Patents

Literature

34results about How to "Eliminate waves" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

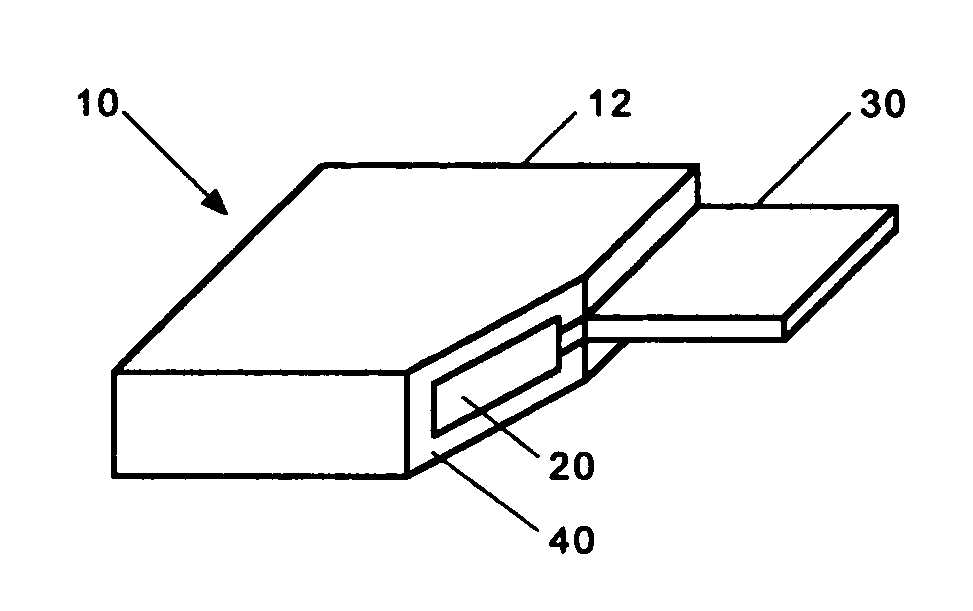

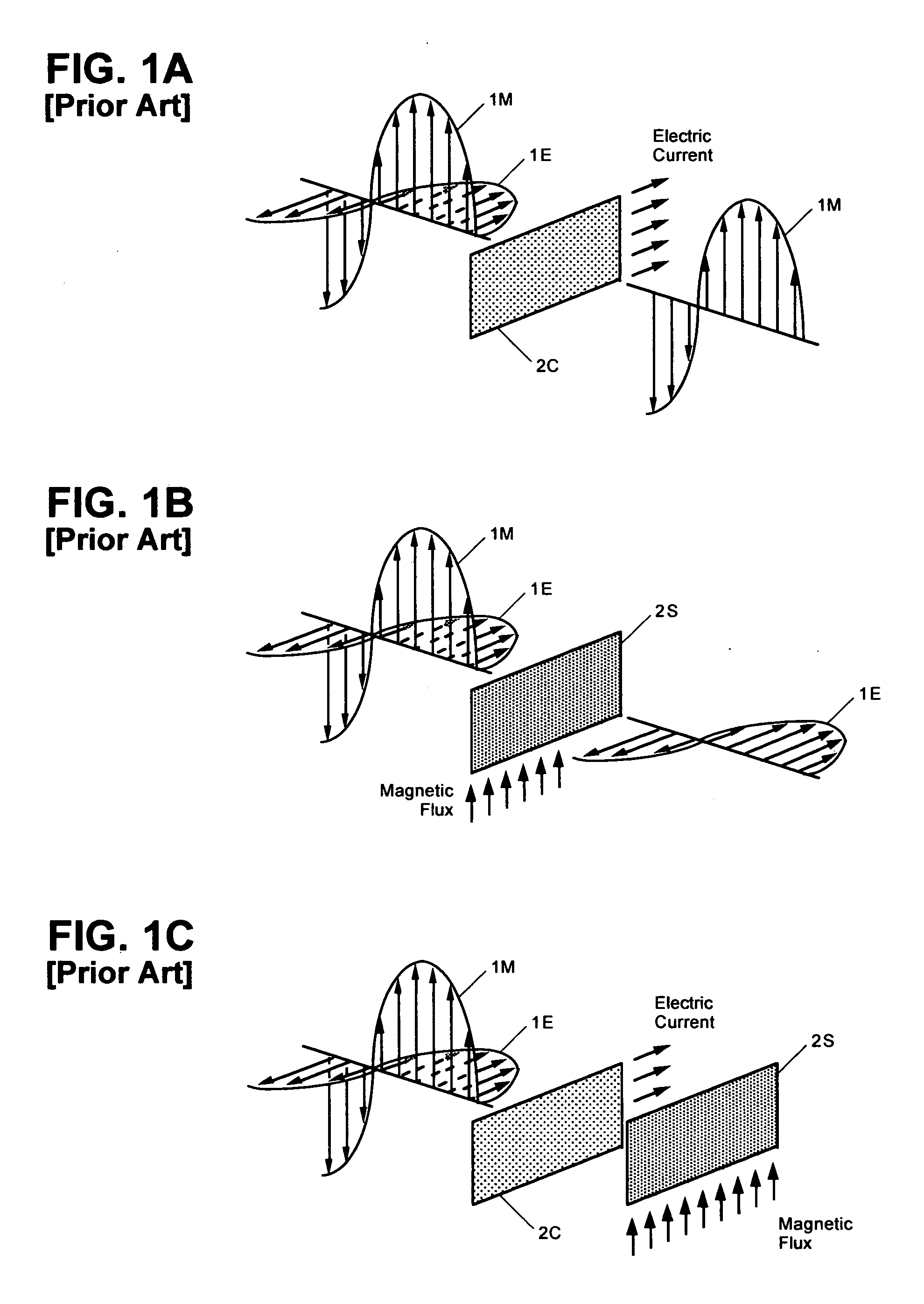

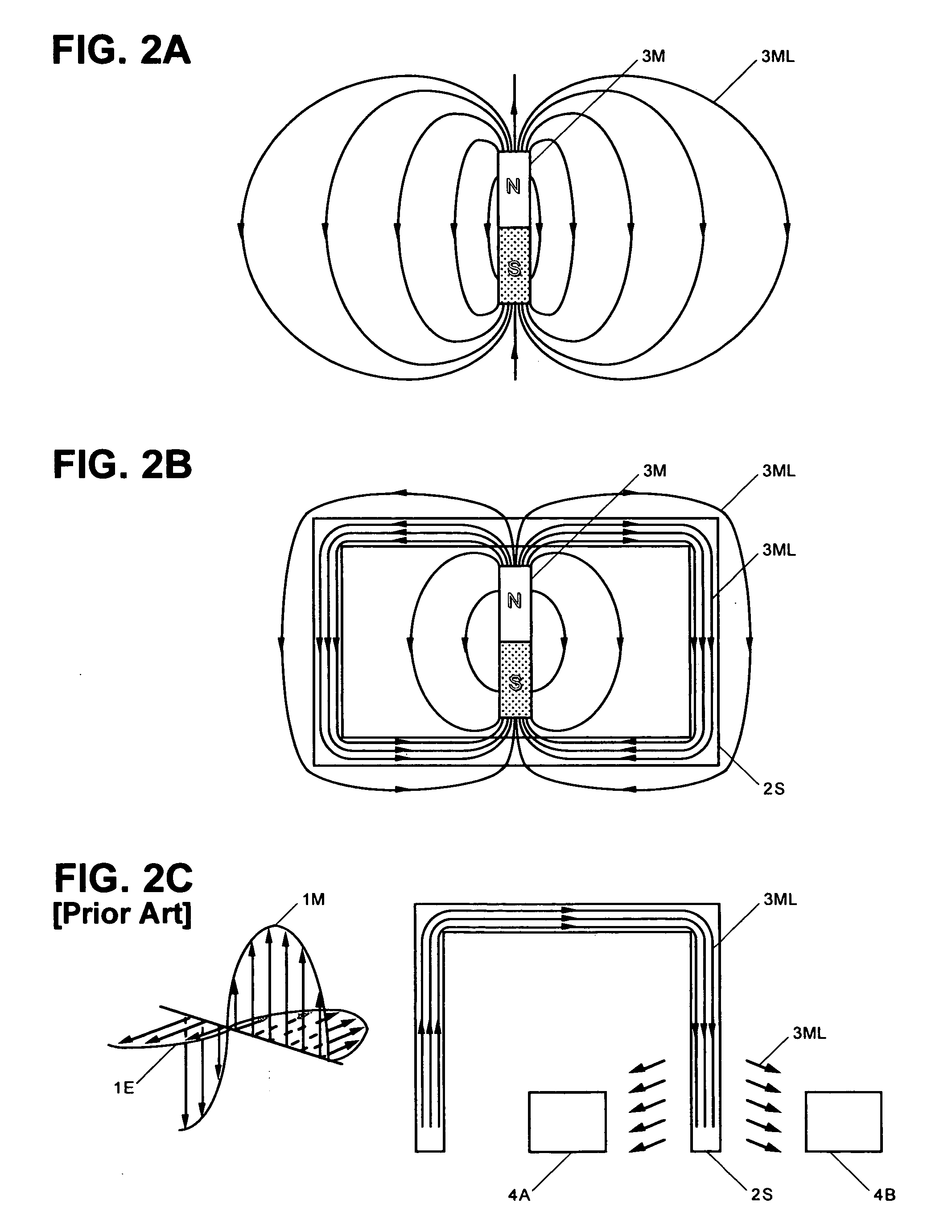

Magnet-shunted systems and methods

InactiveUS20070046408A1Eliminate wavesMinimize the path and/or shunt membersActive shieldingMagnetsPhysicsMagnet

The present invention relates to a magnet-shunted system for shielding a target from magnetic fields and waves. More particularly, the present invention relates to a magnet system including a path member and a magnet member having a magnet at least partially shielded by a magnetically permeable shunt member. The path member forms a path through which the extrinsic magnetic fields and waves bypass the target, the magnet member serves as a termination point for the magnetic fields or waves, and the shunt member defines another path through which primary magnetic fields generated by the magnet member are confined very close to the shunt and / or magnet members. The present invention relates to various methods of forming the termination point, eliminating the extrinsic magnetic fields or waves by the magnet, and disposing the magnet member into the path member. The present invention also relates to various processes for providing such a magnet-shunted system including the foregoing magnet and path members along with the optional shunt member.

Owner:SHIM YOUNGTACK

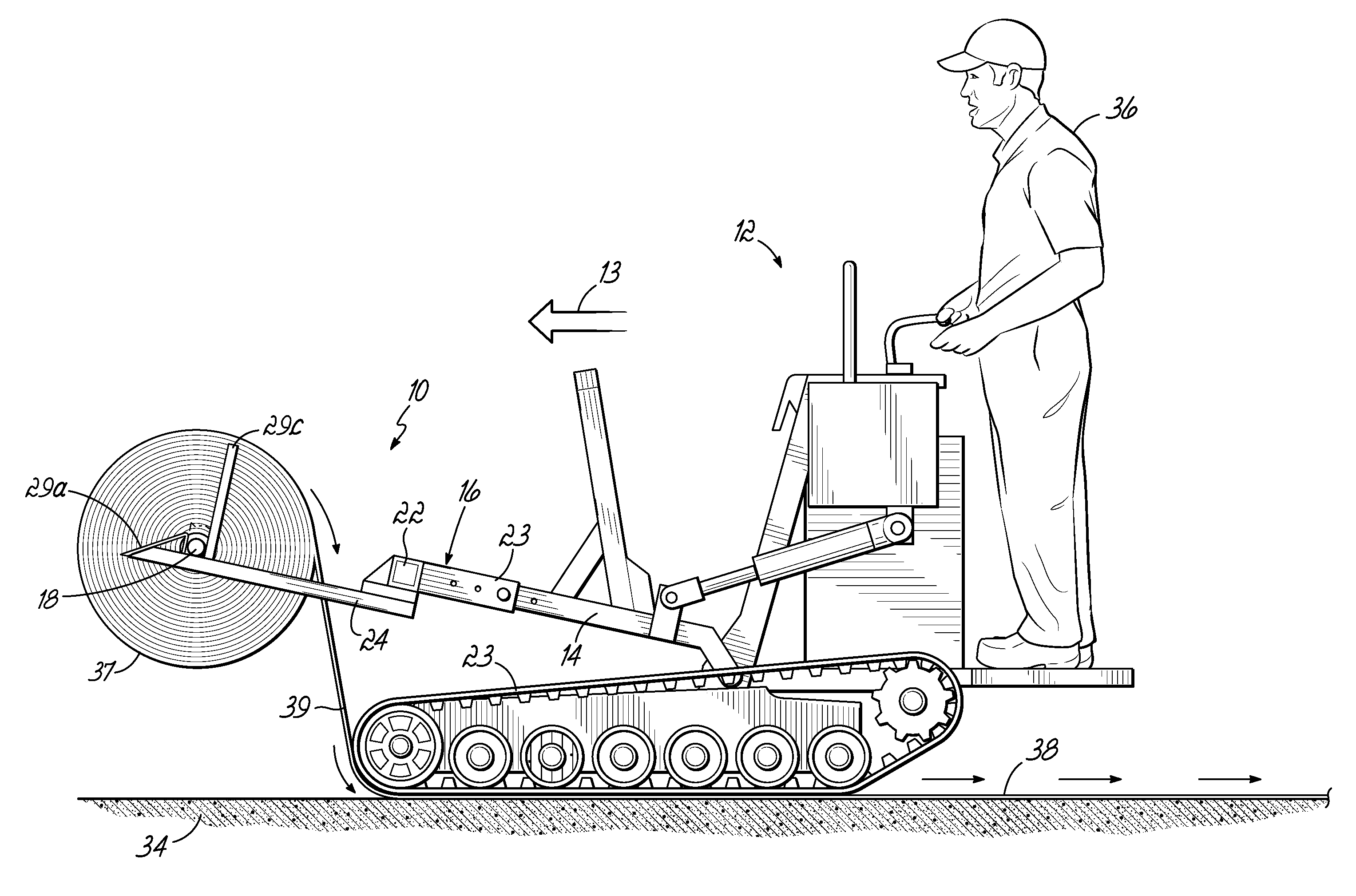

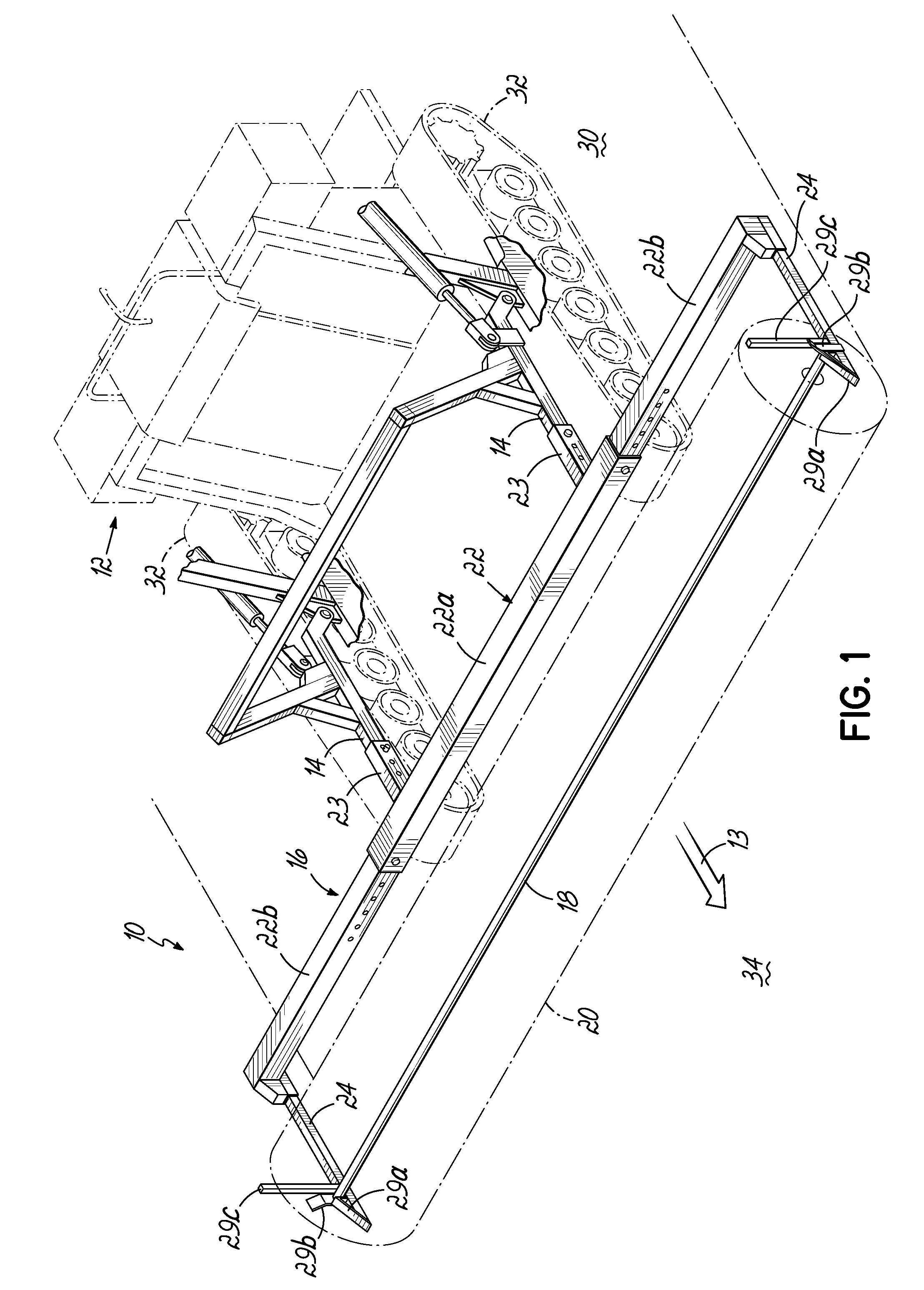

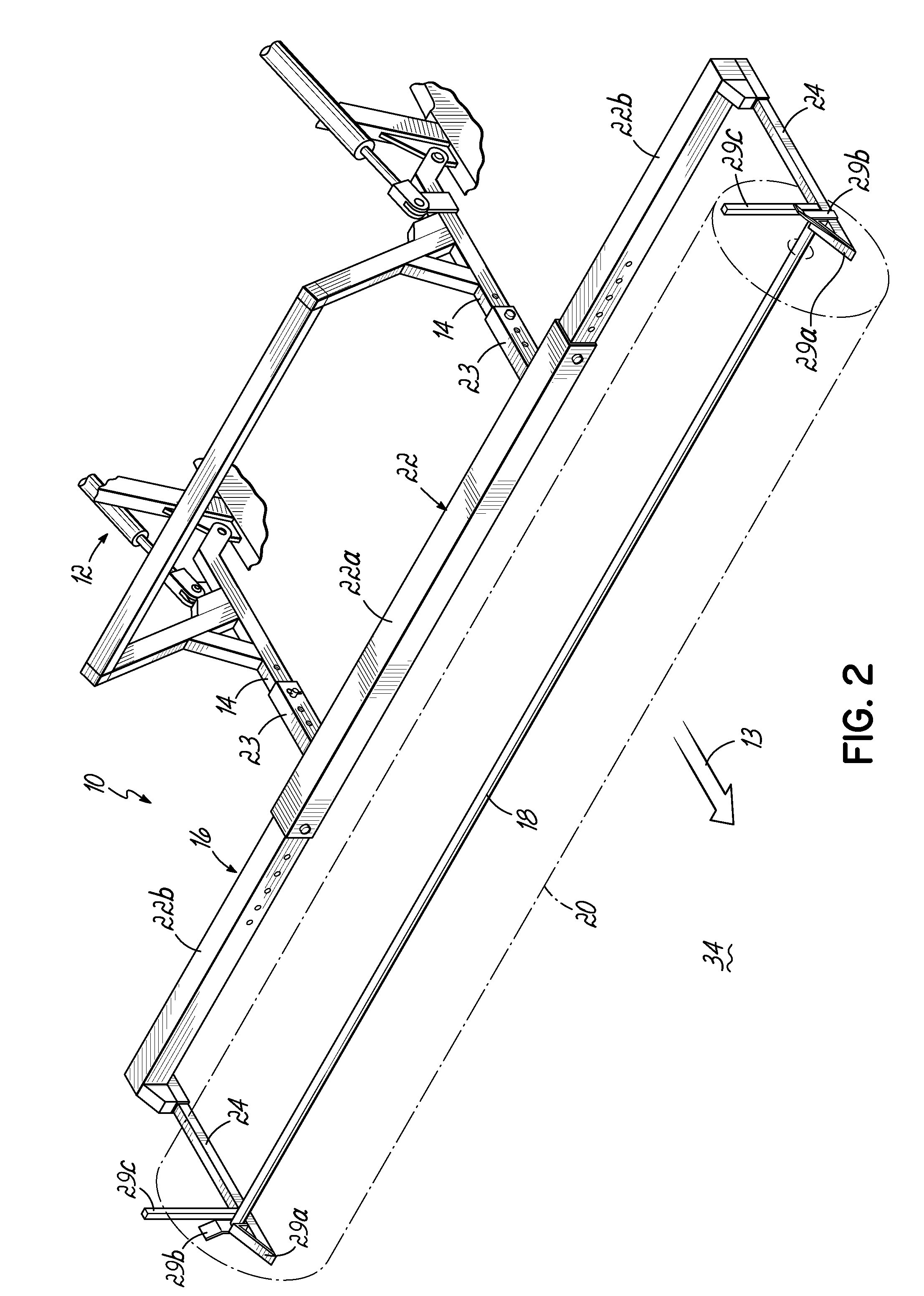

Method And Device For Installing Synthetic Turf

ActiveUS20120067996A1Improve efficiencyEliminate wave and wrinkleHops/wine cultivationFilament handlingEngineeringTransverse dimension

Owner:TECH LICENSING CORP (US)

