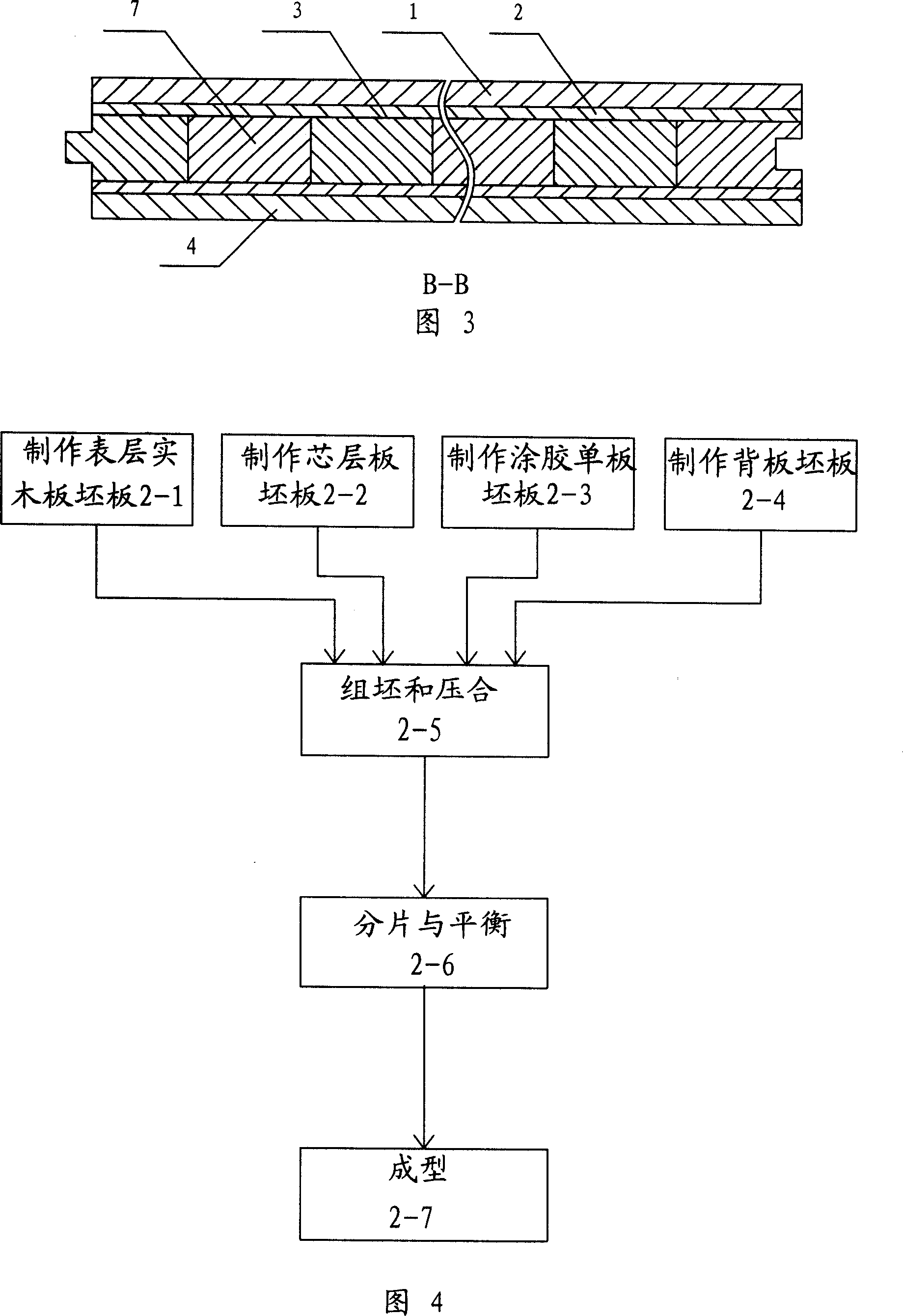

[0031] Referring to Fig. 1, Fig. 2, Fig. 3, wherein, surface solid wood board 1 is 0.3mm-4mm thick hard wood, such as oak or walnut or teak or merbau or balsam or jatoba or birch or maple or hard wood such as elm or southwest birch or hard maple; glued veneer 2 is soft wood of 0.5-3mm, such as pine or eucalyptus or poplar or meranti and other soft wood; core board 3 is It is composed of 1-30mm soft wood, such as pine or eucalyptus or poplar or meranti, which are processed into wooden strips 7 of the same thickness and spliced together; the thickness of the glued veneer must be smaller than the thickness of the core board 3; Because a layer of relatively thin glued veneer 2 is added between the thicker core board 3 and the thinner surface board 1, it can effectively solve the degumming and wave phenomenon of the surface board. The back board 4 is 1mm-3mm soft wood such as pine or eucalyptus or soft wood such as poplar or eucalyptus; The wood fiber directions of 4 are perpend...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com