Rolling equipment and rolling method

A technology of rolling equipment and rolls, which is applied in the field of rolling mills, can solve the problems of large lateral force component of rolling force, large lateral bending tendency, and large biting angle of foil 3, so as to increase rigidity, improve lubrication conditions, Effect of reducing rolling defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] A rolling equipment used for high-precision rolling of copper foil with a thickness of 0.1mm and a width of 1000mm. The rolling equipment includes a rolling mill and a set of adjustment rolls, which will be described in detail below.

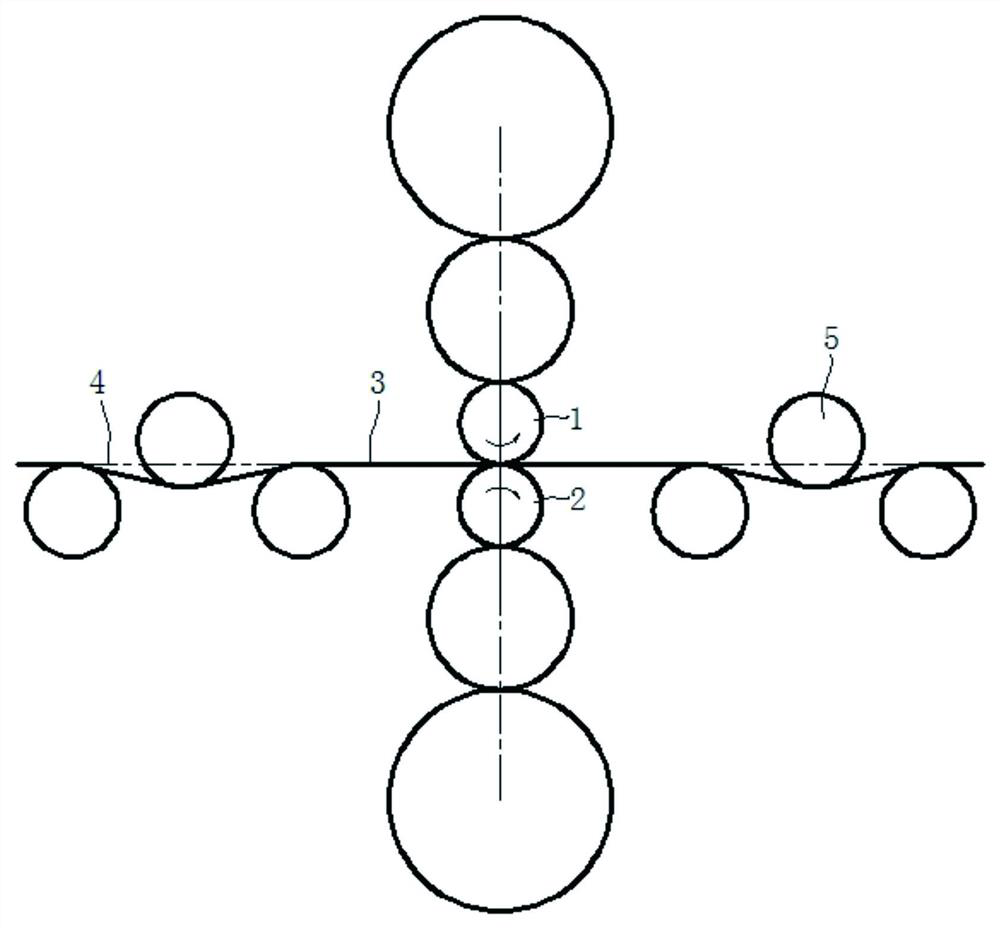

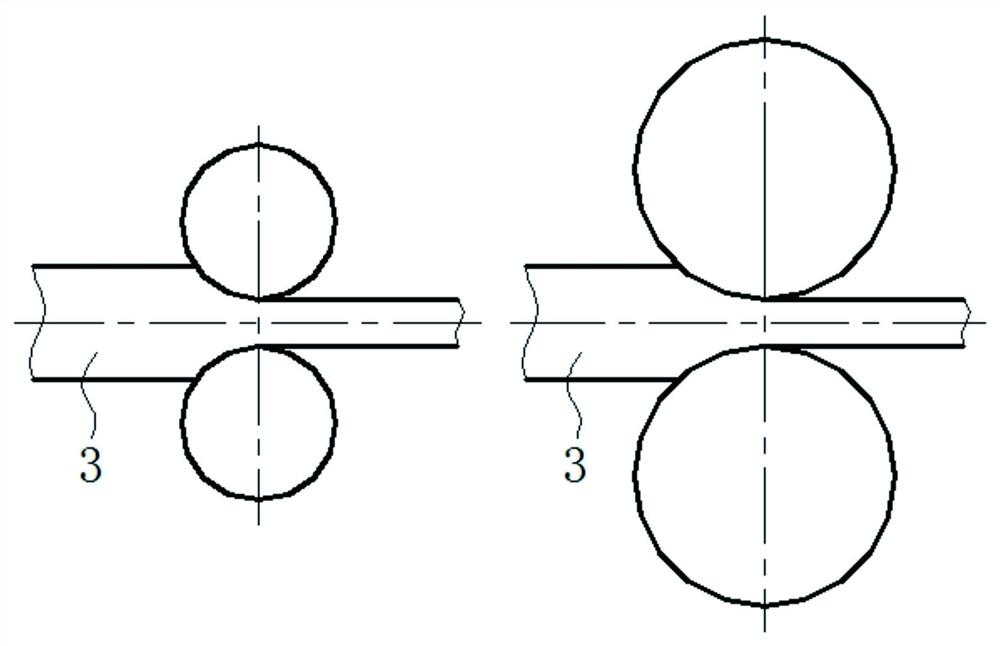

[0044] Such as image 3 As shown, the rolling mill used is a nine-roll rolling mill, and the rolls of the rolling mill are bounded by the rolling center line 4, and are divided into an upper half-roll system and a lower half-roll system, wherein the lower half-roll system consists of a lower work roll 2 and two The lower oblique pressure support roll 12 is formed, and the lower oblique pressure support roll 12 is used to press the lower work roll 2 , and the roll diameter of the lower oblique pressure support roll 12 