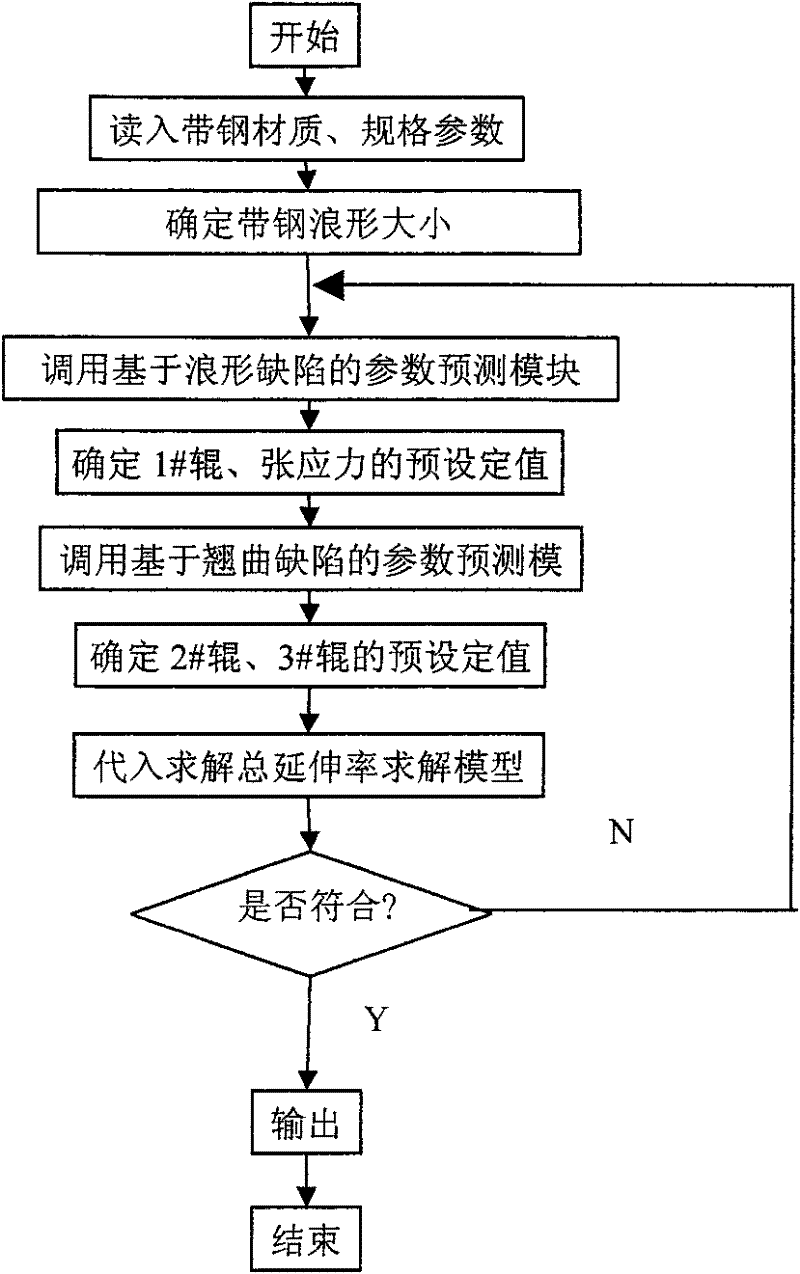

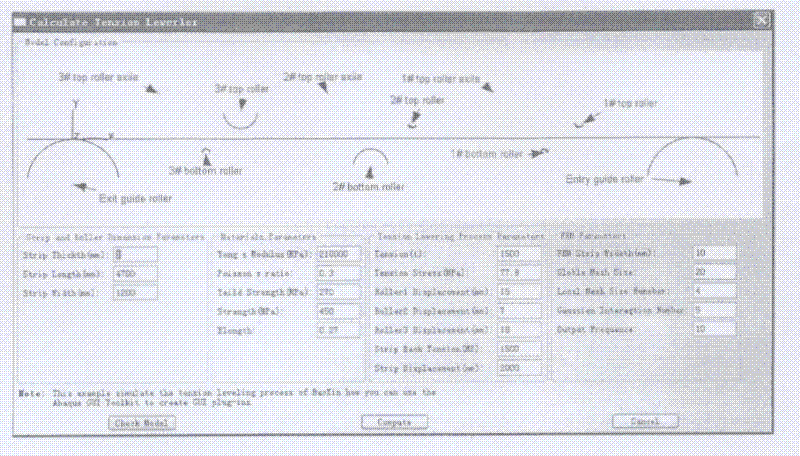

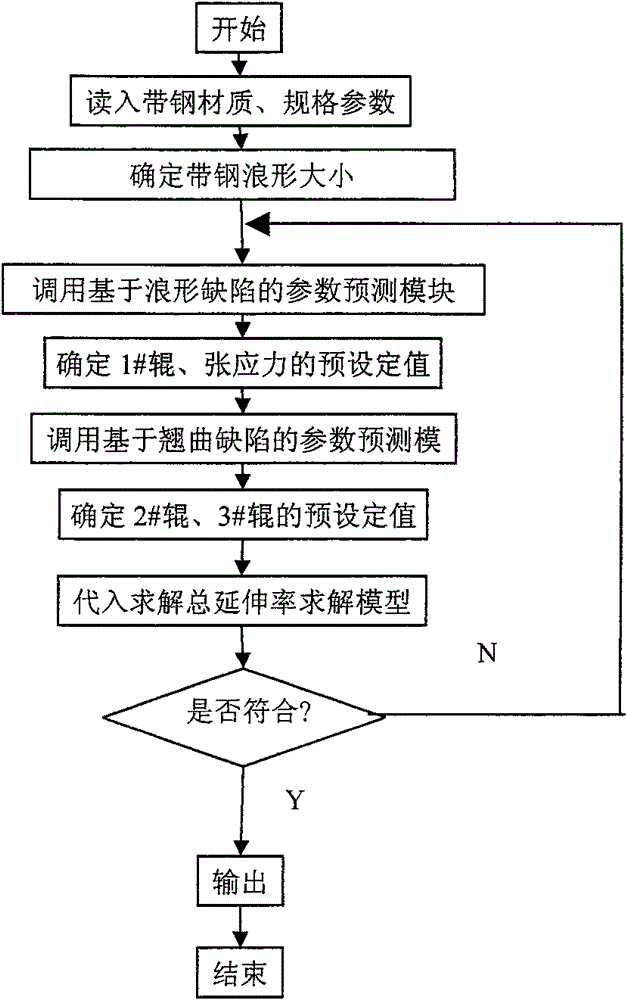

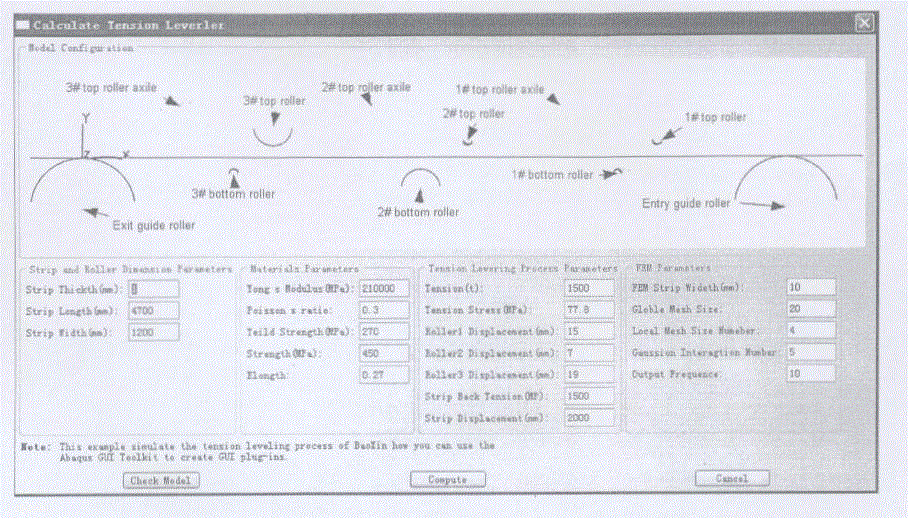

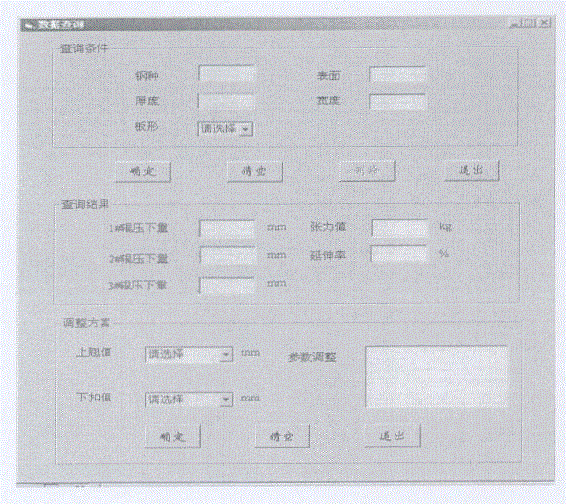

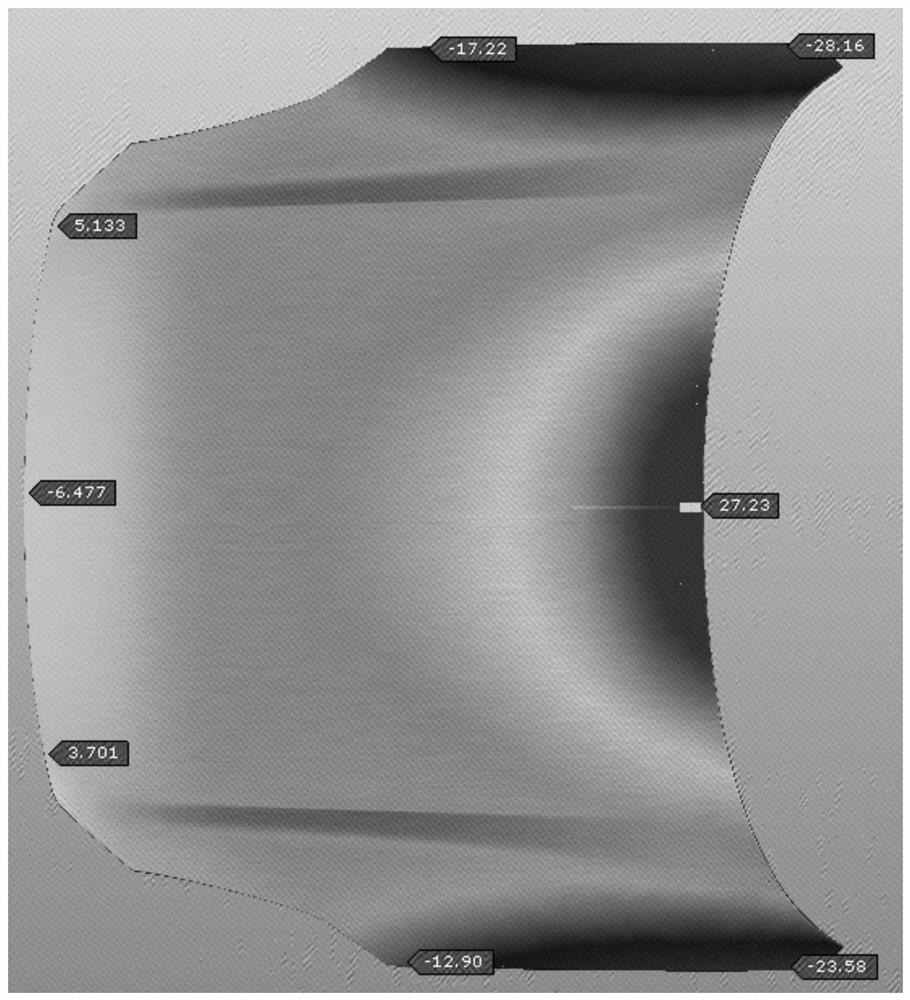

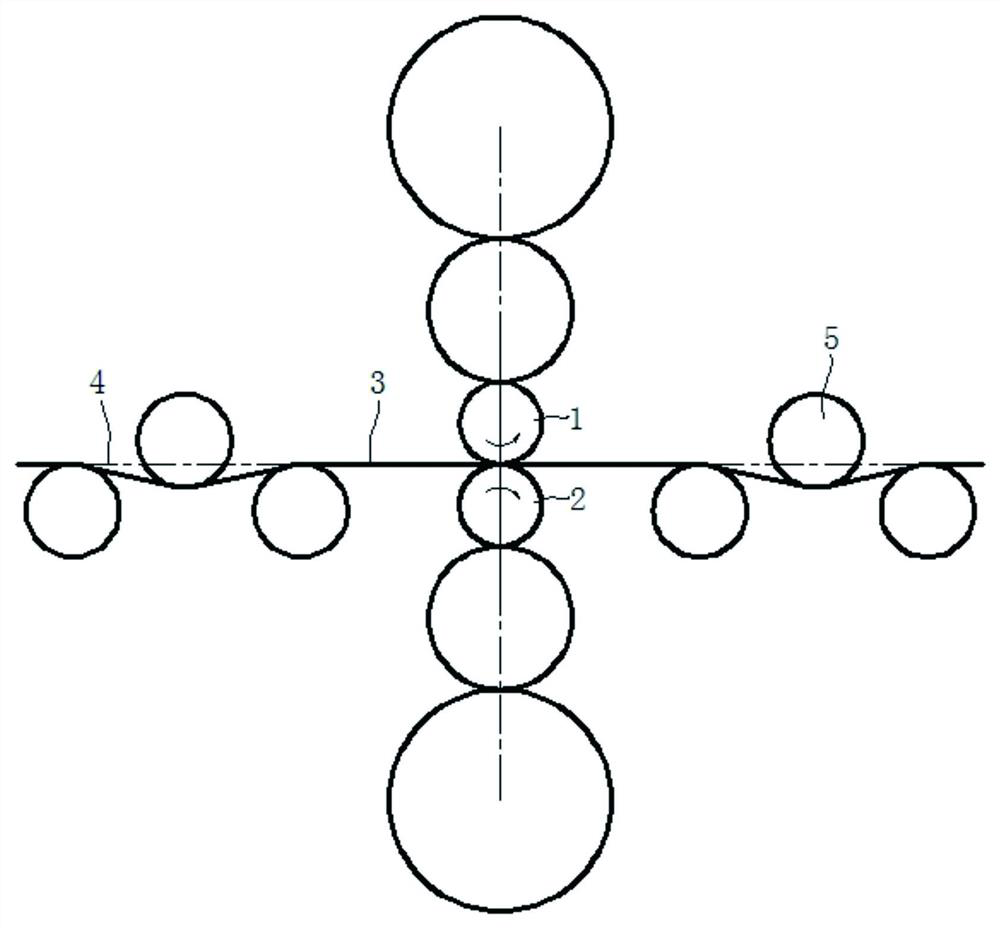

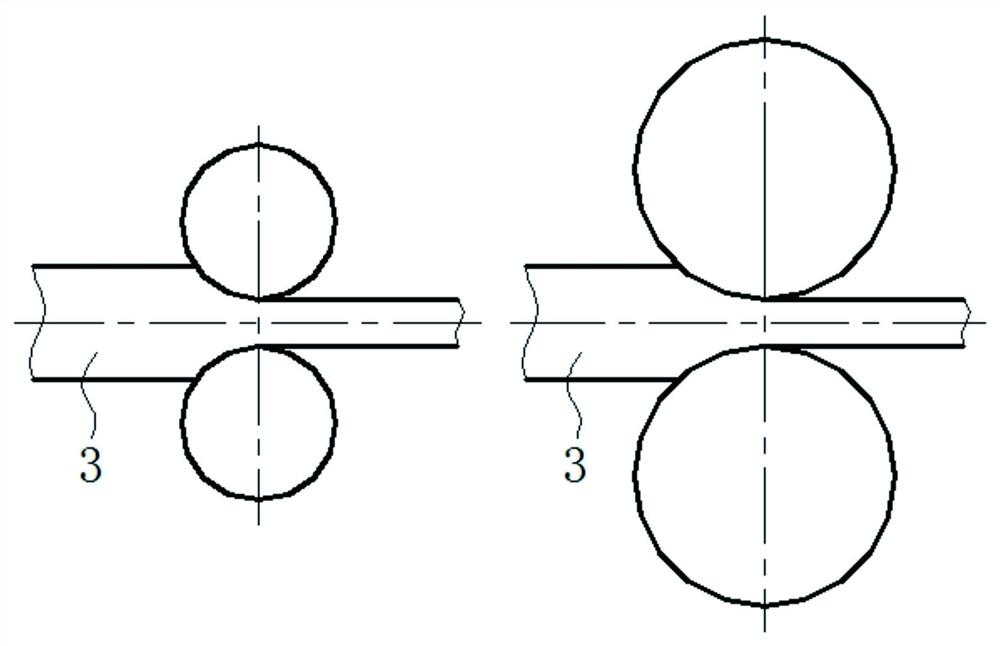

Method for setting process parameters of stainless steel strip steel withdrawal and straightening machine unit

The invention relates to a method for setting process parameters of a stainless steel strip steel withdrawal and straightening machine unit. The method is characterized in that a set of systemic method for setting the process parameters of a stainless steel withdrawal and straightening machine is established by utilizing finite element software to establish a simulation model and applying the stepwise regression principle to set the process parameters such as insertion depths and tension values of a 1# roller, a 2# roller and a 3# roller of a withdrawal and straightening machine, and optimization is achieved by combining application effects of actual production. By means of the method, defects of a wave plate shape and a warping plate shape easily occurring in the production of thinner stainless steel strip steel are eliminated well, theoretical guidance and technical support are provided for withdrawal and straightening of stainless steel, and quality of strip steel is greatly improved. Besides, a process parameter query and addition system interface has strong visuality so that the production is scientific and systematic, and the problem that the process parameters of work shifts are different due to personal experience factors of operators is solved. An adding system guarantees that technical personnel can add process parameters capable of enabling strip steel to obtain good plate shapes after a series of statistics according to actual conditions, so that a database can be kept updated frequently, and process parameter setting can be improved and optimized continuously. Therefore, the method for setting the process parameters of the stainless steel strip steel withdrawal and straightening machine unit has a wide application prospect.

Owner:NINGBO BAOXIN STAINLESS STEEL

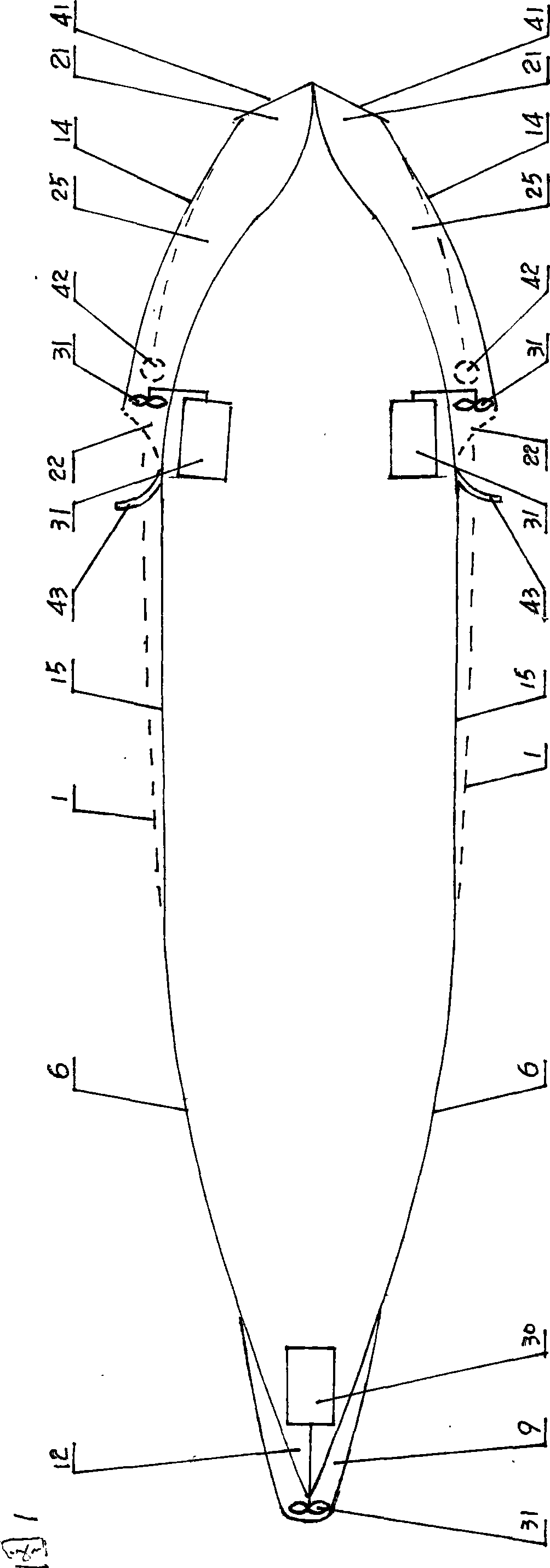

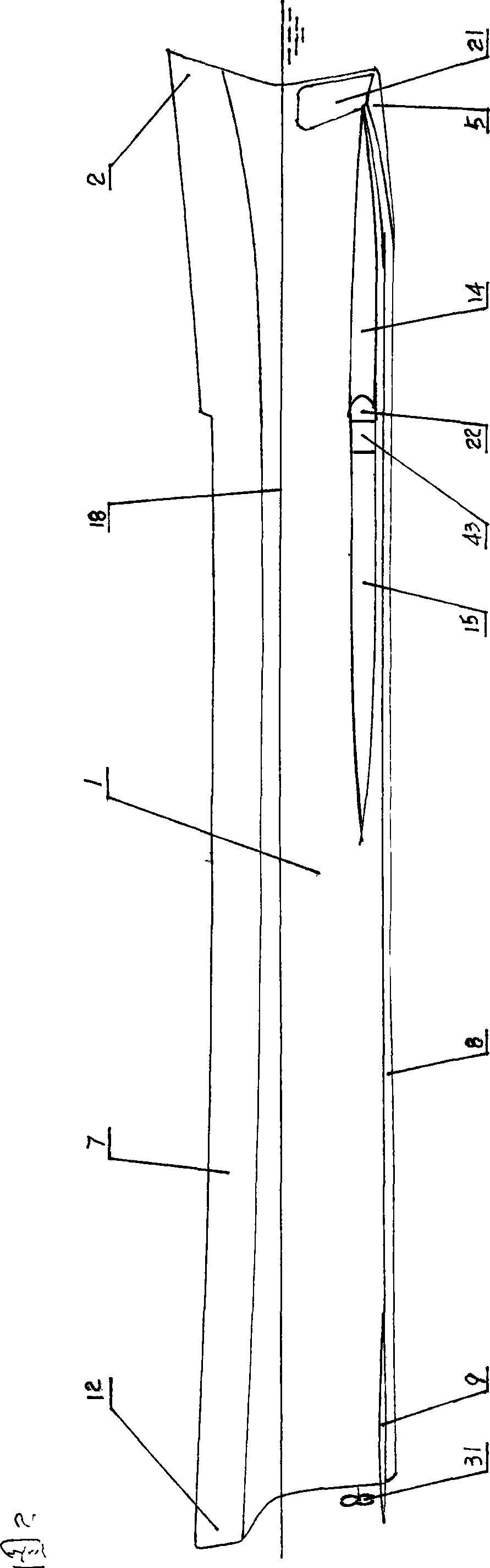

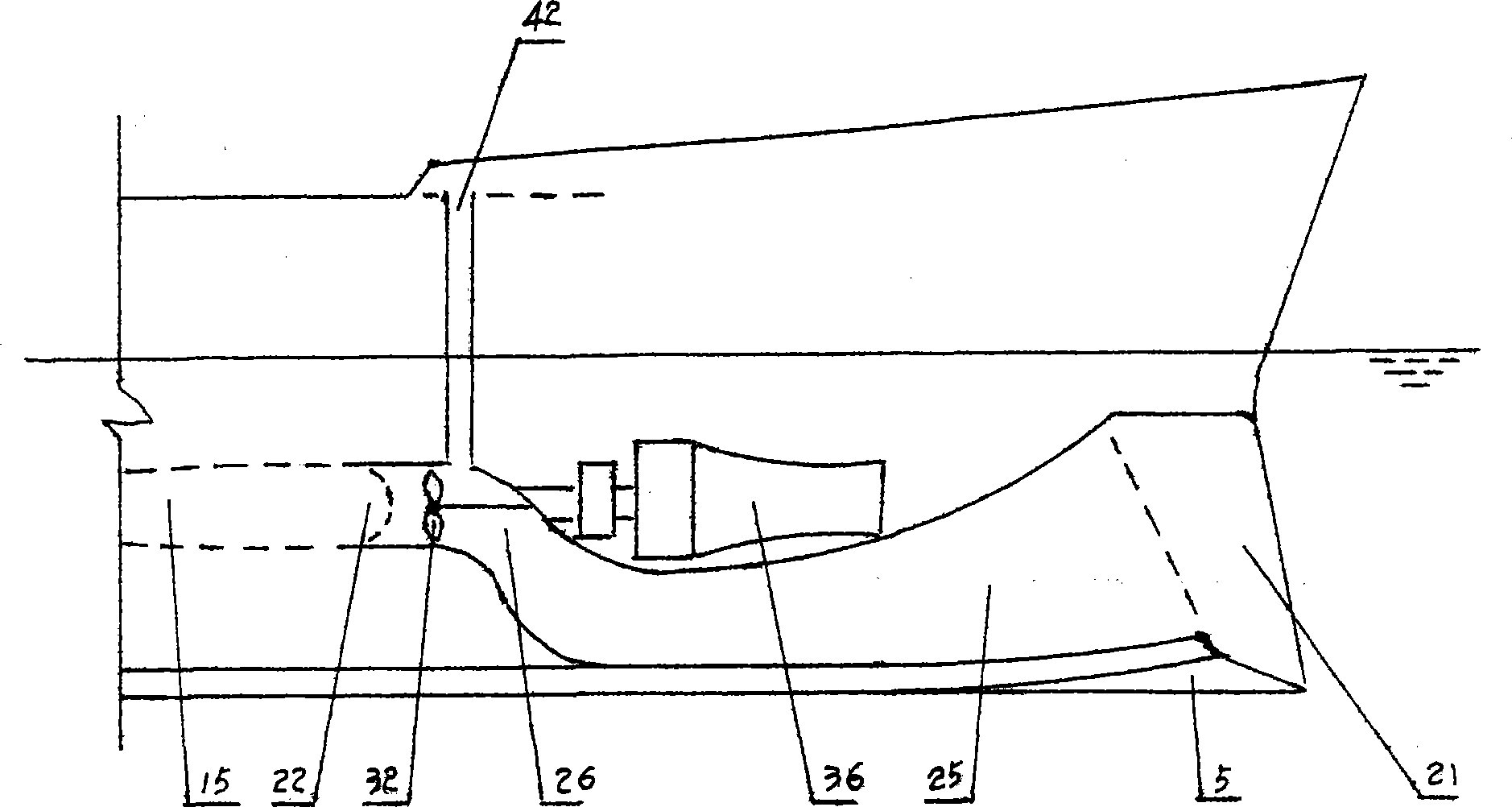

Marine promoted by front water

ActiveCN101386334AEliminate wavesEliminate wave resistanceWatercraft hull designPropulsive elementsImpellerWater channel

The present invention discloses a front water diversion propulsion ship and aims at providing a regular water diversion type ship which can eliminate wave making completely or reduce the wave making and eliminate wave making resistance and can also reduce the friction resistance and motivate the hydrodynamic propulsion to improve the comprehensive performance of the ship such as speed, stability and efficiency. The front water diversion propulsion ship is realized by a technical proposal as follows: a forward water inlet is arranged under the water line at the front part of the ship; and a backward water outlet or a thruster inlet are arranged and matched at the forward water inlet with a flow passage which runs through the forward water inlet and a stern or arranged at two lateral parts. Or a forward-backward thruster is arranged under the water line, or a watercourse is matched and arranged in the front of the water line, two lateral water outlets which are propelled by two sides of the front of the ship or propelled by a stern impeller are arranged, or the back ship body of the thruster is arranged as a streamline after run to motivate the hydrodynamic propulsion. The technology of the front water diversion propulsion ship can fit for designing and manufacturing a powered regular drainage ship and improving the existing ship and is especially fit for designing, manufacturing and improving the economical, large and jumbo ships.

Owner:赵富龙

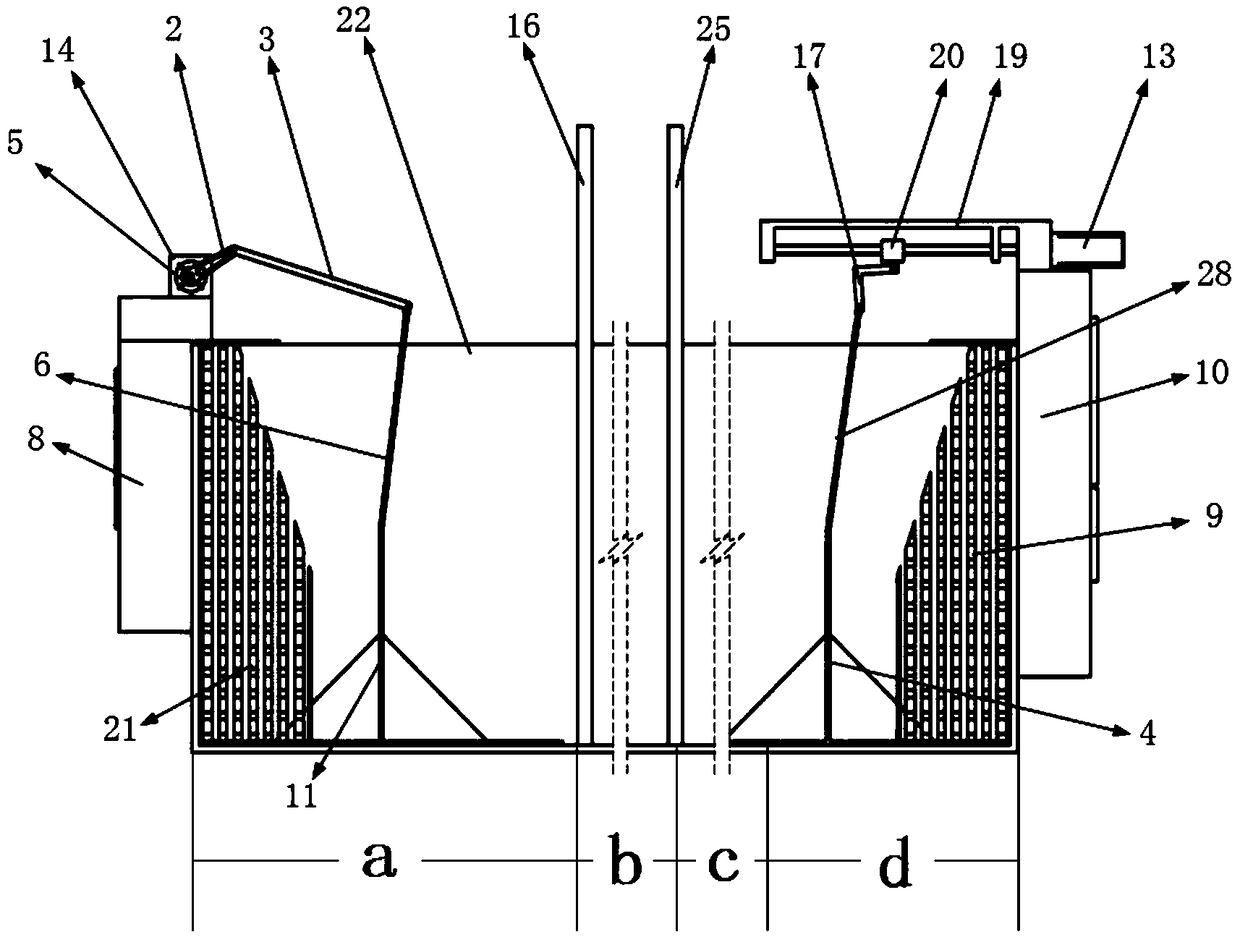

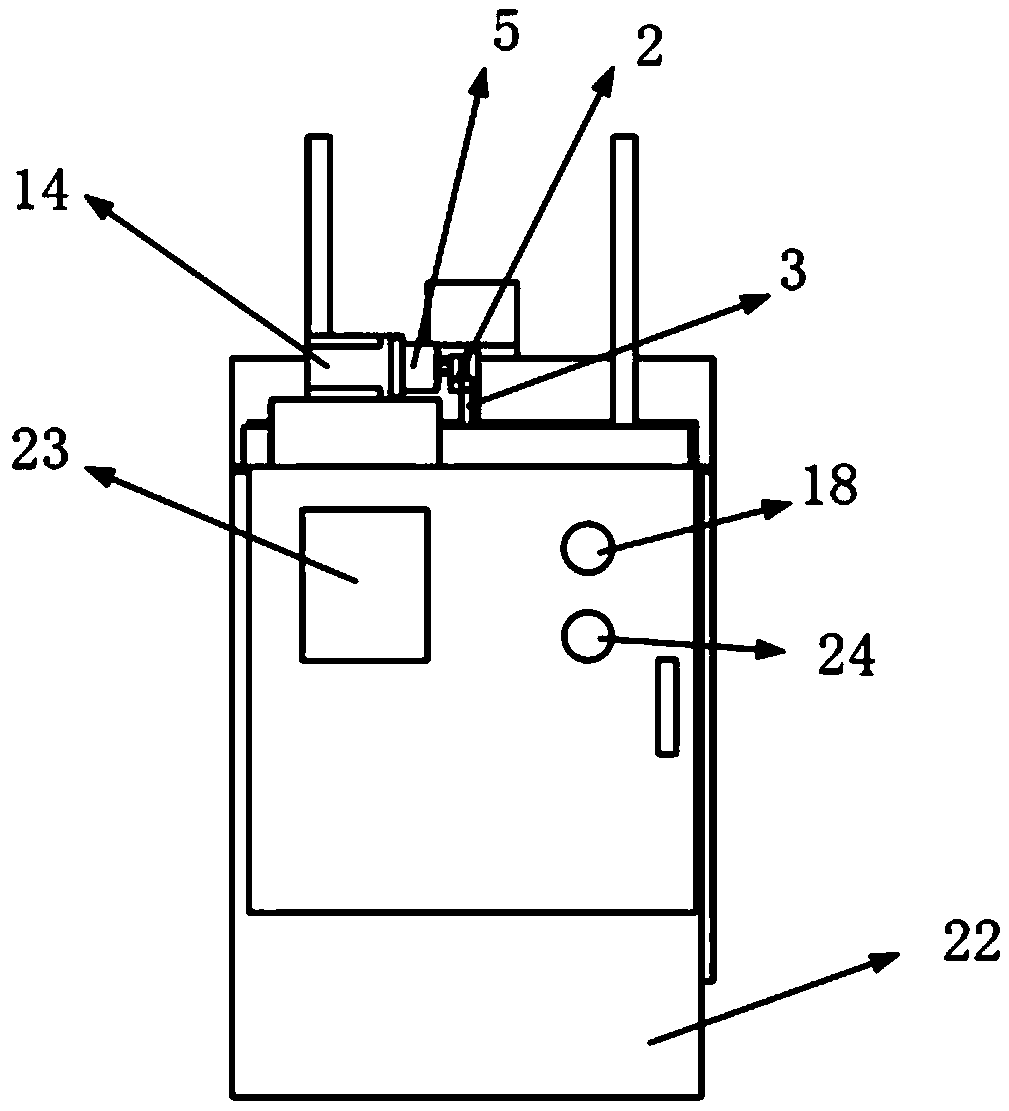

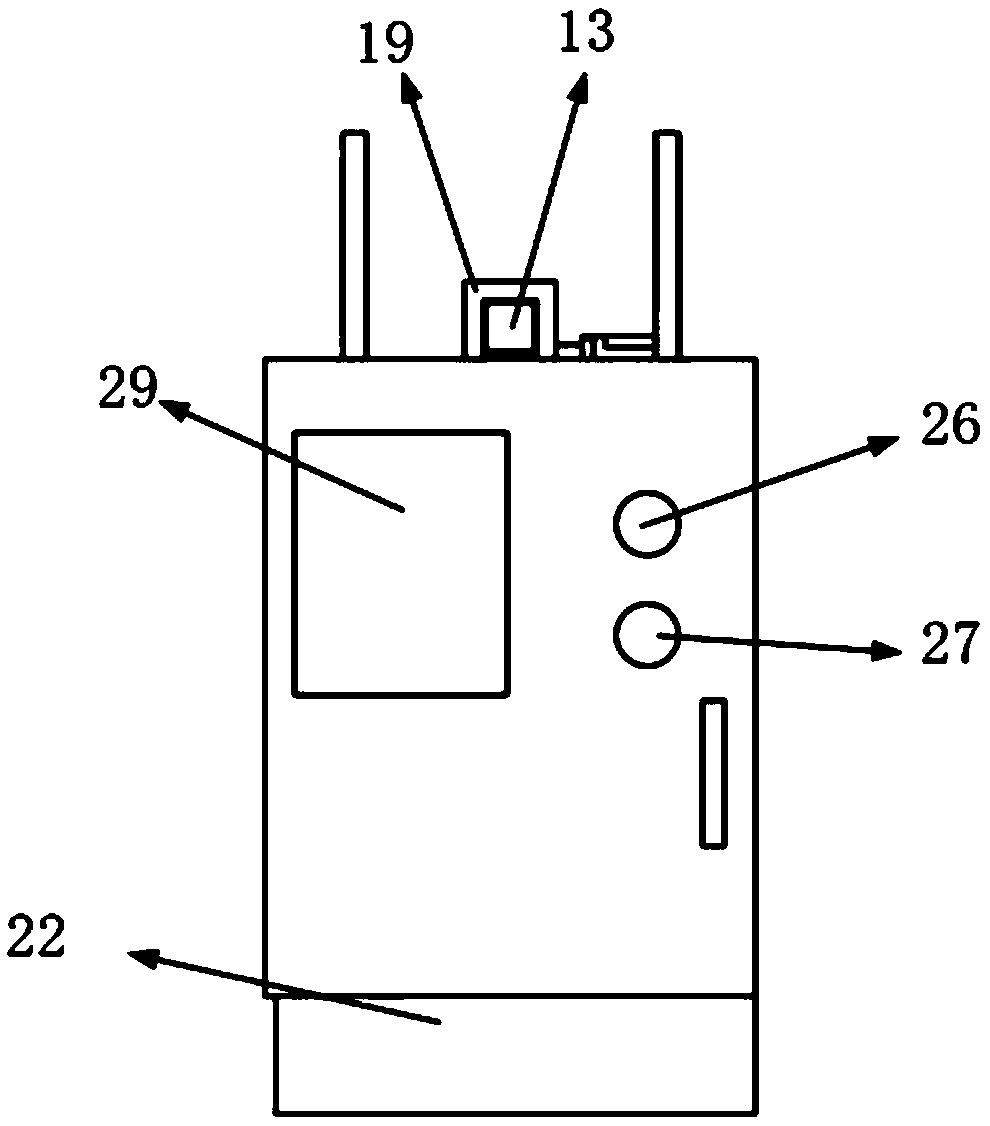

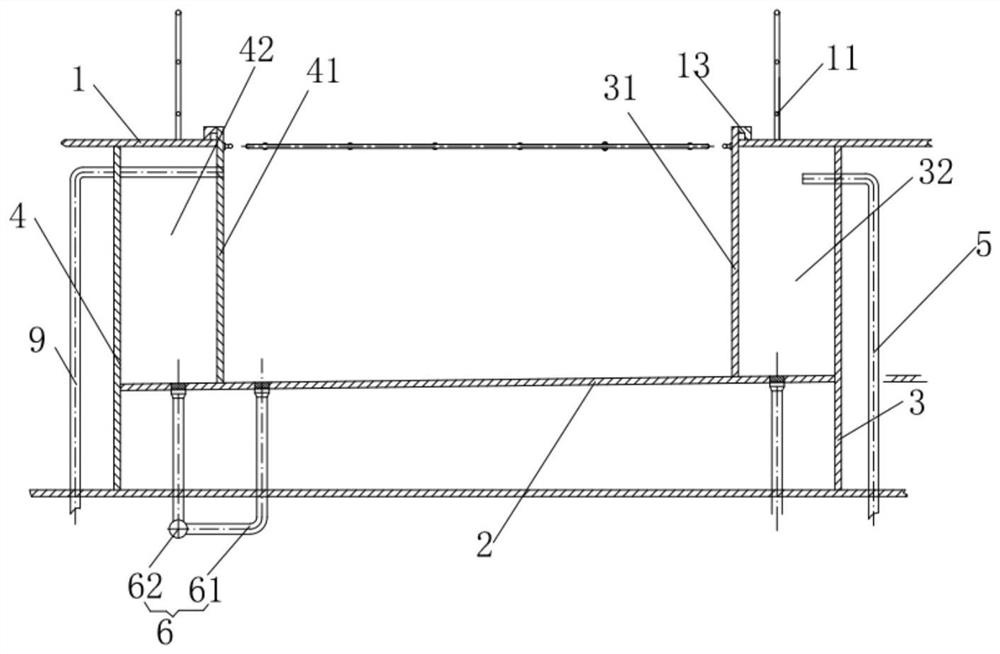

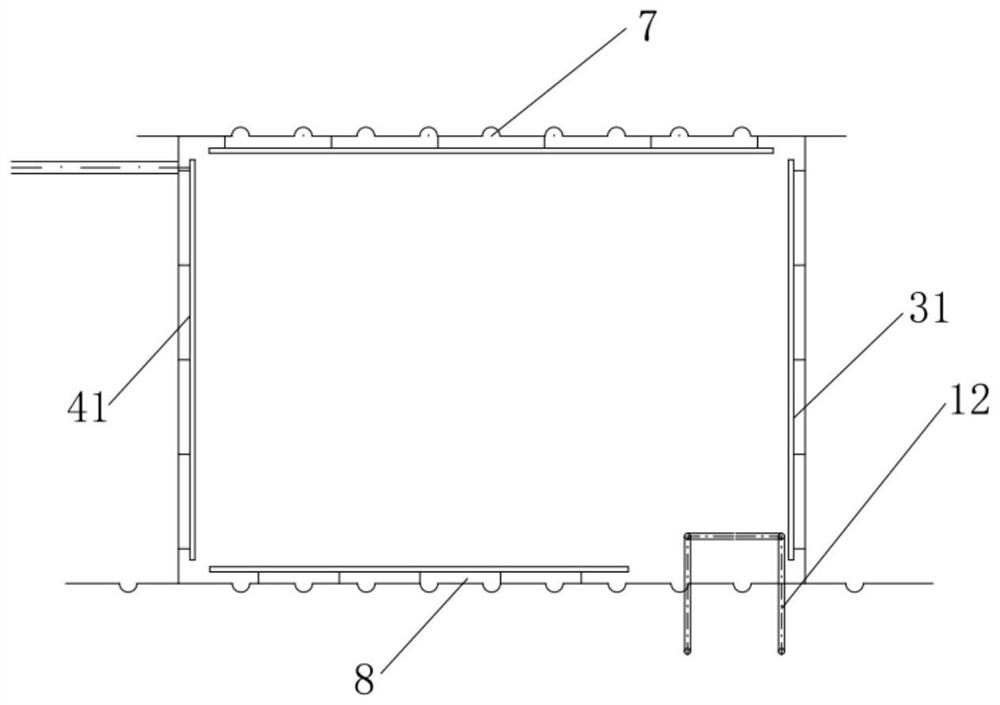

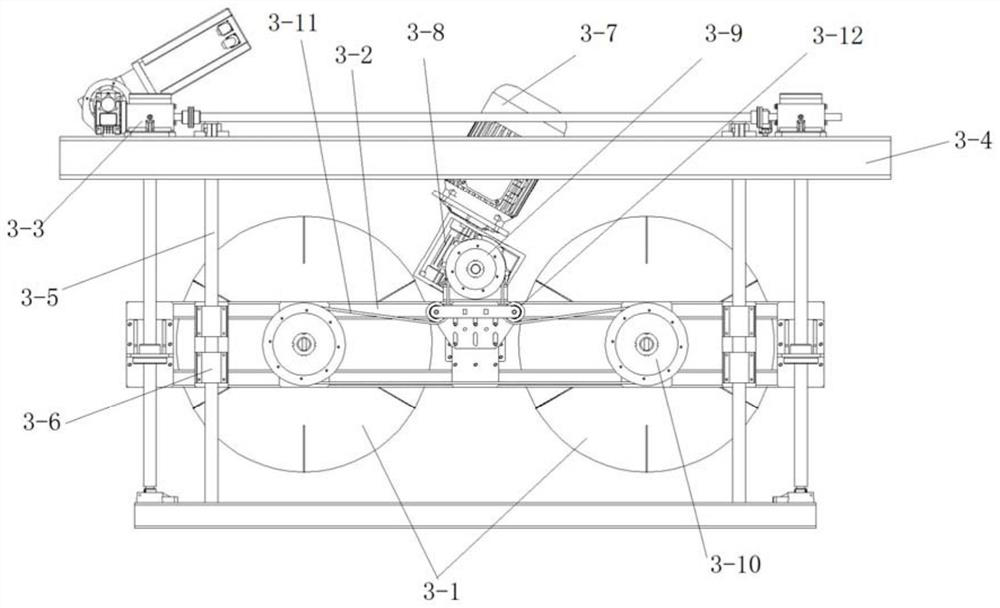

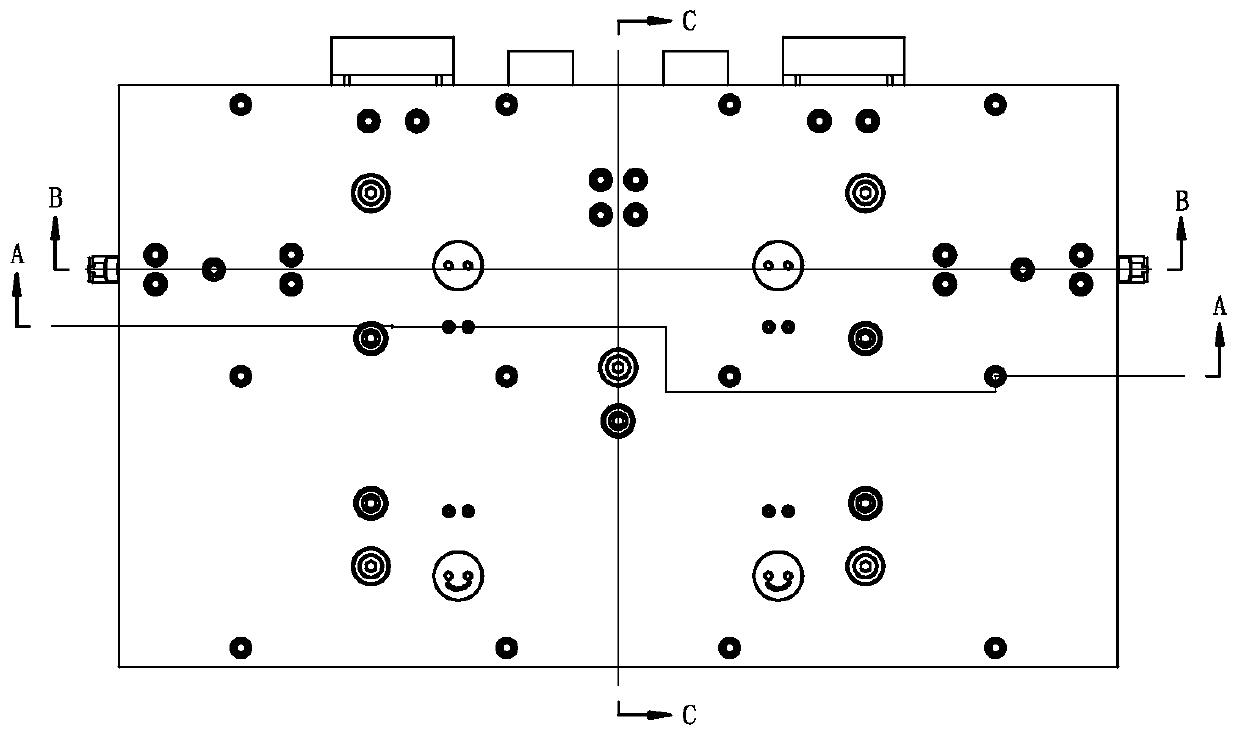

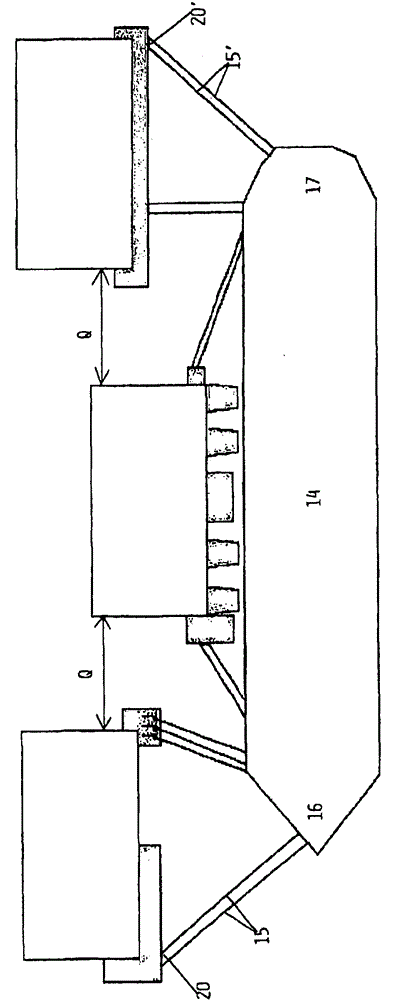

Intelligent wave generating water channel with active feedback wave elimination function

PendingCN109060298ASmooth runningEasy power adjustmentHydrodynamic testingActive feedbackControl system

The invention provides an intelligent wave generating water channel with an active feedback wave elimination function. The intelligent wave generating water channel comprises a wave generating deviceand a wave elimination device. The wave generating device comprises an active wave generating control system, a crank connecting rod mechanism and a wave generating swing plate. The active wave generating control system is connected with the crank connecting rod mechanism through a wave generating servo motor. The crank connecting rod mechanism is connected with the wave generating swing plate. The wave elimination device comprises an active wave elimination control system, a lead screw mechanism and a wave elimination swing plate. The active wave elimination control system is connected with the lead screw mechanism through a wave elimination servo motor, and the lead screw mechanism is connected with the wave elimination swing plate. The intelligent wave generating water channel further comprises an active wave generating measuring instrument and an active wave elimination measuring instrument which are arranged in the water channel and connected with the active wave generating control system and the active wave elimination control system correspondingly. The intelligent wave generating water channel is small in structure size, high in operability, high in wave quality, good in stability, easy to control and the like and has extremely-high application value and popularization value.

Owner:HARBIN ENG UNIV

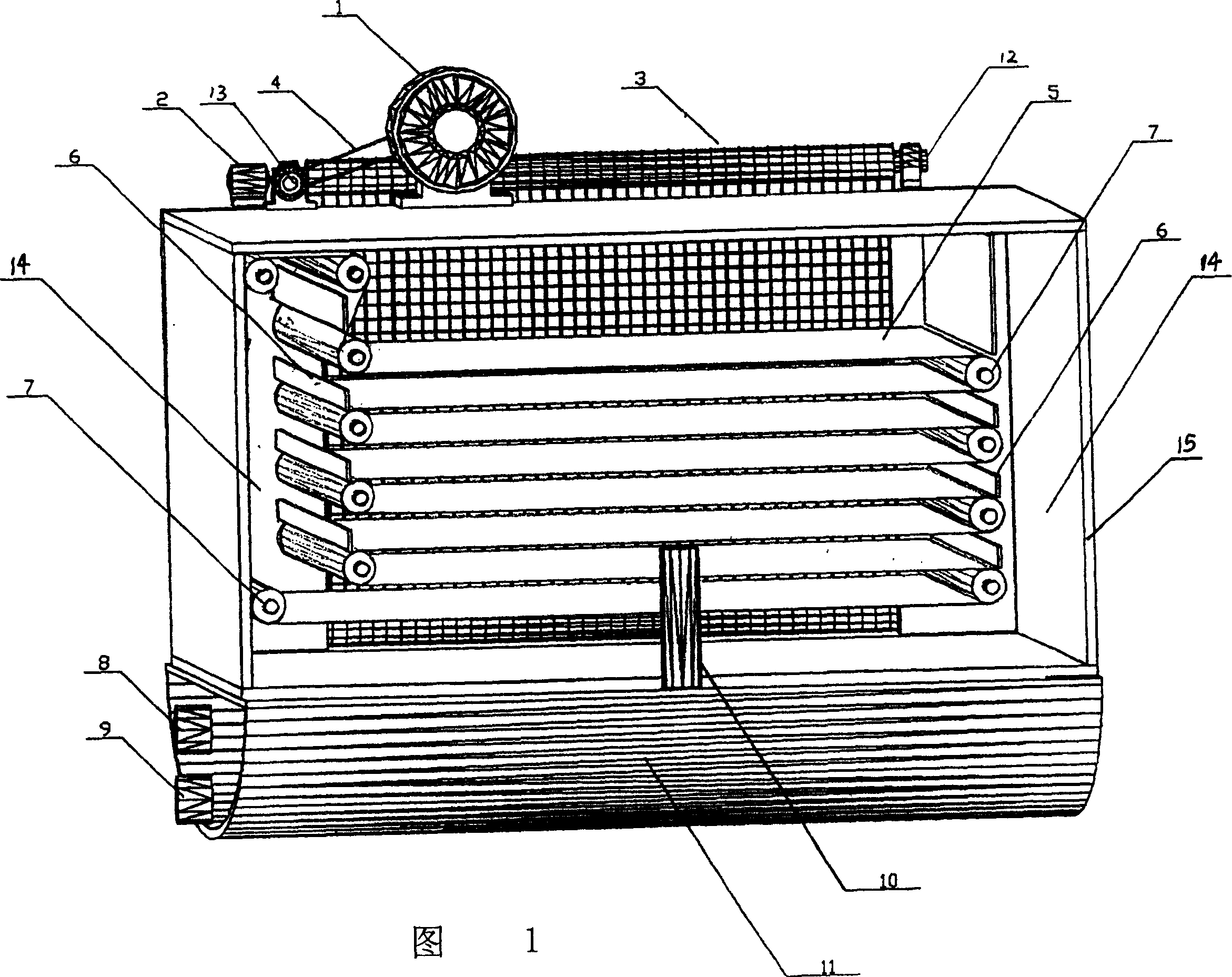

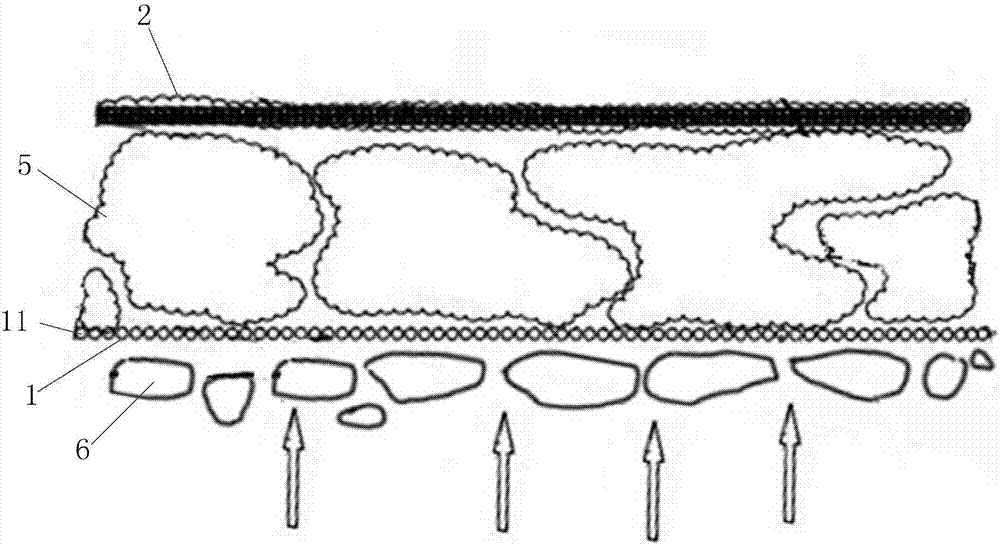

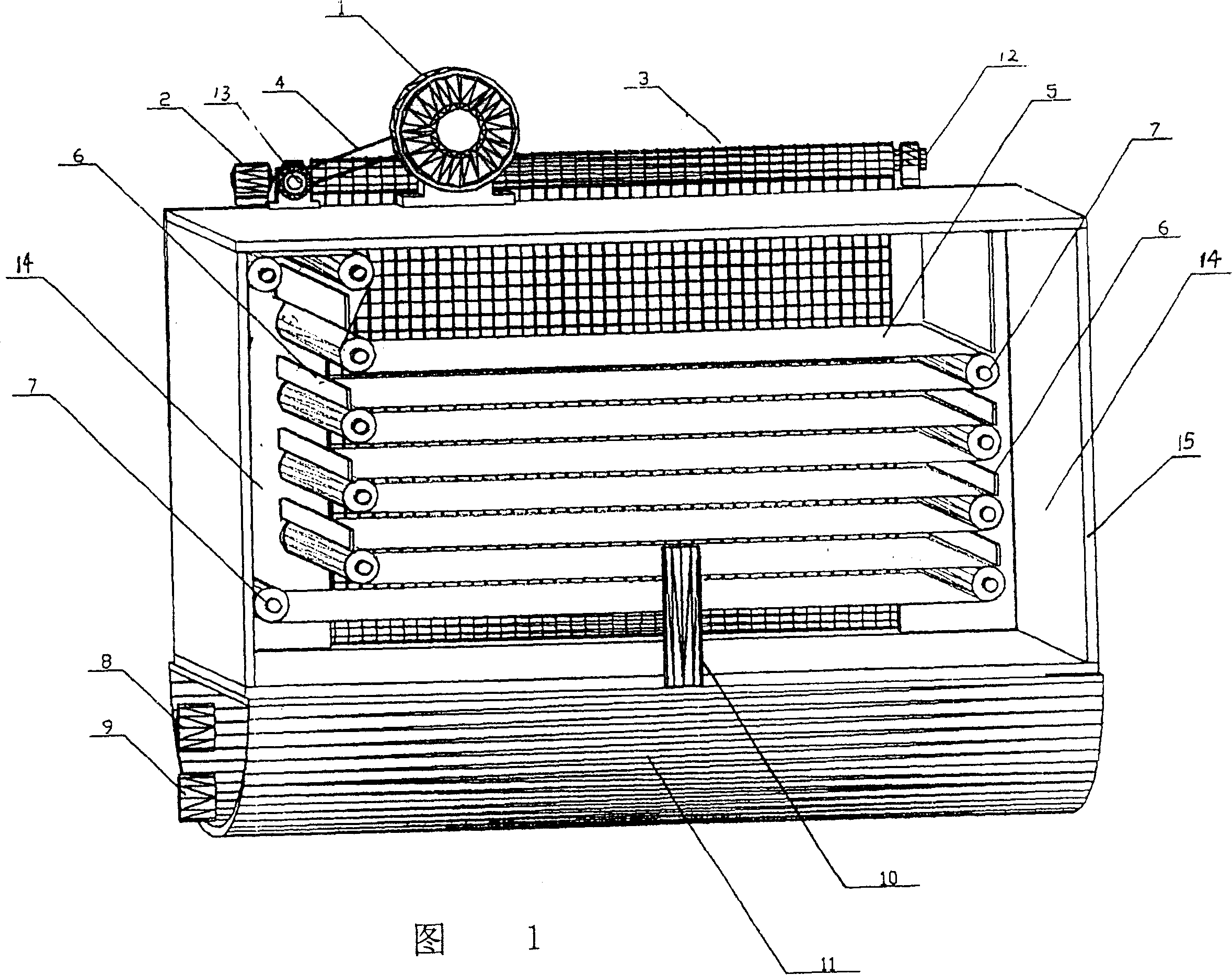

Process and apparatus for enriching aquatic micro algae

InactiveCN1597922APromote enrichmentEasy to captureUnicellular algaeHarvestersEngineeringSewage treatment

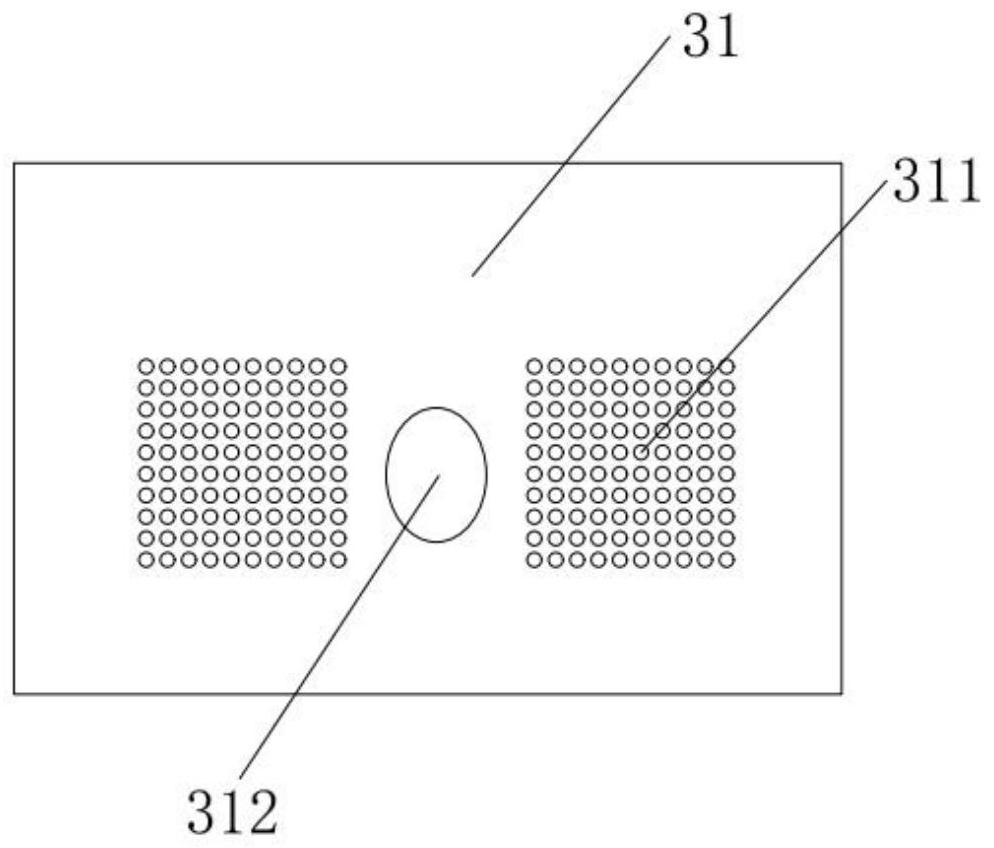

The invention relates to a water-body microalgae enriching method and device, especially a wave-canceling multilayer microalgae enriching method and device, limiting water body for collecting microalgae in a algae collecting tank with baffle plates on two sides, residues blocking net at the front end and a notch at the back end, installing annular inflective, layered and flexible tape in the tank, driving by electric motor to move each layer of microalgae nearby the baffle plates for enriching, and then pumping away the microalgae. The invention has simple device structure, high alage obtaining efficiency, and low energy consumption and is not affected by wind and wave as working in a large-scale natural water body.

Owner:KUNMING UNIV OF SCI & TECH

Plant for storage and unloading hydrocarbon and also a method thereof

This publication discloses a harbour plant (10) for storage, loading and unloading of hydrocarbon products at sea, comprising a number of units (9) being mutually placed on the seabed so that a harbour plant is formed. The units (9) are placed independently at a given distance apart in sideways direction and having a front surface along which a vessel is intended to be moored, forming passage(s) for parts of the waves, and being configured to dampen a part of the incoming waves while allowing other parts of the waves and current to pass through the harbour plant. The sideways distances between two neighbouring units (9) is governed by the frequency of the waves to be dampened and the frequencies of the waves allowed to pass in between the units (9). The front surface of one of the units (9) is offset with a distance relative to the front surfaces of two neighbouring in a traverse direction away from said incoming waves, and / or that the units are configured in such way that the width of the passage between two neighbouring units increases or decreases in direction of the wave motion.

Owner:GRAVIFLOAT AS

Method for setting process parameters of stainless steel strip steel withdrawal and straightening machine unit

The invention relates to a method for setting process parameters of a stainless steel strip steel withdrawal and straightening machine unit. The method is characterized in that a set of systemic method for setting the process parameters of a stainless steel withdrawal and straightening machine is established by utilizing finite element software to establish a simulation model and applying the stepwise regression principle to set the process parameters such as insertion depths and tension values of a 1# roller, a 2# roller and a 3# roller of a withdrawal and straightening machine, and optimization is achieved by combining application effects of actual production. By means of the method, defects of a wave plate shape and a warping plate shape easily occurring in the production of thinner stainless steel strip steel are eliminated well, theoretical guidance and technical support are provided for withdrawal and straightening of stainless steel, and quality of strip steel is greatly improved. Besides, a process parameter query and addition system interface has strong visuality so that the production is scientific and systematic, and the problem that the process parameters of work shifts are different due to personal experience factors of operators is solved. An adding system guarantees that technical personnel can add process parameters capable of enabling strip steel to obtain good plate shapes after a series of statistics according to actual conditions, so that a database can be kept updated frequently, and process parameter setting can be improved and optimized continuously. Therefore, the method for setting the process parameters of the stainless steel strip steel withdrawal and straightening machine unit has a wide application prospect.

Owner:NINGBO BAOXIN STAINLESS STEEL

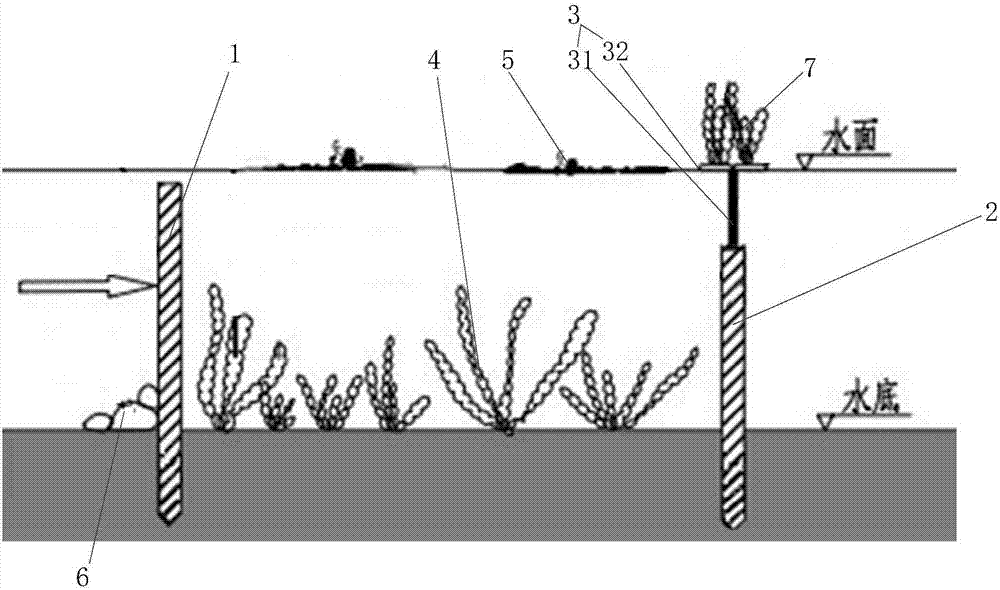

Three-stage protective screen ecological wall

ActiveCN107381941AEnsure normal flowReduce flowWater resource protectionBiological treatment apparatusEcological environmentThree stage

The invention relates to a three-stage protective screen ecological wall, and relates to the field of ecological environment engineering. The invention mainly adopts a technical scheme that the three-stage protective screen ecological wall comprises a first protective screen, a second protective screen, a third protective screen and a biomimetic wall body, wherein the bottom of the first protective screen is inserted into submarine mud, and the distance from the top of the first protective screen to the perennial low water level of shallow-water rivers and lakes is 10-20cm; the second protective screen comprises potamogeton crispus and water chestnuts; the bottom of the third protective screen is inserted into submarine mud, the top of the third protective screen is 30-50cm lower than the top of the first protective screen, a predetermined distance is reserved between the third protective screen and the first protective screen, and the second protective screen is arranged between the first protective screen and the third protective screen; the biomimetic wall body comprises a plurality of artificial water plants and a plurality of floating beds in predefined specifications; one end of each artificial water plant is connected with the top of the third protective screen, the other end of each artificial water plant is connected with the corresponding floating bed, and a plurality of floating beds float on the water surface. The three-stage protective screen ecological wall disclosed by the invention can reduce stormy waves of rivers and lakes, and can increase the transparency of water bodies at the same time.

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI

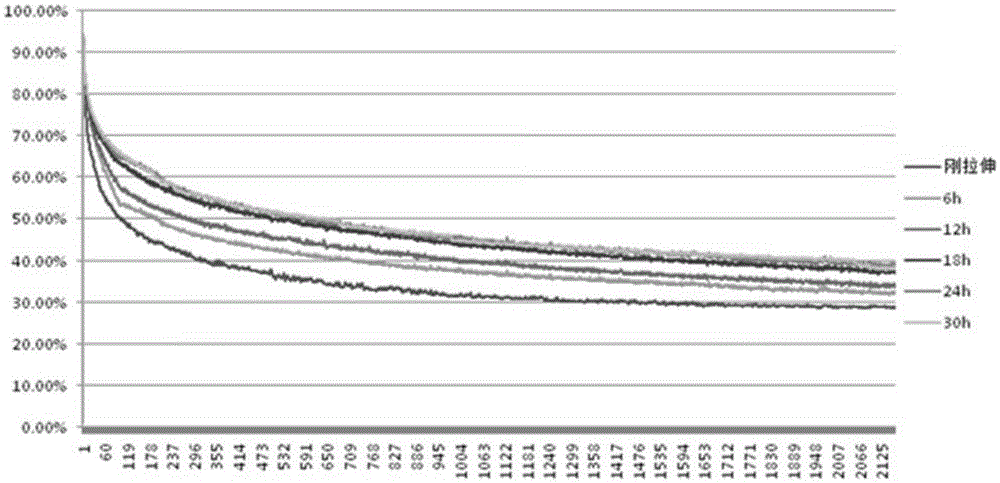

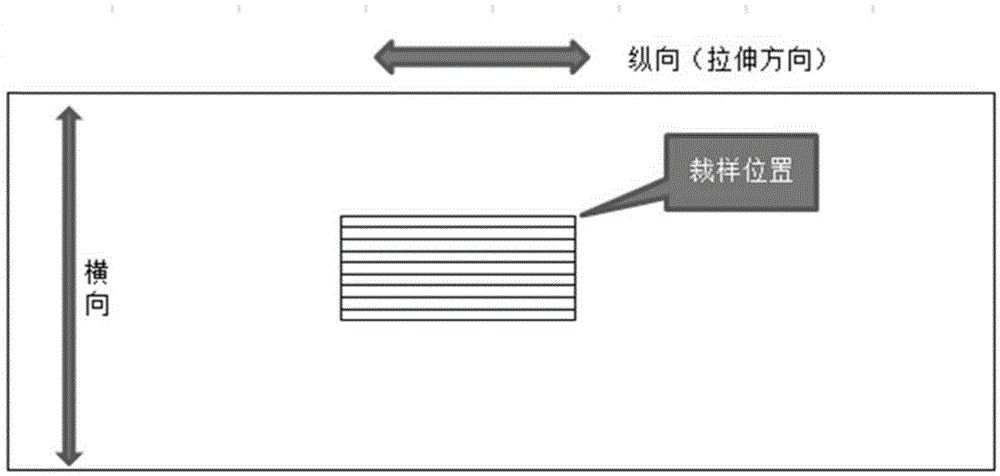

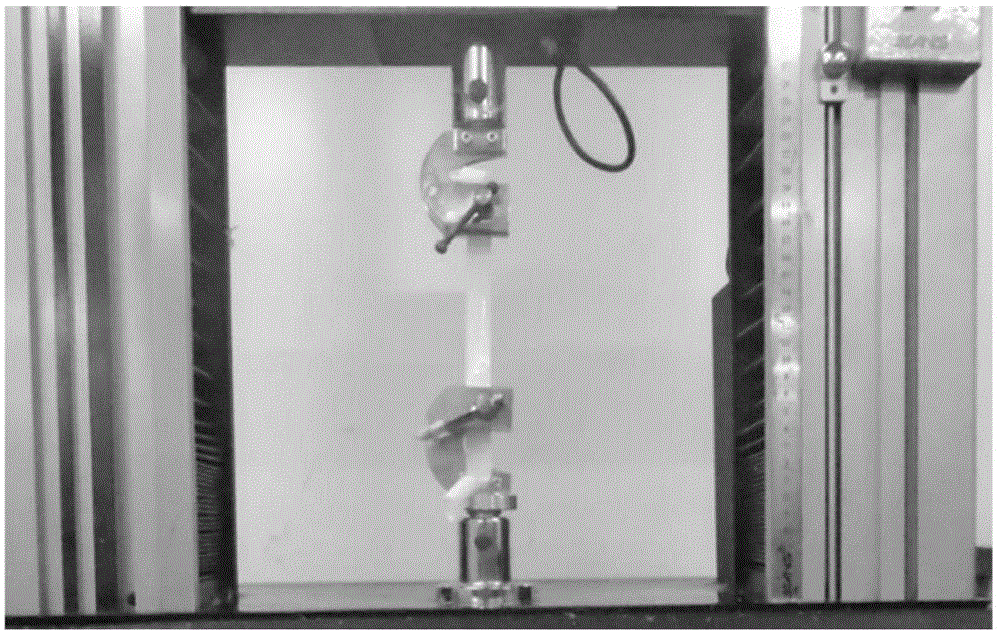

Method for detecting service life of tensioned dry method uniaxial tension diaphragm

InactiveCN105352804ASimplify the inspection processImprove efficiencyMaterial strength using tensile/compressive forcesCell component detailsProcess engineeringEngineering

The invention mainly aims at providing a method for detecting the service life of a tensioned dry method uniaxial tension diaphragm. Bases are provided for the actual production process, and waves, tippets and other later changes in the diaphragm production process are reduced. A tensile testing machine is adopted. According to the method for detecting the service life of the tensioned dry method uniaxial tension diaphragm, the tensile testing machine is adopted, the bases are provided for the actual production process, and the situation that waves, tippets and other later changes are caused in the diaphragm production process due to the fact that placing time is insufficient is avoided.

Owner:SHENZHEN SENIOR TECH MATERIAL

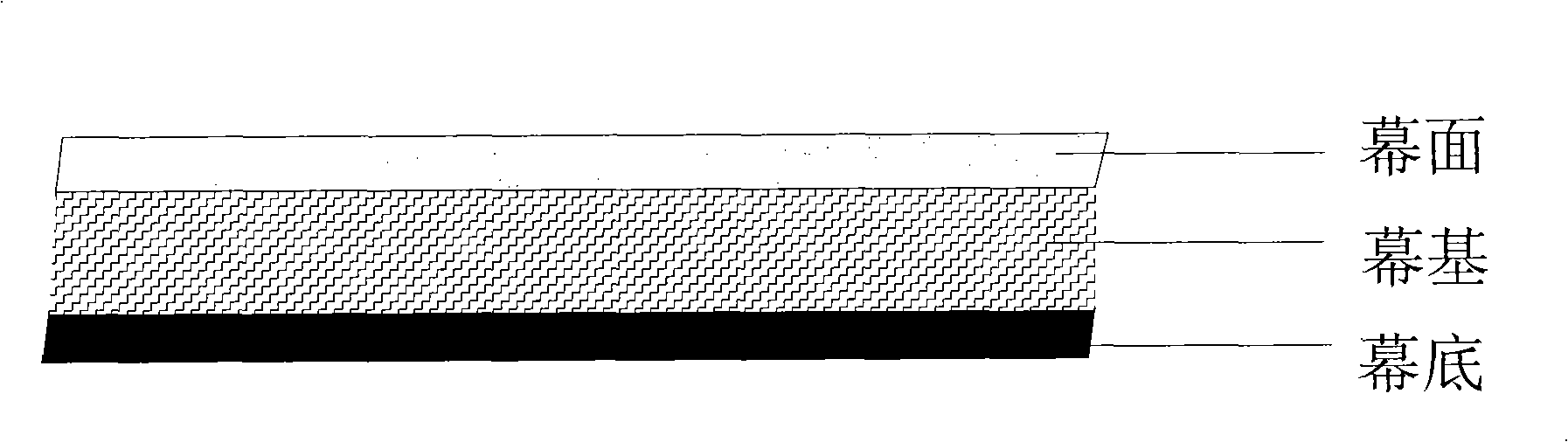

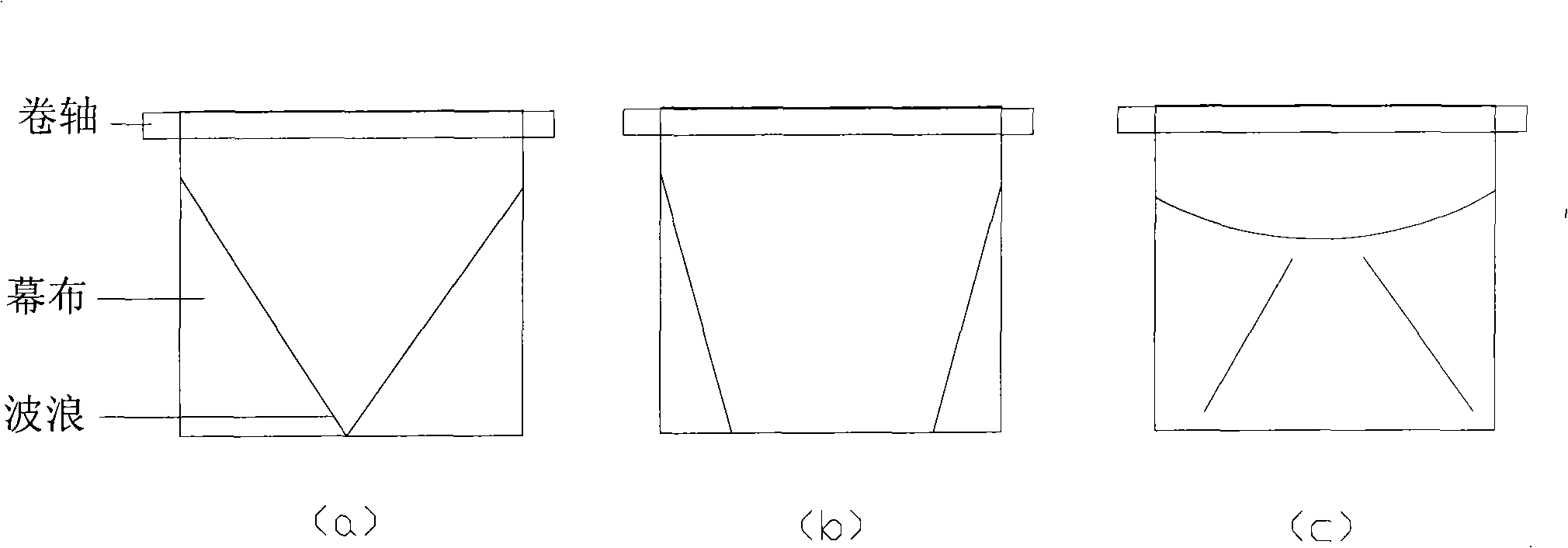

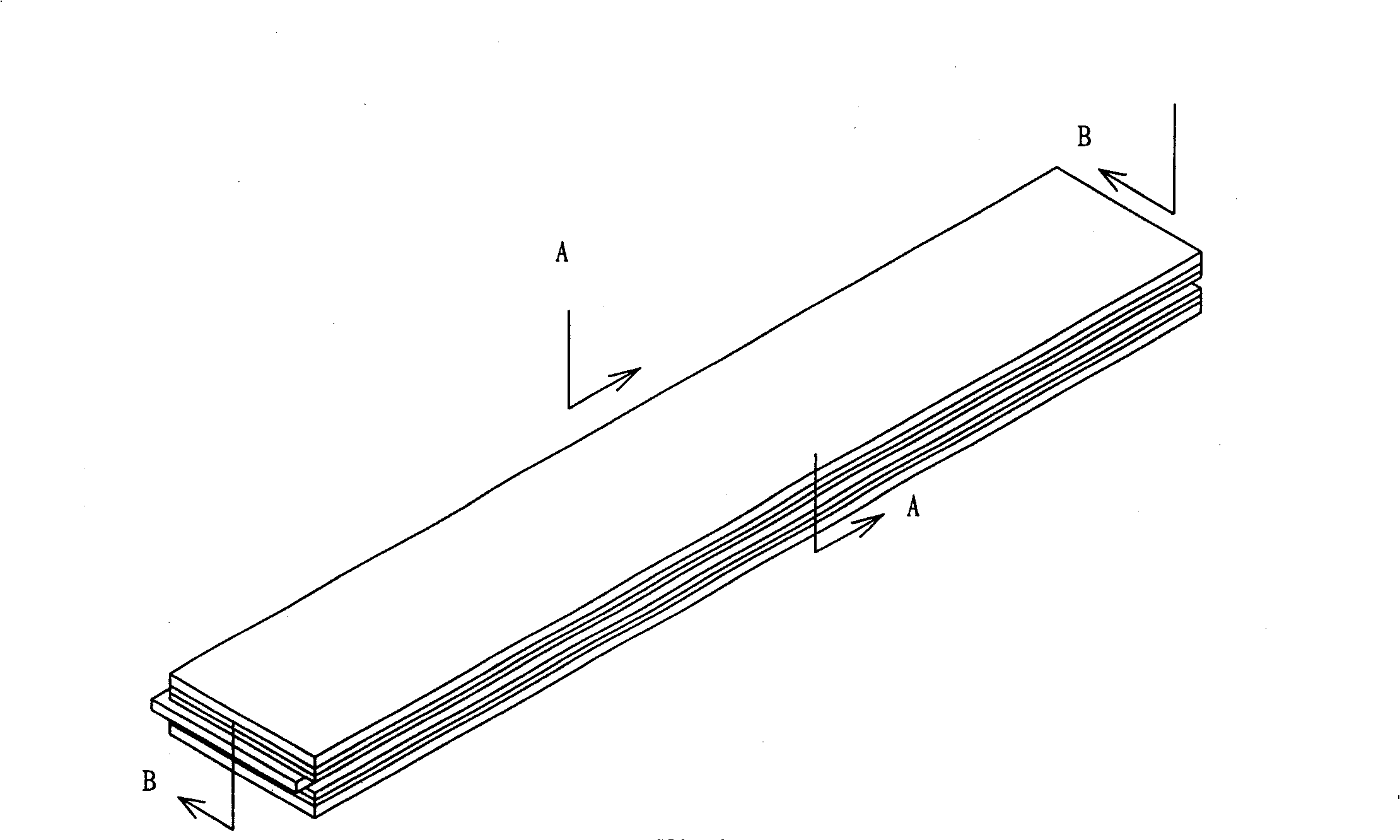

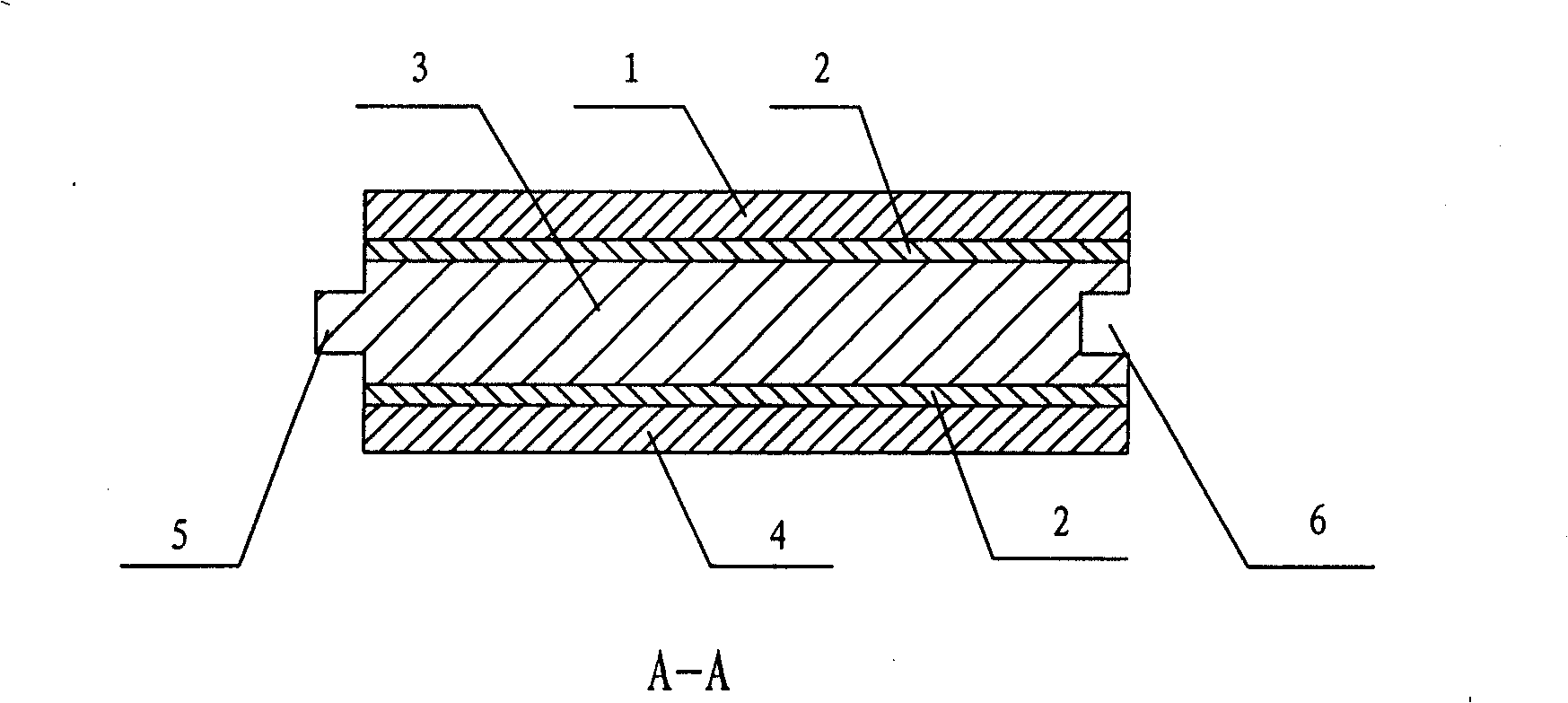

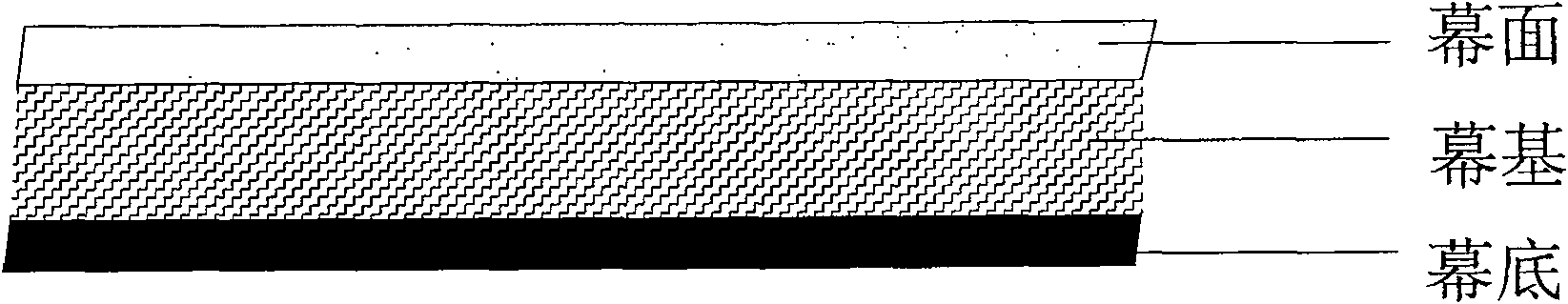

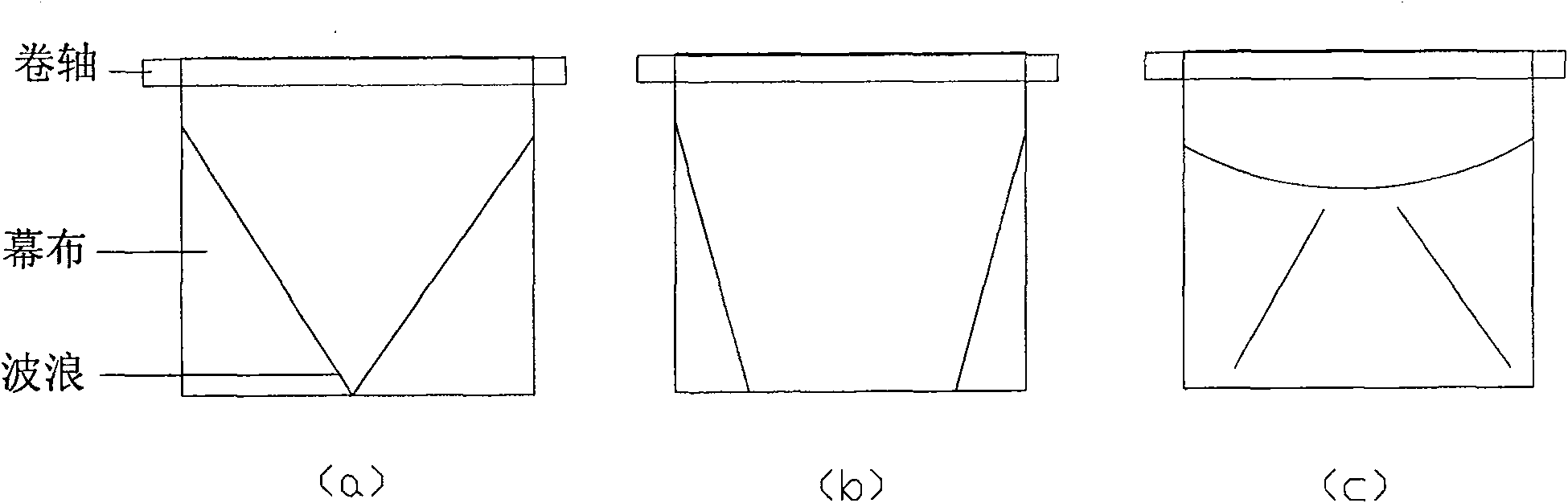

Special type veil base

The invention discloses a translucent screen, wherein, a screen base of the screen takes the structure of a plurality of layers or two layers and the layers of the screen base adhere to each other by adhesive materials. Because the concave and the convex formed by curliness of the screen for a long term can be stretched to be straight under the action of gravity after the screen is hung and unfolded and the local deformation of any screen base layer can be constrained by other layers, the breadth for fluctuation of the screen can be greatly reduced and then V-shaped waves are difficult to occur in the screen of the technical proposal, thereby the problem of smoothness of the translucent screen is well solved.

Owner:罗筱泠

Swimming pool system for ship

The invention relates to the technical field of ships, in particular to a swimming pool system for a ship, the swimming pool system comprises a first coaming and a second coaming which are arranged on a lower deck at an interval along the extension direction of the ship; a first side plate and a second side plate which are arranged on the lower deck at an interval; a first partition plate, wherein a plurality of first through holes are formed in the first partition plate at intervals; the first partition plate and the first surrounding plate are arranged in the swimming pool cavity in a spaced mode, and the first partition plate, the first side plate and the second side plate are connected to form a first partition cavity; a water supply assembly, wherein a water inlet of the water supply assembly is located in the first partition cavity; and a drainage assembly which is communicated with the swimming pool cavity. Waves accumulated along with shaking of the main ship body in the swimming pool can be eliminated, and sailors can normally swim in the swimming pool under conventional sea conditions.

Owner:GUANGZHOU SHIPYARD INTERNATIONAL LTD

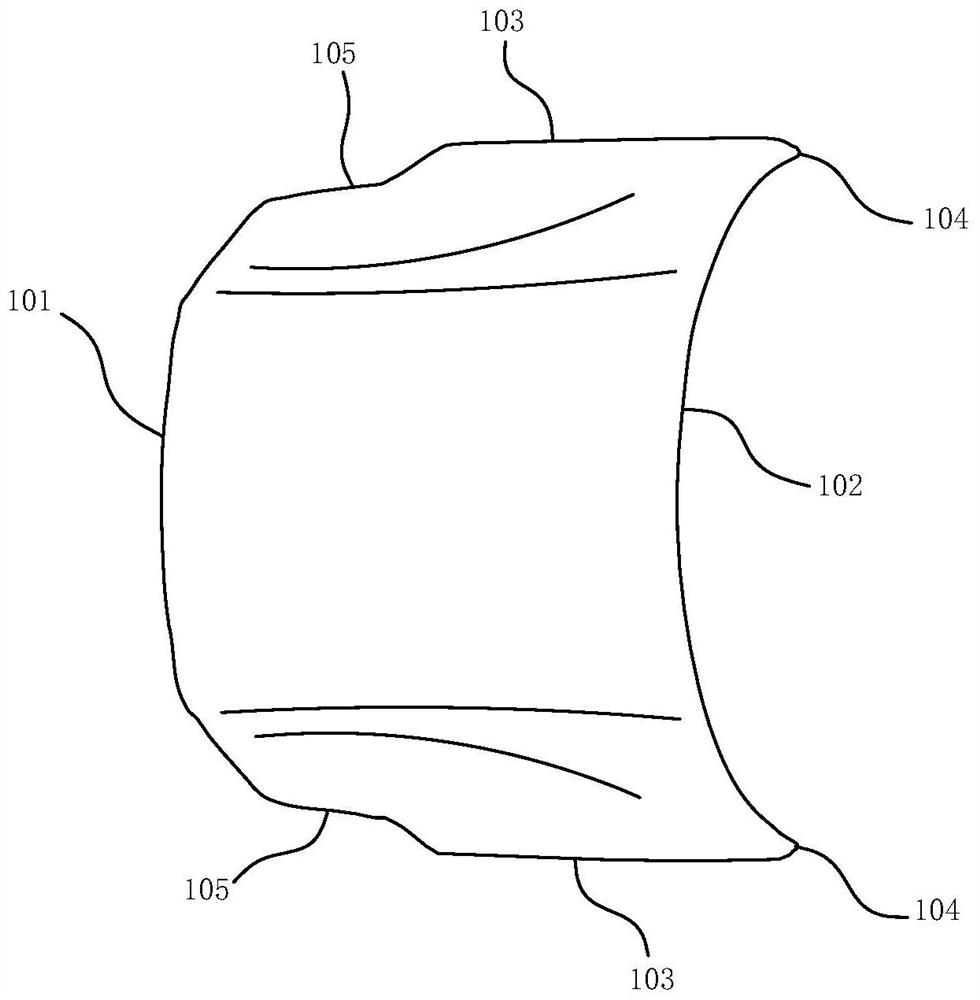

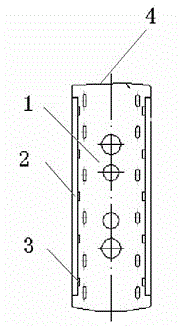

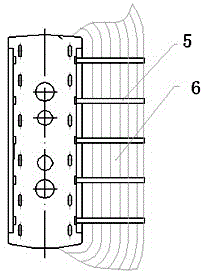

Iron core winding core die for transformer with wound stereoscopic triangular iron core

ActiveCN103280309AQuality improvementEasy transitionTransformers/inductances detailsInductances/transformers/magnets manufactureTransformerMaterials science

The invention discloses an iron core winding core die for a transformer with a wound stereoscopic triangular iron core. The iron core winding core die comprises a body, iron bars separable from the body are arranged on two sides of the body, and a group of windows used for binding core limbs is arranged at the joint of the inner side of the iron bars and the body. The upper and lower end faces of the body are provided with radian. Iron chips wound by the core die are compact and non-wavy, and the iron core winding core die in combined structure facilitates binding and shaping of the core limbs after annealing, and iron core quality is greatly improved.

Owner:JIANG SU ZHONGRONG TECH

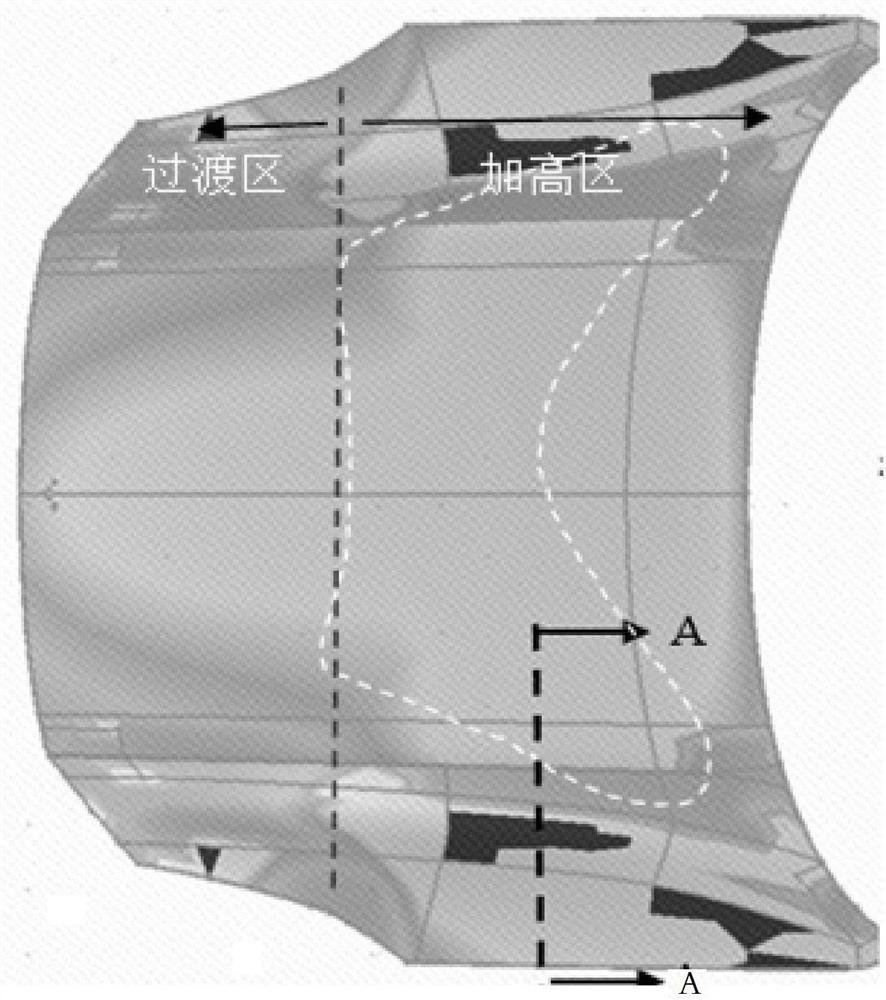

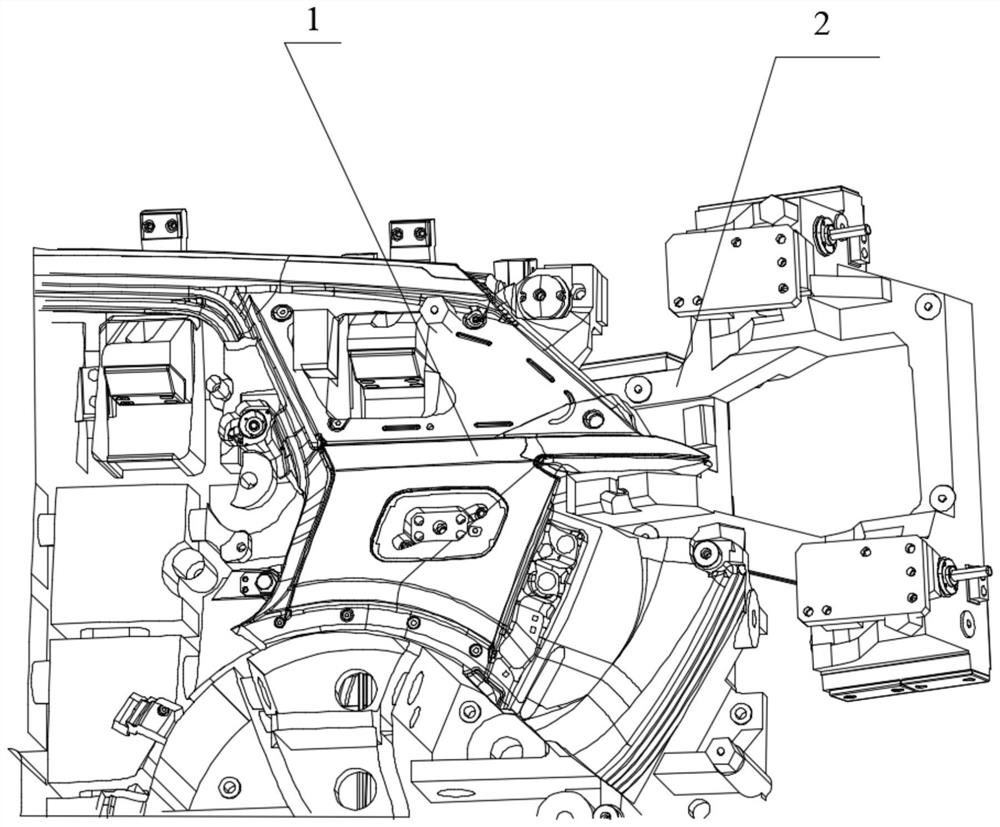

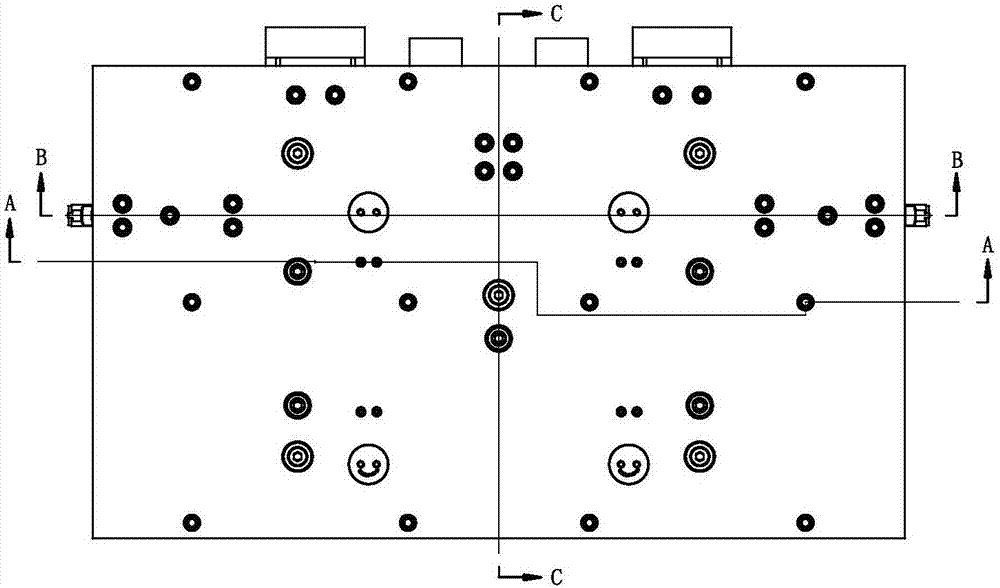

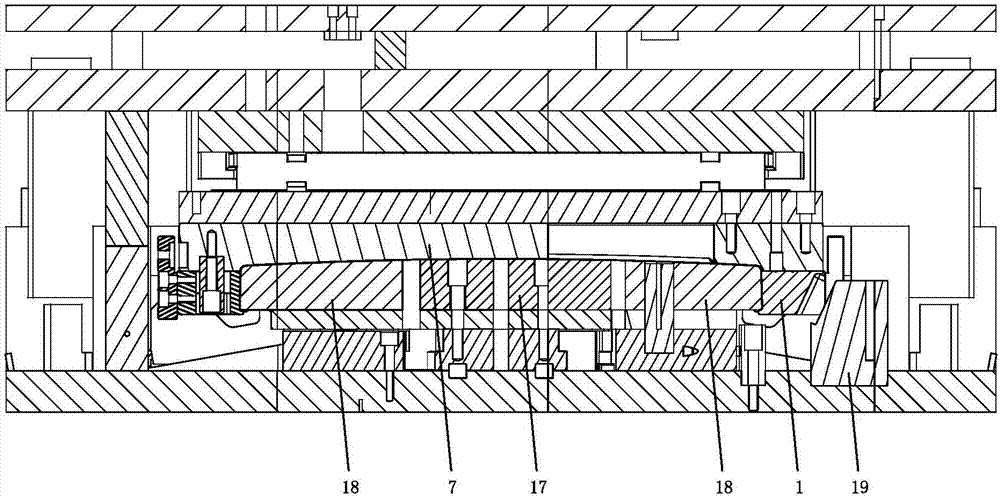

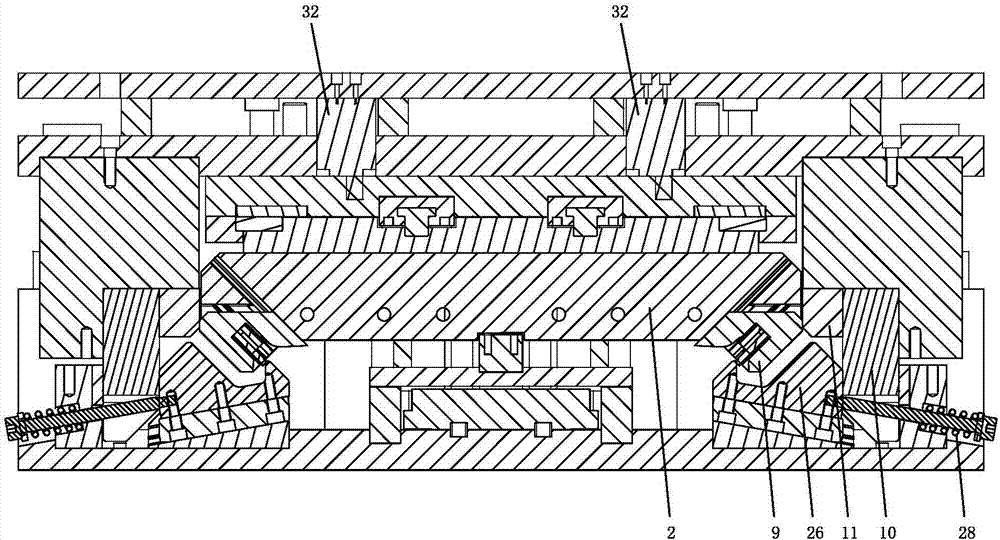

Rebound control method of engine hood outer plate, flanging die and vehicle

PendingCN114871336AImprove assembly accuracyImprove appearance qualityShaping toolsVehicle componentsMechanical engineeringTransverse shear

The invention relates to the technical field of vehicle body forming, in particular to a springback control method of an aluminum engine hood outer plate, a flanging die and a vehicle. The method comprises the steps that a flanging male die and an upper material pressing plate are used for pressing the area, except the flanging area, of the engine hood outer plate; the flanging area on the engine hood outer plate is pressed tightly through a flanging female die and a full-circumference pressing plate, so that the flanging process of the flanging area of the engine hood outer plate is completed in the clamped state, and huge springback caused by transverse shear stress released by free flanging of an arc area is avoided. According to the scheme, the curvature radius is adjusted, the auxiliary ridges are arranged, and the height and range of the main ridges are increased; the springback amount is reduced to be within a manufacturing end risk controllable range, and the problem of waves near main ridges can be eliminated. The problem of huge springback generated in the industrialization stage of the aluminum engine hood can be solved, the assembly precision of the engine hood can be improved, the assembly gap is reduced, and the appearance quality of the whole vehicle is improved.

Owner:ZHEJIANG ZEEKR INTELLIGENT TECH CO LTD +1

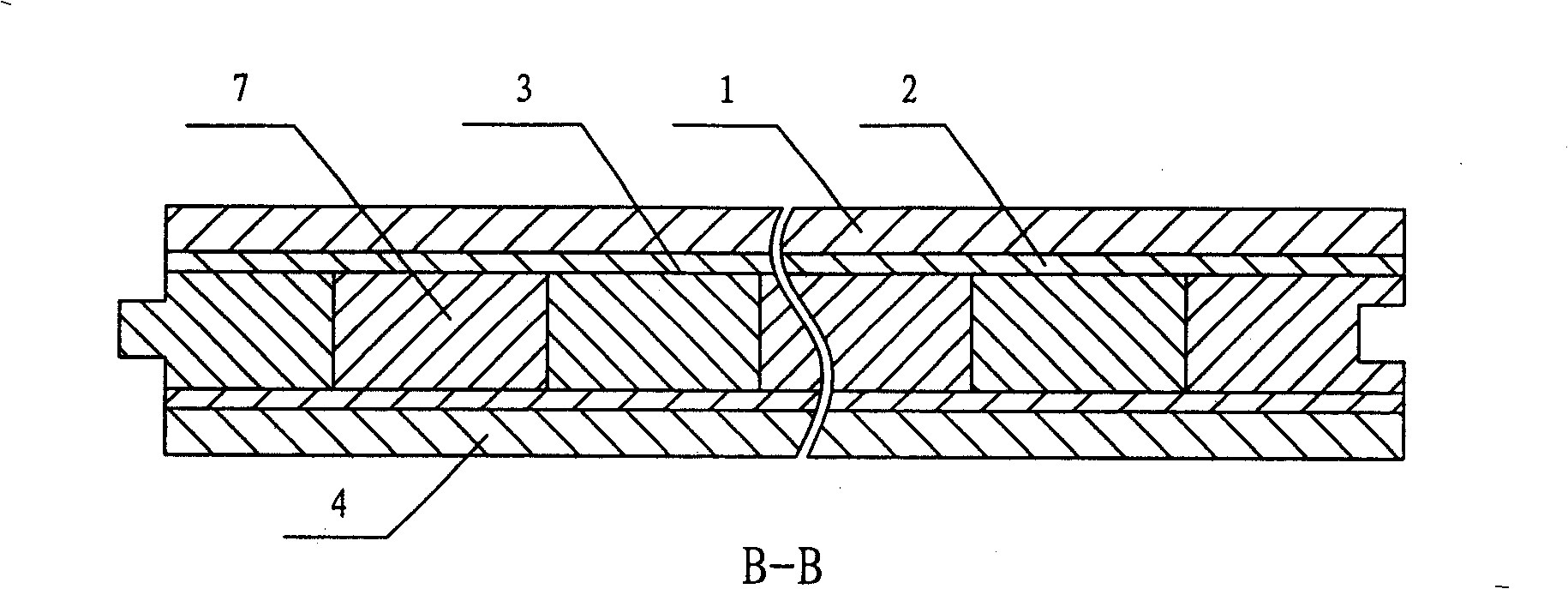

Five-layered thick core wood compound floor board and mfg. method thereof

InactiveCN100436734CStress constraintsAvoid deformationLaminationWood working apparatusSolid woodWood fibre

The present invention relates to one kind of five-layer thick-core wooden floor board and its making process. The five-layer thick-core wooden floor board includes one surface wood layer, one gummed sheet layer, one core layer, one other gummed sheet layer and one back layer adhered together successively. The making process of the five-layer thick-core wooden floor board includes the following steps: making surface wood board, making core layer board, making gummed sheet, making back board, combination and pressing, splitting and balancing, and forming. The five-layer thick-core wooden floor board of the present invention has the advantages of less deformation caused by environment temperature and humidity, reduced surface wood layer thickness resulting in saving in high quality wood, and raised adhesion strength and high stability.

Owner:上海新四合木业有限公司

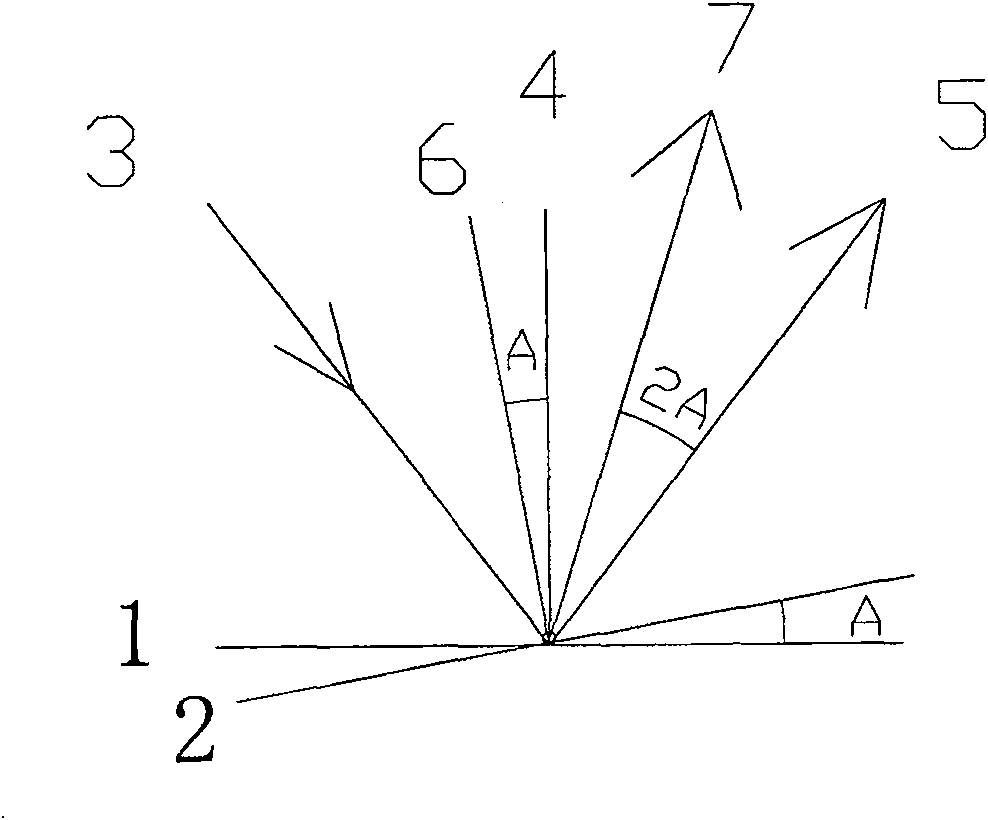

A submarine landslide physical model test device and working method

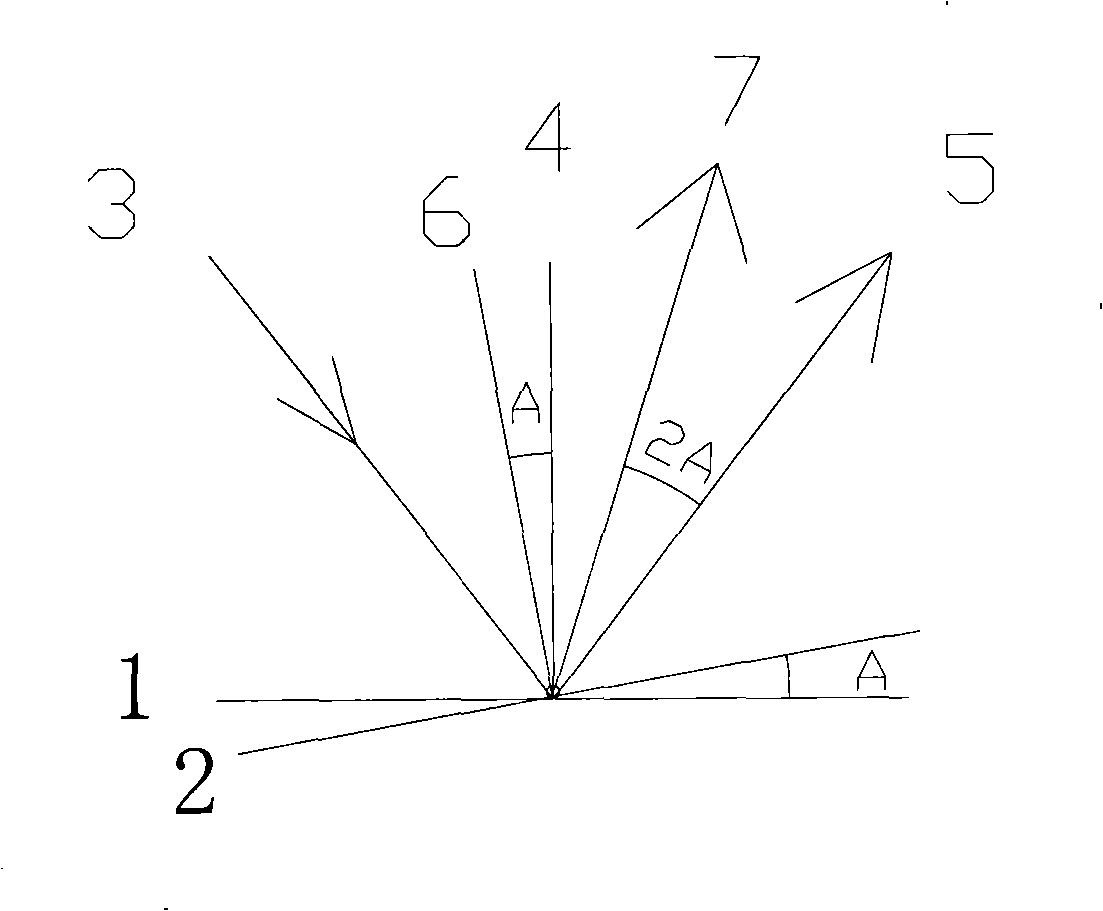

ActiveCN111076893BServe as a referenceEliminate wavesHydrodynamic testingEarth material testingGratingAcute angle

The present invention relates to a submarine landslide physical model test device and working method, comprising: a model box: a wave-making mechanism and a wave-dissipating mechanism are respectively arranged at both ends of the model box; The slide rail is slidingly connected with the wave-making box, the wave-making box is connected with the wave-making driving mechanism, and the side wall of the wave-making box on the side where the wave-dissipating mechanism is located is set at an acute angle with the horizontal plane; the wave-dissipating mechanism: includes at least one The wave-dissipating drum, the wave-dissipating drum is connected with the wave-dissipating driving mechanism; the monitoring mechanism: including multiple fiber grating sensors embedded in similar materials, multiple fiber grating sensors are connected in series with optical fibers, and the optical fibers are connected with the optical fiber regulator. The experimental device invented is of great significance to the study of submarine landslides.

Owner:POWERCHINA HUADONG ENG COPORATION LTD +1

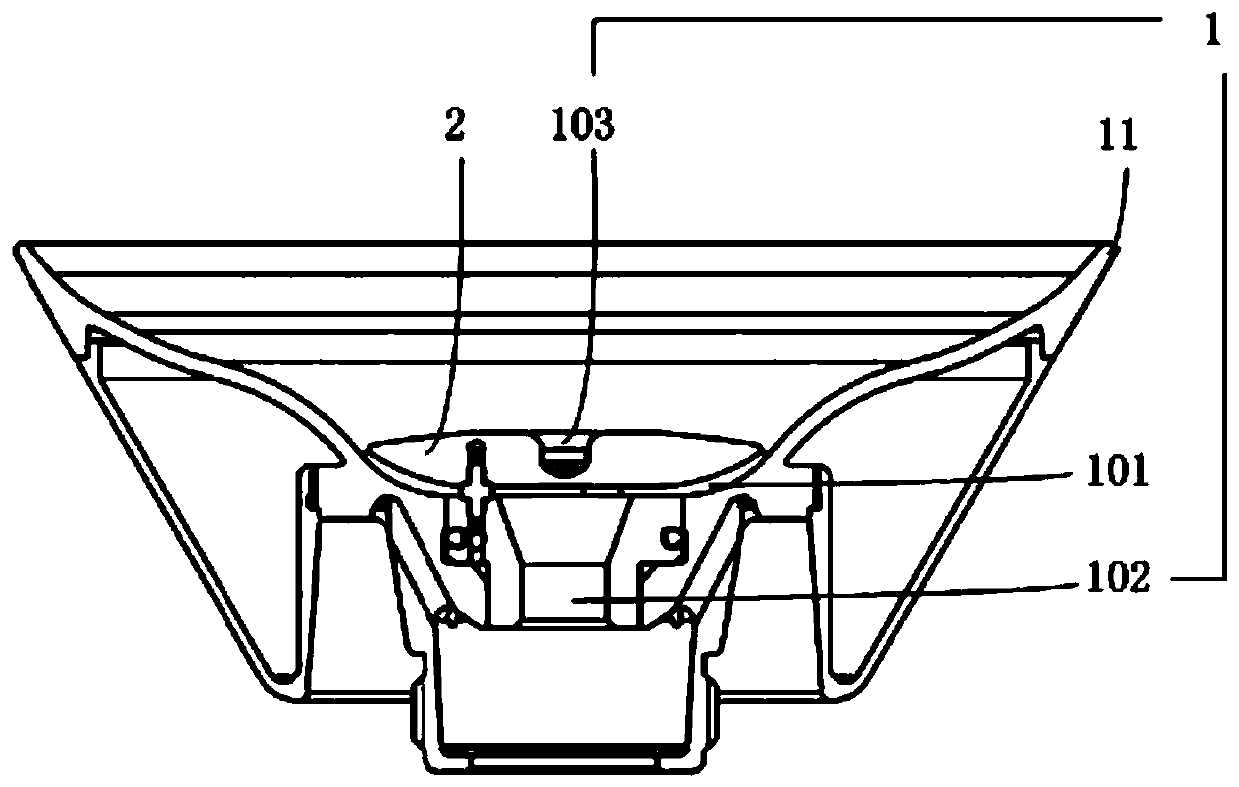

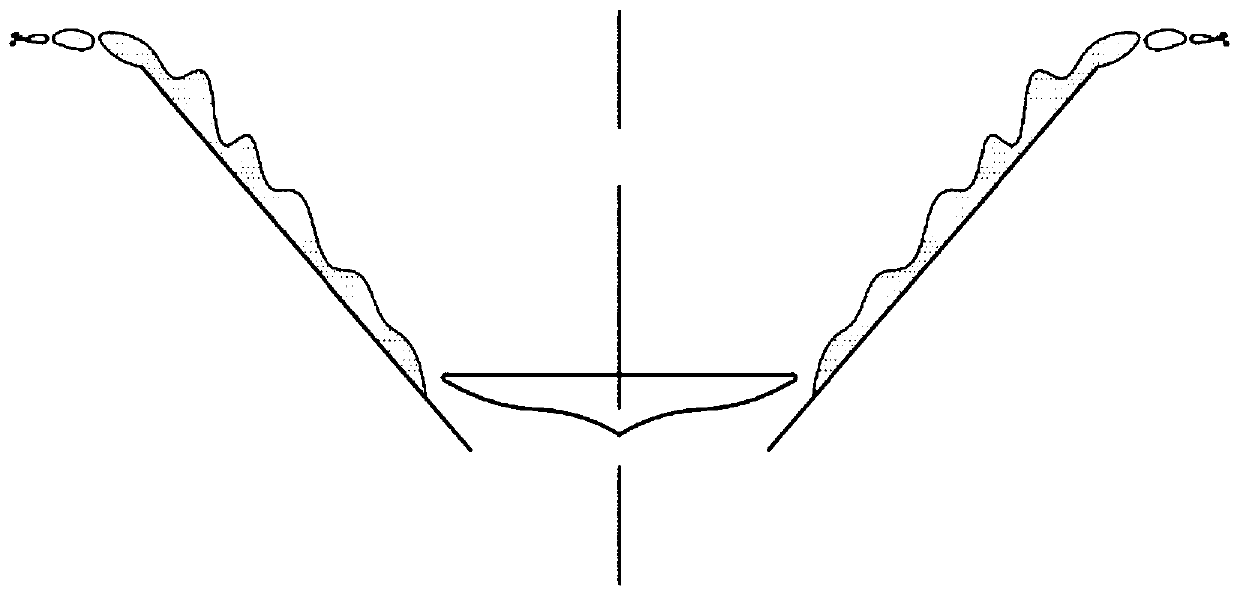

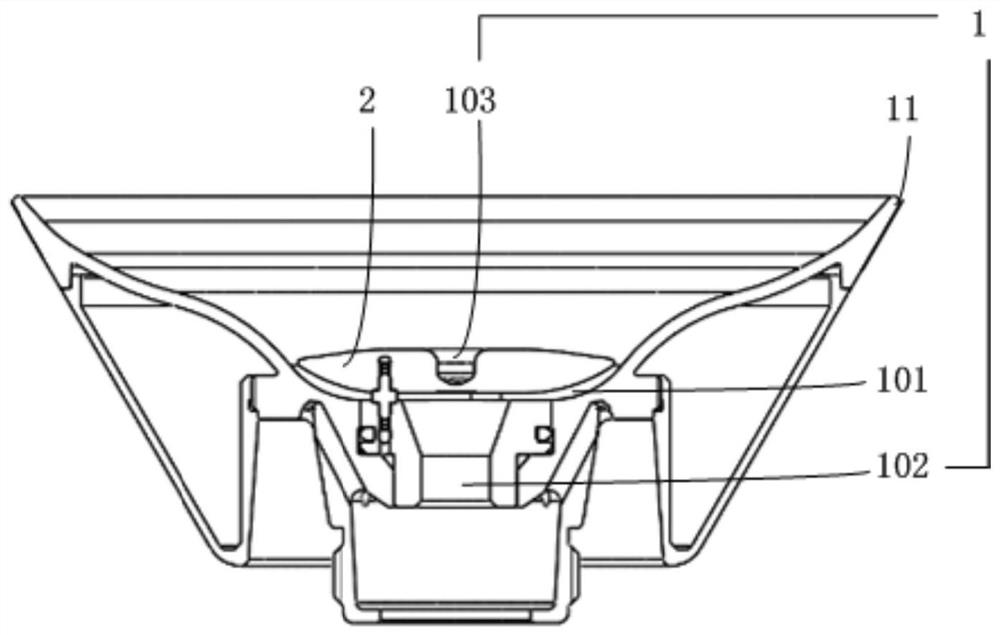

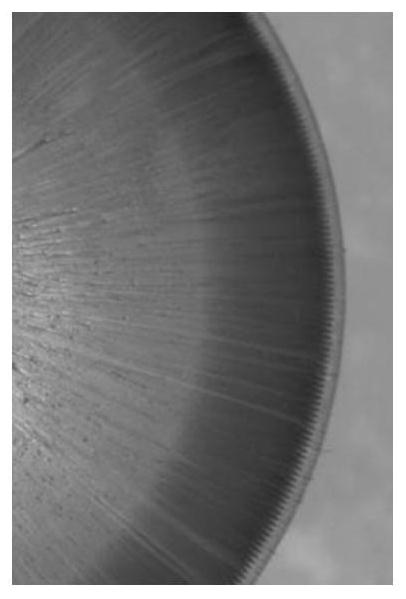

Atomizing bell head and electrostatic rotary bell atomizer

ActiveCN110841818AEliminate wavesImprove spraying effectLiquid spraying plantsSpray discharge apparatusMechanical engineeringPhysics

The invention discloses an atomizing bell head and an electrostatic rotary bell atomizer, and belongs to the field of painting. The atomizing bell head comprises a bell body and a distribution disc, the distribution disc is arranged in the bell body, moreover, a liquid filling cavity is formed between the lower surface of the distribution disc and the inner wall of the bell body, the bottom of thebell body is provided with a first liquid passage communicating with the liquid filling cavity, the center of the distribution disc is provided with a second liquid passage communicating with the liquid filling cavity, a gap is formed between the distribution disc and the inner wall of the bell body, so that when the bell body rotates and a liquid enters the liquid filling cavity, a part of the liquid rises to the bell edge of the bell body through the gap, the other part of the liquid flows through the upper surface of the distribution disc through the second liquid passage and then rises tothe bell edge of the bell body, the bell edge of the bell body is provided with fine teeth, the fine teeth are used for cutting the liquid, the curve forming the inner wall of the bell body through rotation is an inverse triangular cosine function curve y=arccox, wherein the y is the height of the bell body, and the x is the width of the bell body. According to the atomizing bell head and the electrostatic rotary bell atomizer, spraying effect and quality are improved.

Owner:CHERY AUTOMOBILE CO LTD

A kind of product closed end folding oblique shovel angle mold

ActiveCN107159793BEliminate convexityAvoid the phenomenon that the U-shaped rounded corners are bent and protrudedShaping toolsSlide plateEngineering

Owner:佛山市顺德区富润华模具有限公司

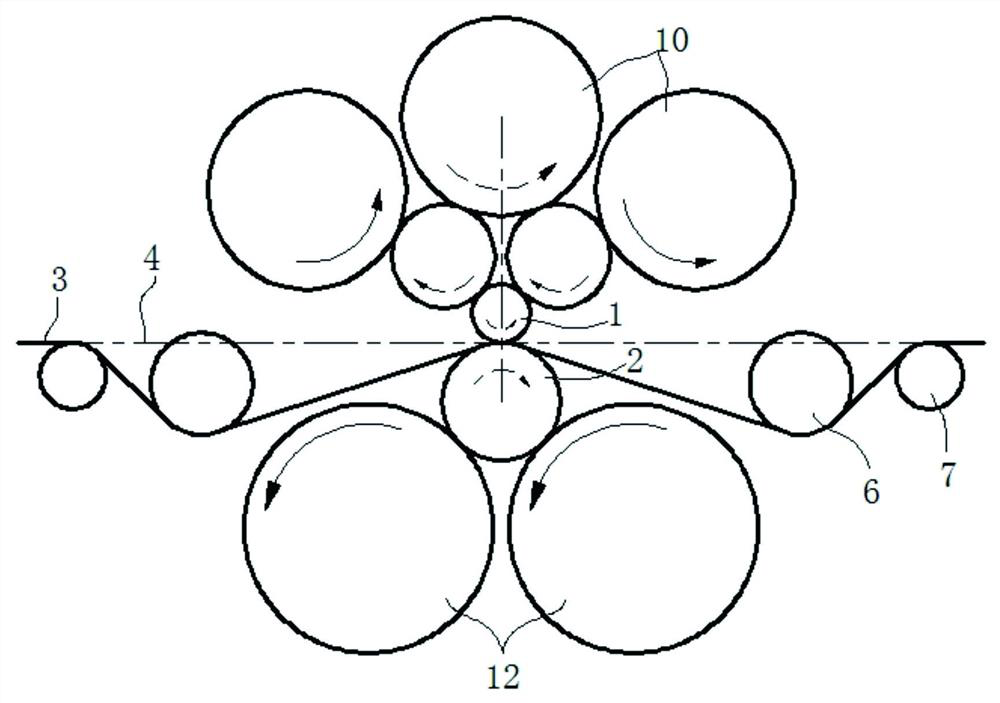

Belt flattening mechanism

ActiveCN102910477BThe edge position is accurateEliminate wavesElectrode manufacturing processesWebs handlingInductorPole piece

Owner:DONGGUAN ARECONN PRECISION MACHINERY

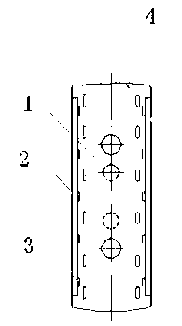

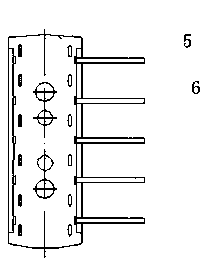

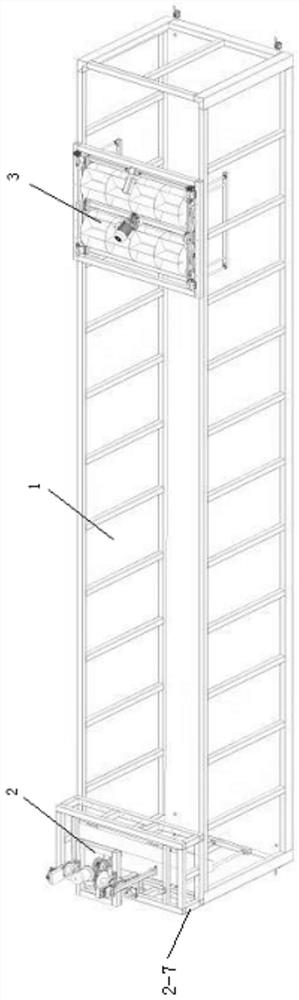

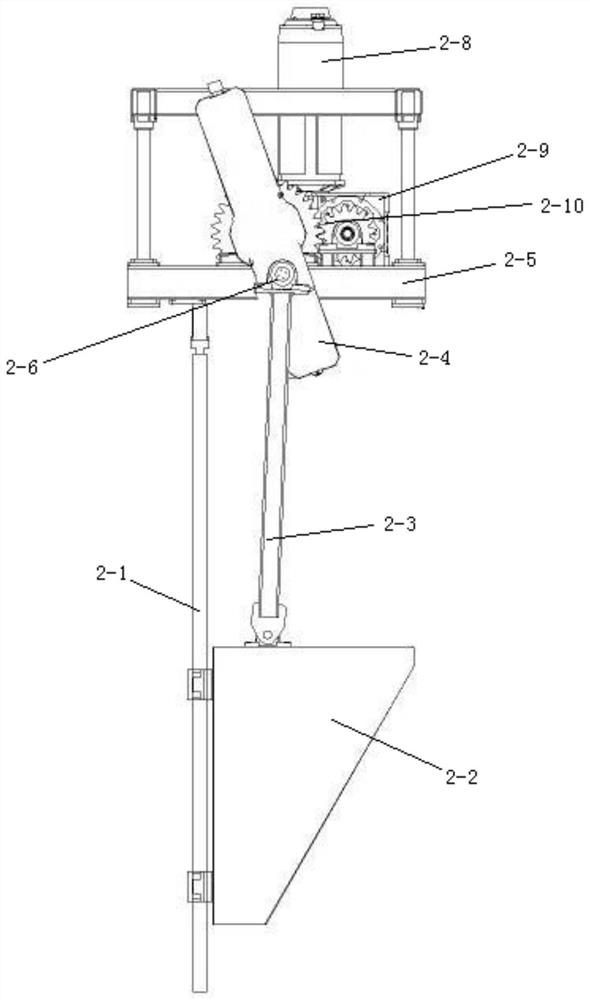

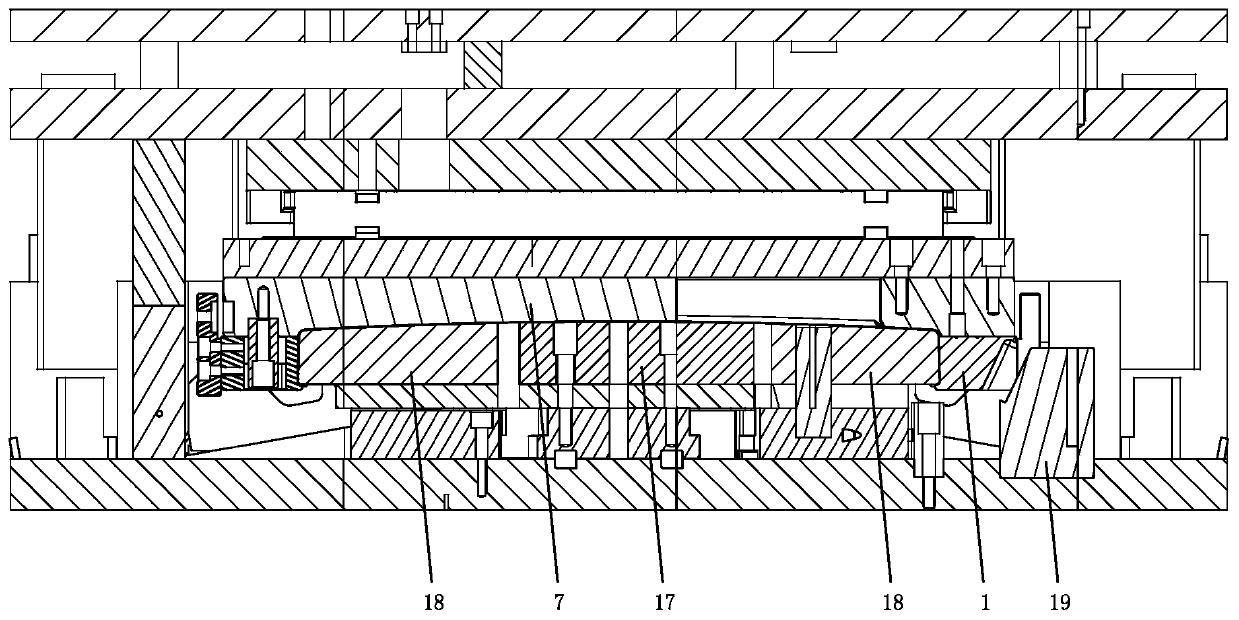

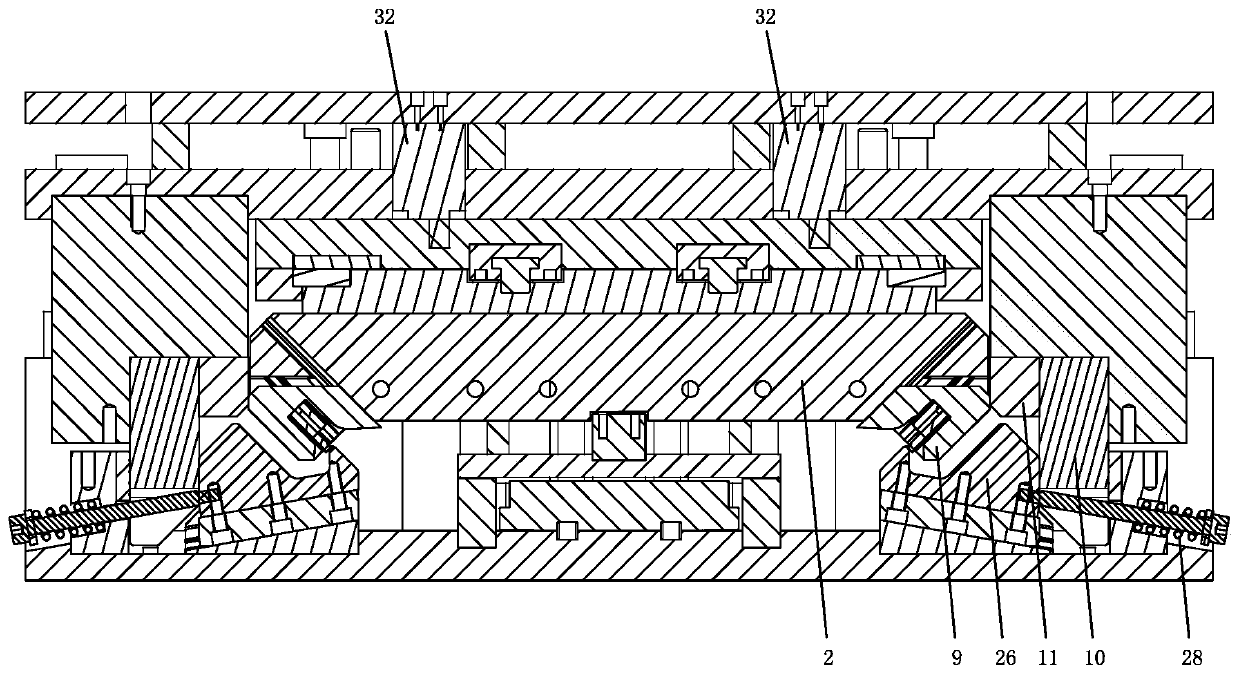

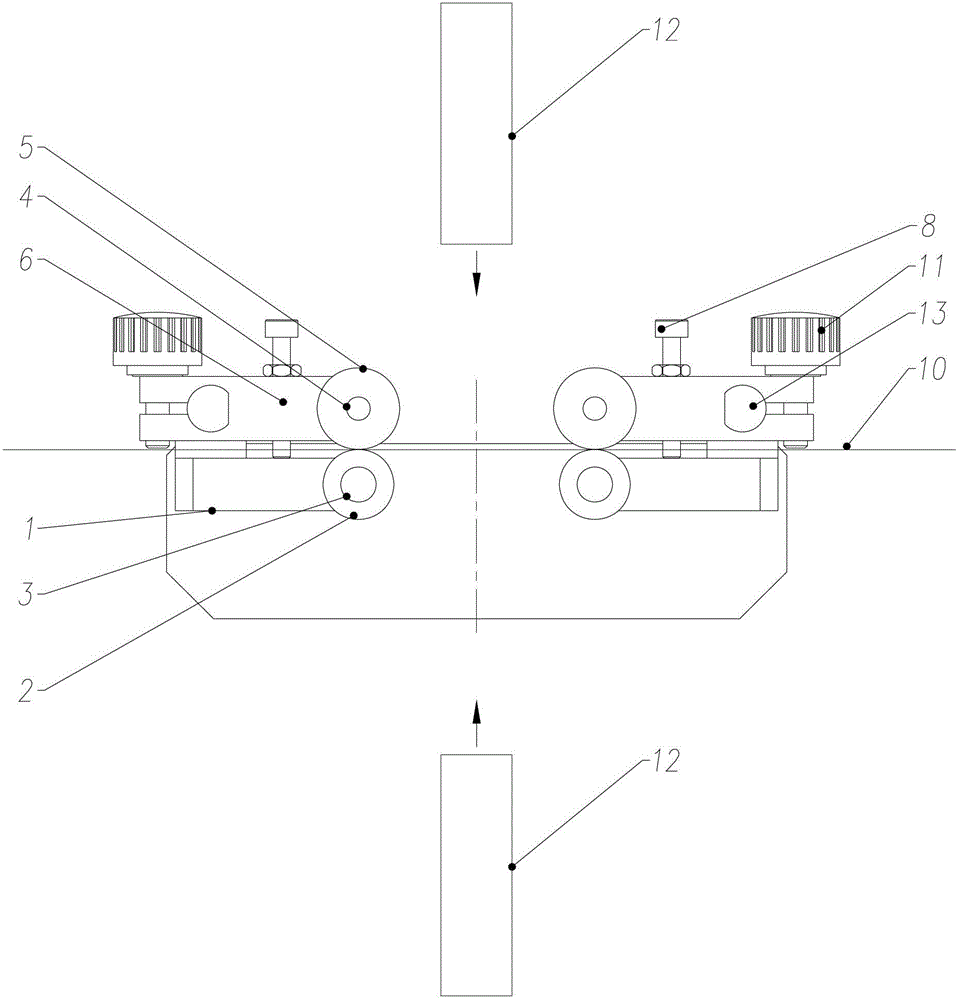

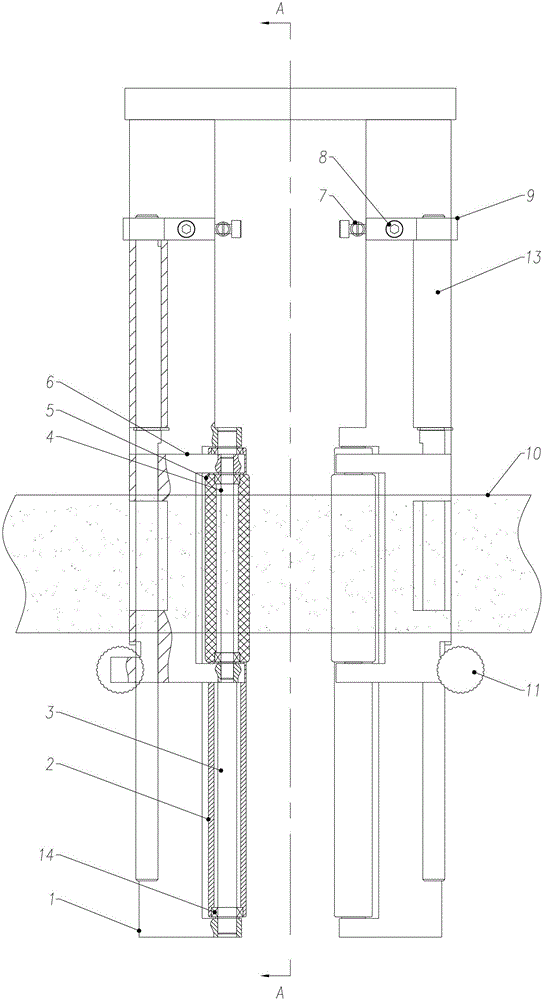

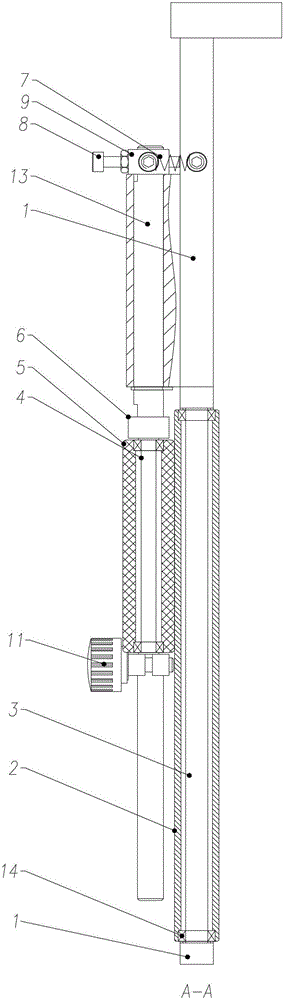

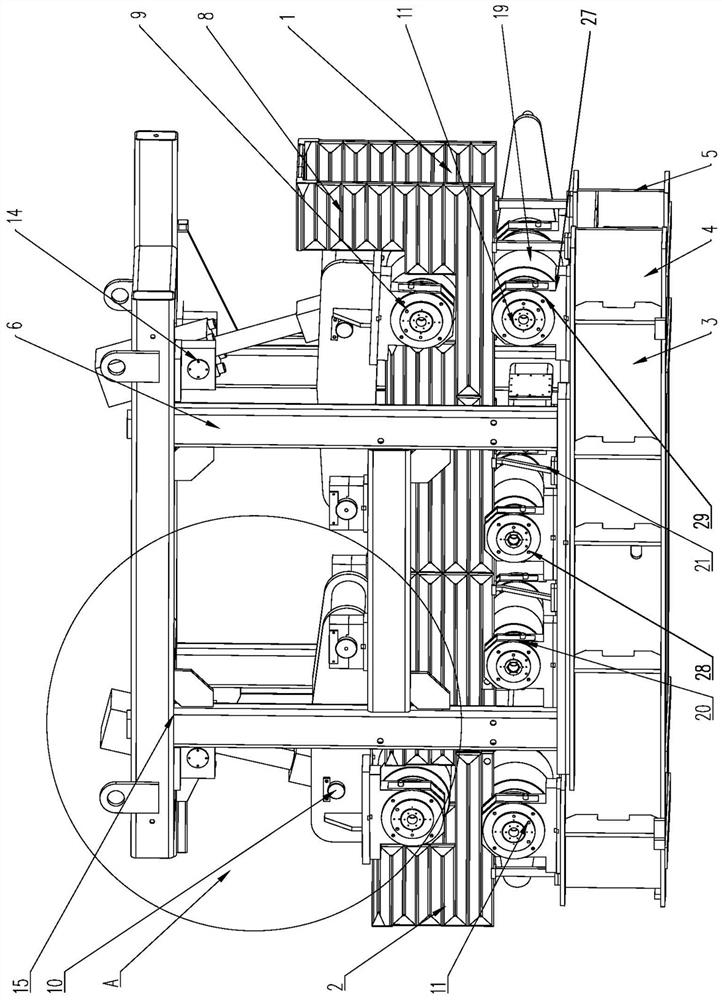

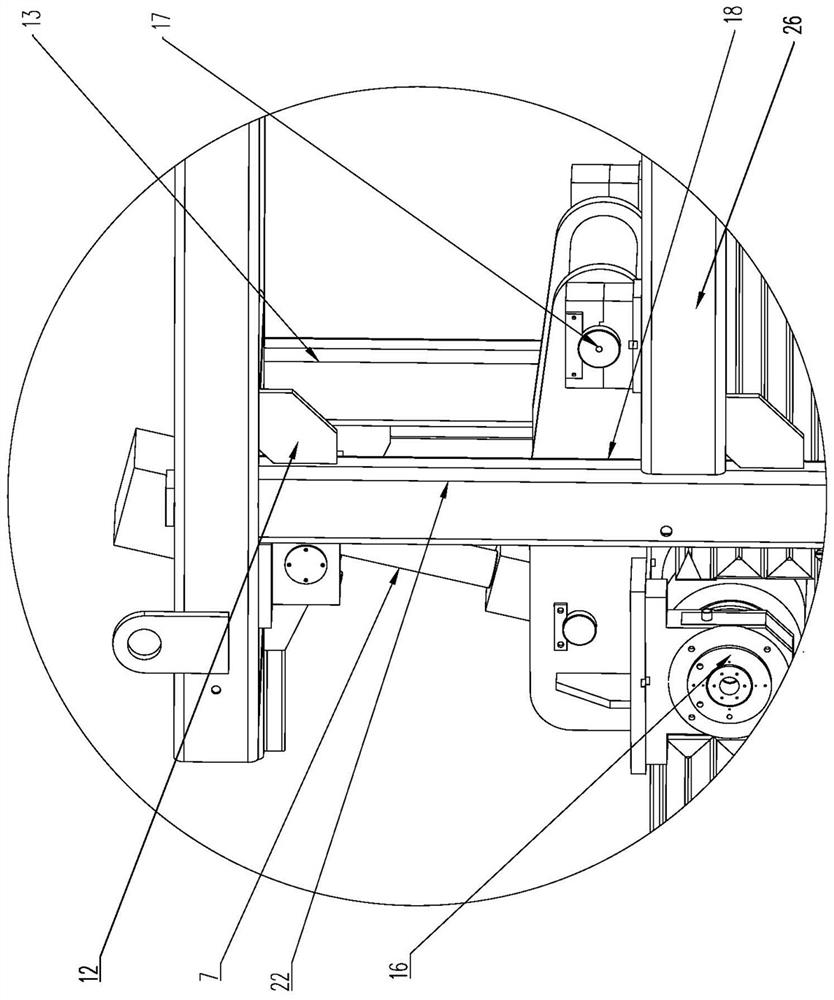

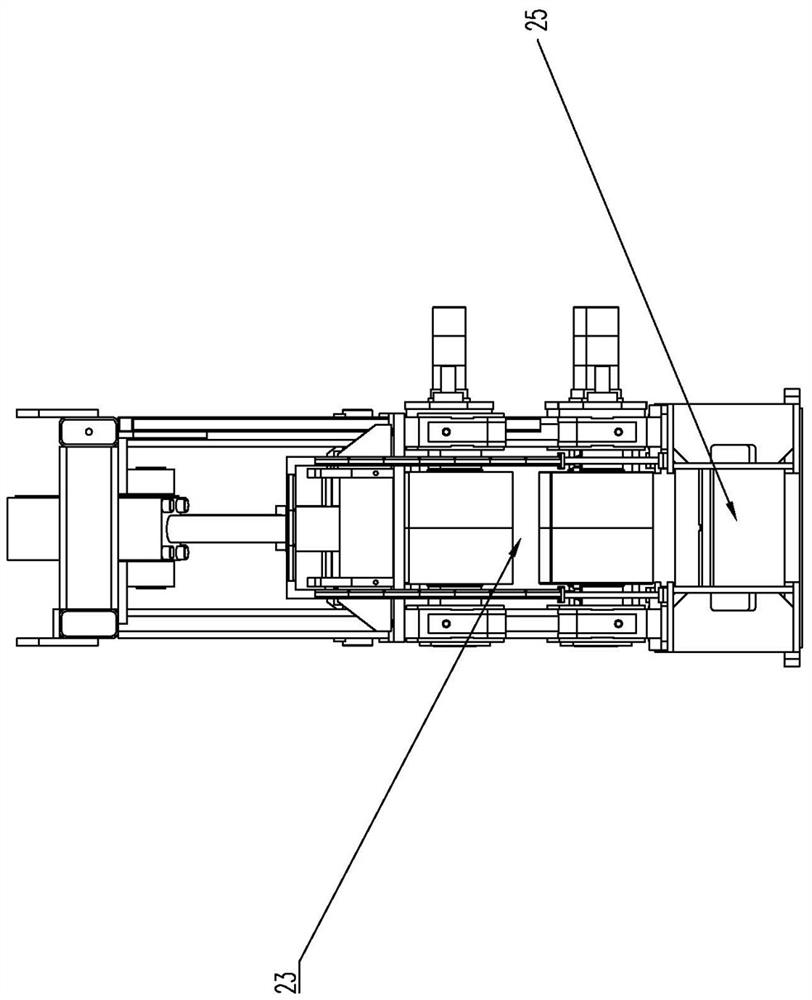

Novel withdrawal and straightening machine and working method of withdrawal and straightening machine

The invention relates to a novel withdrawal and straightening machine and a working method of the withdrawal and straightening machine in the field of metallurgical equipment. A baffle assembly is further arranged above the position from a feeding port in the front side of a base and a discharging port in the rear side of the base in a matched manner. The baffle assembly is fixedly installed on amiddle main supporting frame. A front side pressing adjusting assembly and a rear side pressing adjusting assembly are arranged on the front face and the rear face of the middle main supporting framecorrespondingly. The base is further provided with a lower pressing adjusting assembly matched with the front side pressing adjusting assembly and the rear side pressing adjusting assembly. A liftinglug is further arranged on the middle main supporting frame in a matched manner. According to the withdrawal and straightening machine provided by the invention, a good plate shape can be effectivelyand quickly produced through the withdrawal and straightening machine, and meanwhile, the defects of wavy edges, wavy shapes and the like of a plate surface can be eliminated, so that the straightnessof a thin plate is greatly improved; and meanwhile, the invention further provides the working method of the withdrawal and straightening machine, by means of the method, the working efficiency can be improved, lace defects are avoided, and therefore the rejection rate is reduced, and the stretching effect is greatly improved.

Owner:扬州江冶喷雾系统有限公司

Atomizing cup head and electrostatic rotary cup

ActiveCN110841818BEliminate wavesImprove spraying effectLiquid spraying plantsSpray discharge apparatusEngineeringMechanical engineering

The invention discloses an atomizing cup head and an electrostatic rotary cup, belonging to the field of painting. The atomizing cup head includes: a cup body and a distribution plate; the distribution plate is arranged in the cup body, and a liquid filling chamber is formed between the lower surface of the distribution plate and the inner wall of the cup body; the bottom of the cup body has a first Liquid channel, the center of the distribution plate has a second liquid channel that communicates with the liquid filling cavity; there is a gap between the distribution plate and the inner wall of the cup, so that when the cup rotates and the liquid enters the liquid filling cavity, a part of the liquid rises through the gap to the edge of the cup body, another part of the liquid flows through the upper surface of the distribution plate through the second liquid channel and rises to the edge of the cup body; the edge of the cup body has fine teeth, which are used to cut the liquid; rotate The curve forming the inner wall of the cup is an inverse trigonometric cosine function curve: y=arccosx, wherein, y is the height of the cup, and x is the width of the cup. The invention improves the spraying effect and quality.

Owner:CHERY AUTOMOBILE CO LTD

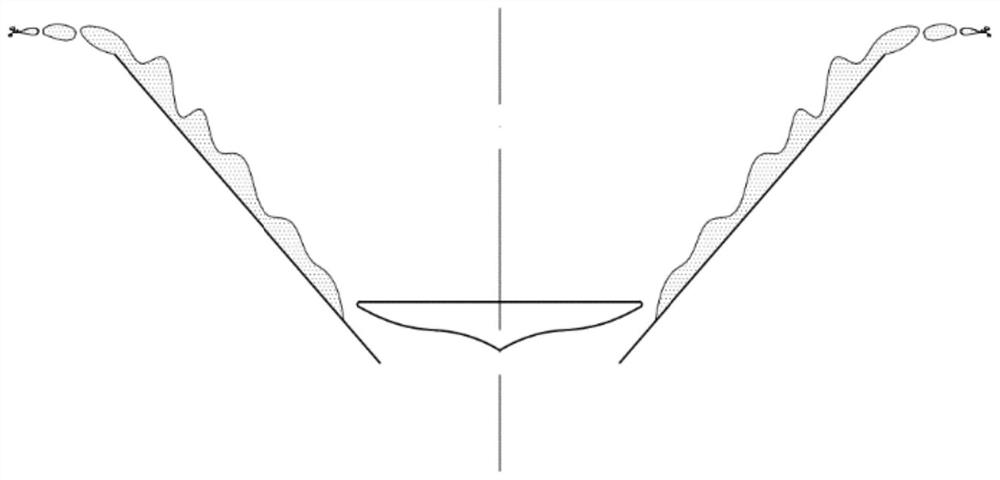

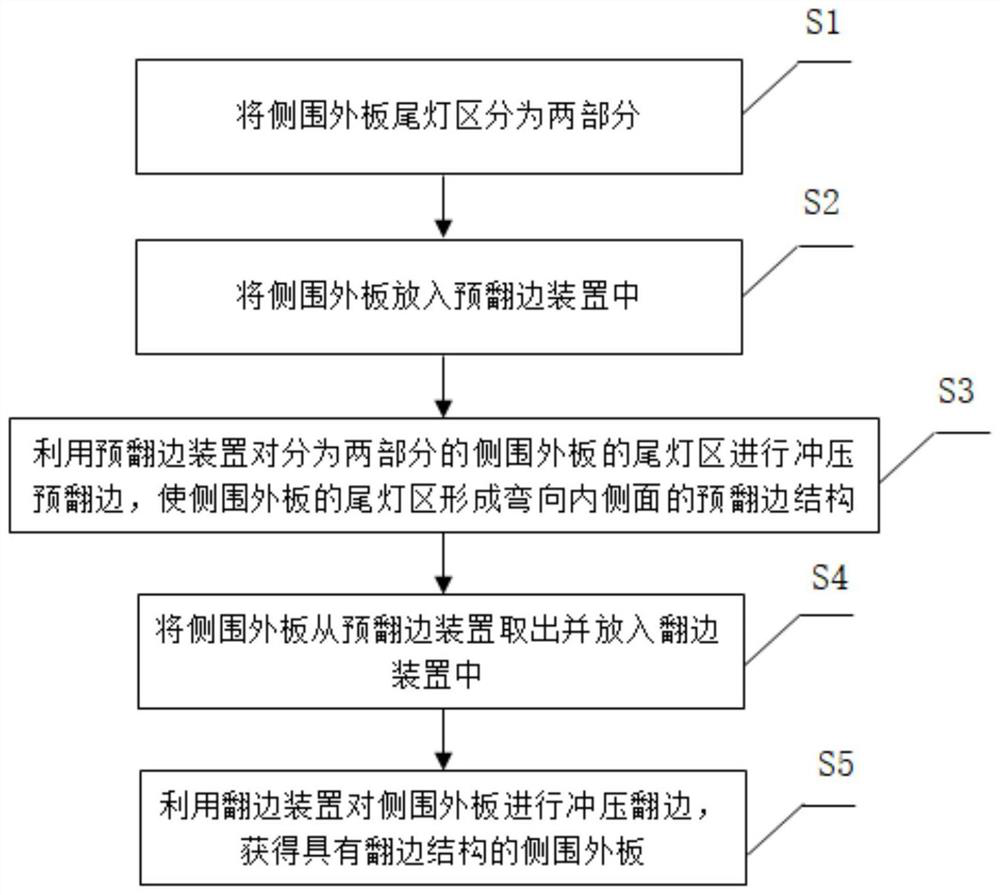

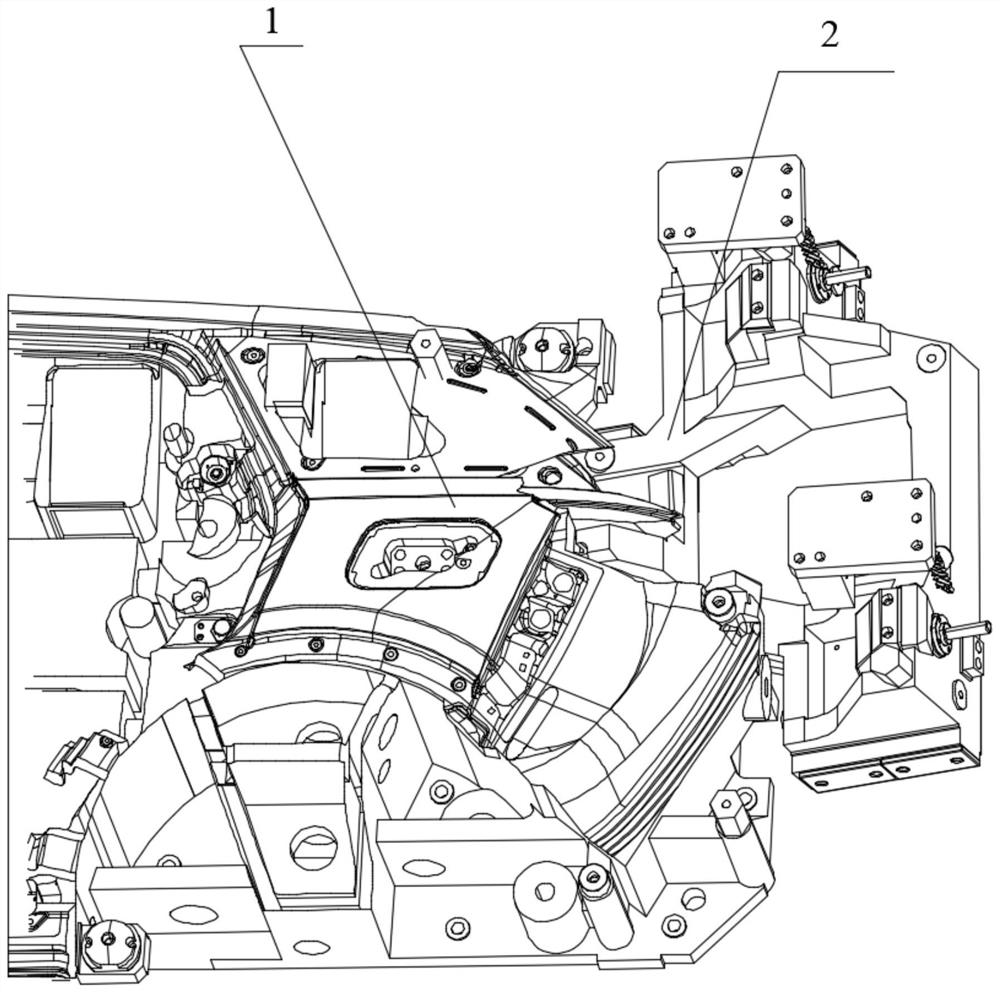

A flanging process and pre-flanging device

ActiveCN112338024BLighten the feed trendFeed trend eliminationShaping toolsVehicle componentsEngineeringFlange

The invention relates to the technical field of automobile cover molding, and discloses a flanging process and a pre-flange device, wherein the flanging process includes dividing the tail light area of the side wall outer panel into two parts; putting the side wall outer panel into the pre-flange In the device, the pre-flange device is used to stamp and pre-flange the taillight area of the side wall outer panel which is divided into two parts, so that the tail light area of the side wall outer panel forms a pre-flange structure bent to the inner side; the side wall outer panel The board is taken out from the pre-flange device and put into the flange device; the side wall outer panel is punched and flanged by using the flange device to obtain a side wall outer panel with a flange structure. Through the above method, the flanging process can reduce the material tendency of the side wall outer panel from the outer side, and help eliminate waves and dark pits on the outer side of the side wall outer panel in the tail light area.

Owner:CHINA FIRST AUTOMOBILE

Product closed end bending, chamfering and angle shoveling die

The invention relates to a product closed end bending, chamfering and angle shoveling die. The product closed end bending, chamfering and angle shoveling die comprises an upper die assembly and a lower die assembly which vertically correspond to each other. A compressing mechanism, an end bending mechanism and a side beating mechanism are arranged between the upper die module and the lower die module. The compressing mechanism comprises a drive male die, a side pressing male die, a side pressing plate, a sliding plate, a first upper wedge and a first lower wedge. The end bending mechanism comprises a side bending female die, an angle bending female die, a wrap angle female die, a second upper wedge and a third upper wedge. The side beating mechanism comprises a side beating wedge and a side beating drive block. The product closed end bending, chamfering and angle shoveling die has the beneficial effects that the angle bending female die moves in the direction of 45 degrees, surplus materials flow inwards, and the phenomenon that the U-shaped circular bead end is convexly bent outwards is completely avoided; a gap stepless variable structure is arranged, after end bending is carried out, a gap between a first flush surface and a second flush surface is equal to one time of material thickness, and the wave phenomenon is avoided; and the longitudinal motion of the drive male die is converted into the lateral motion of the side pressing male die, top damage is effectively avoided, and die removing is more convenient.

Owner:佛山市顺德区富润华模具有限公司

A Three-dimensional Triangular Wound Core Transformer Core Winding Mandrel

ActiveCN103280309BTight between slicesEliminate wavesTransformers/inductances detailsInductances/transformers/magnets manufactureTransformerMaterials science

The invention discloses an iron core winding core die for a transformer with a wound stereoscopic triangular iron core. The iron core winding core die comprises a body, iron bars separable from the body are arranged on two sides of the body, and a group of windows used for binding core limbs is arranged at the joint of the inner side of the iron bars and the body. The upper and lower end faces of the body are provided with radian. Iron chips wound by the core die are compact and non-wavy, and the iron core winding core die in combined structure facilitates binding and shaping of the core limbs after annealing, and iron core quality is greatly improved.

Owner:JIANG SU ZHONGRONG TECH

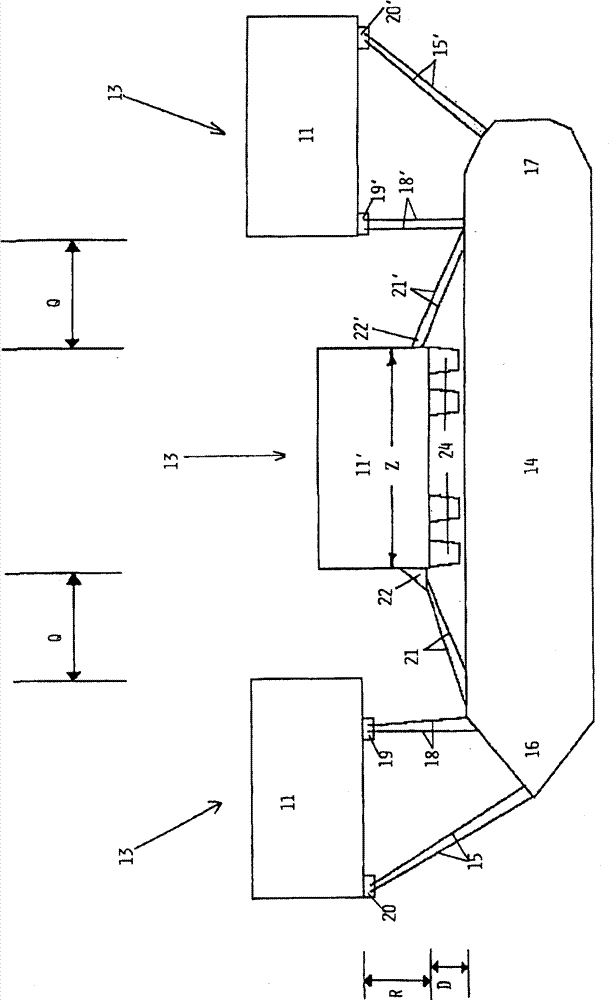

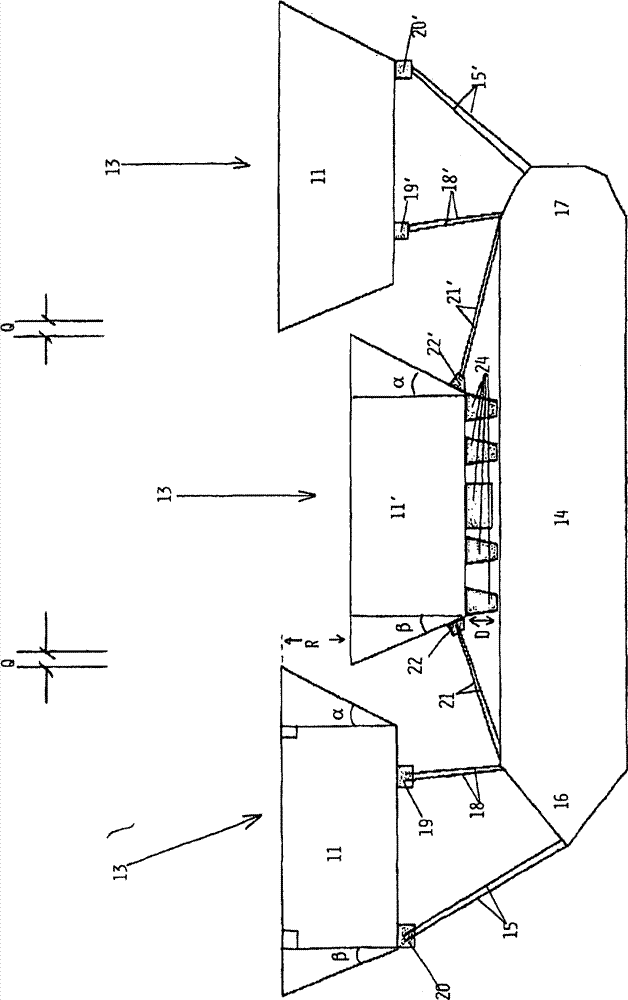

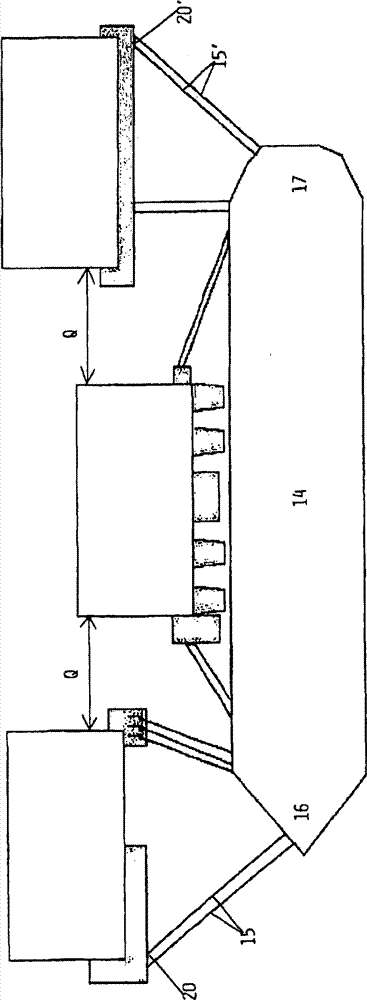

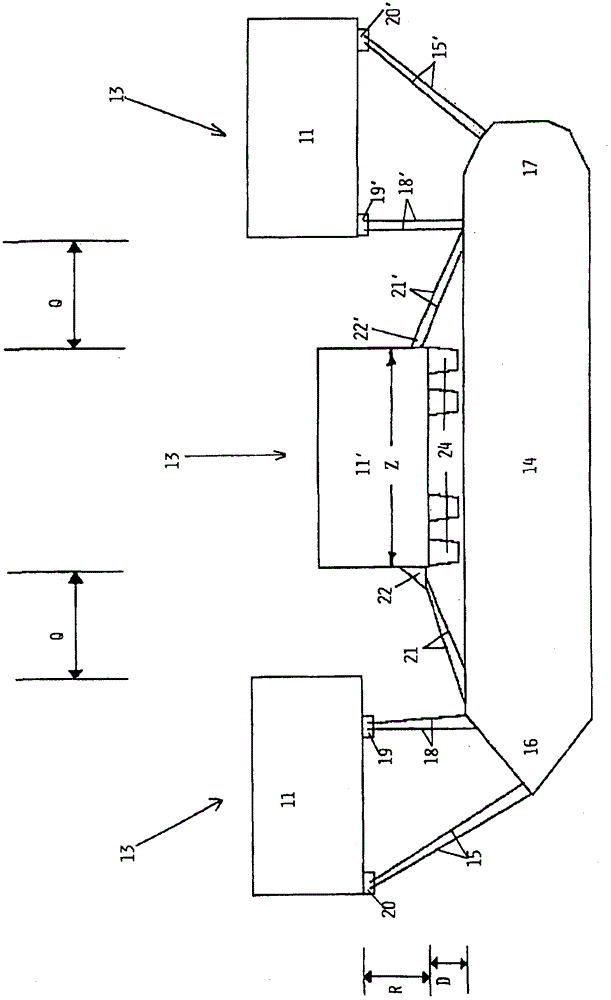

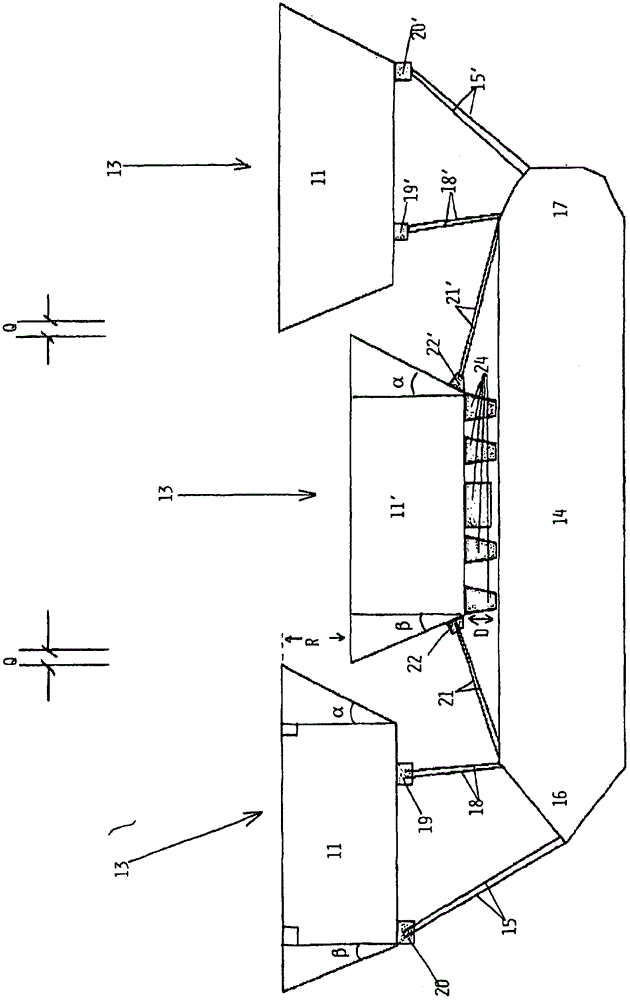

Facility and method for storing and offloading oil and gas

ActiveCN103946455BAvoid wave energy build-up effectsWave energy is avoided or at least significantly reducedBreakwatersWaterborne vesselsMarine engineeringWater flow

The present disclosure discloses a harbor facility (10) for storing, loading and unloading oil and gas products at sea, comprising a plurality of units (11, 11') arranged alternately on the seabed to form the harbor facility. The units (11, 11') are independently positioned at a given distance from the lateral direction and have front surfaces along which the vessel can be moored, thereby forming part of the wave channel, and configured to attenuate incoming waves while Allow waves and currents from other parts to pass through the harbor facility. The lateral distance between two adjacent units (11, 11') is controlled by the frequency of the waves to be damped and the waves allowed to pass between the units (11, 11'). In a transverse direction away from the incoming wave, the front surface of one of the units (11, 11') is offset by a distance relative to two adjacent front surfaces and / or the unit is configured to Increase or decrease the channel width between two adjacent units in the direction of motion.

Owner:GRAVIFLOAT AS

Special type veil base

The invention discloses a translucent screen, wherein, a screen base of the screen takes the structure of a plurality of layers or two layers and the layers of the screen base adhere to each other by adhesive materials. Because the concave and the convex formed by curliness of the screen for a long term can be stretched to be straight under the action of gravity after the screen is hung and unfolded and the local deformation of any screen base layer can be constrained by other layers, the breadth for fluctuation of the screen can be greatly reduced and then V-shaped waves are difficult to occur in the screen of the technical proposal, thereby the problem of smoothness of the translucent screen is well solved.

Owner:罗筱泠

Use of wave absorption water channel and a kind of-wave absorption water channel

InactiveCN1830509AEliminate wavesGood for jumping and flyingSport apparatusOceanographyWater channel

A wave eliminating water area used to play a water discus, which is disclosed by the Chinese patent No. 1830507, features that it is divided into a series of small water areas, and said water discus can continuously jump and fly from one small water area to another, so eliminating water wave.

Owner:吴举杰

On-line closed-loop control method for hot strip flatness

ActiveCN110653269BAchieving Quantitative ControlImprove flatness control accuracyMetal rolling arrangementsProfile control deviceLoop controlControl system

The invention relates to an online closed-loop control method for the flatness of hot continuous rolling strips, belonging to the technical field of electric automation control. The method executes the following steps: 1) When the strip arrives at the entrance of the finishing mill, the corresponding value is received; 2) Each frame is closed-loop controlled with the set value of bending force and speed to thread the strip; 3) The final machine is turned off 4) Calculate the time T; 5) Send the feedback value to the automatic control system; 6) According to the feedback value of strip flatness, flatness target value, flatness and bending force The conversion coefficient is used to calculate the size of the bending force of the end frame that needs to be adjusted; 7) The time T is the cycle to continuously read the feedback value, and the calculated adjustment value is used for accumulative control; 8) When the end frame throws steel, the end frame The calculation of the adjustment value of the bending force is completed, and the accumulated value is cleared. The method realizes the closed-loop adjustment of the bending force of the final frame according to the deviation of the flatness of the strip, greatly improves the control precision of the flatness of the strip, and improves the product quality.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

Rolling equipment and rolling method

ActiveCN113118214AAchieving spread rollingEliminate wavesMetal rolling stand detailsGuiding/positioning/aligning arrangementsPhysicsBack support

Rolling equipment comprises a rolling mill and an adjusting roller set. The rolling mill adopts a rolling scheme of working rollers with unequal diameters, so that the thinning of foil is generally facilitated, and a better plate shape is also favorably obtained; and the rolling mill adopts an asymmetric roller system, so that the number of rollers is reduced, the precision of the roller system is favorably improved, and the rollers are convenient to adjust and maintain. The adjusting roller set adopts oil blocking rollers and flattening rollers which are unequal in diameter, the flattening function and the oil blocking function are both considered, the oil blocking rollers with the smaller roller diameter are beneficial to squeezing away redundant lubricating oil, and the flattening rollers with the larger roller diameter are beneficial to reducing the original defects of the foil. According to the rolling method, the height of the flattening rollers is adjusted, the foil is wrapped on the roller surface of the working roller with the larger roller diameter to form a wrapping arc, and tension is evenly distributed on the cross section of the foil through back supporting of the working roller on the foil; and the defects are eliminated in the key forming initial stage of rolling, and the plate shape is stabilized in the later stage of rolling forming, so that high-precision rolling of the wide foil is achieved.

Owner:SHANGHAI WUXING COPPER CO LTD +1

Process and apparatus for enriching aquatic micro algae

InactiveCN100371434CPromote enrichmentEasy to captureUnicellular algaeHarvestersEngineeringSewage treatment

Owner:KUNMING UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com