is larger than that of the lower work roll 2 . The upper half roll system is composed of one upper working roll 1 and five upper oblique support rolls 10 . The roll diameter of the upper work roll 1 in the upper half roll s...

Embodiment 2

[0060] The difference between this embodiment and Embodiment 1 is that it is used for rolling copper foil materials with a thickness of 0.03 mm and a width of 800 mm. Due to the reduction in the thickness of the copper foil, it is necessary to use a smaller diameter upper work roll. In this embodiment, the roll diameter of the upper work roll 1 in the upper half roll set is 60 mm, the structure of the lower half roll set remains unchanged, the roll diameter of the lower work roll 2 in the lower half roll set is still 200 mm, and the lower work roll 2 is still 200 mm in diameter. The roll diameter of the roll 2 is approximately 3.3 times the roll diameter of the upper work roll 1 .

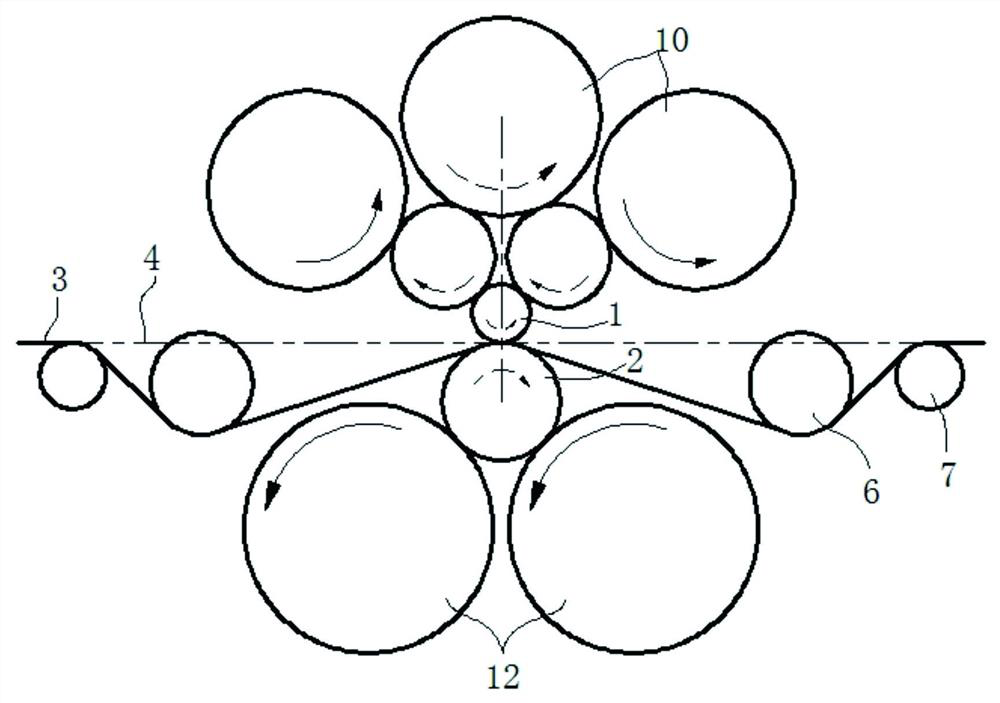

[0061] In order to make up for the lack of rigidity caused by the reduction of the diameter of the upper work roll 1, such as Figure 10 As shown, the rolling mill used is a thirteen-high rolling mill, and the structure of the lower half of the rolling mill is unchanged, while the upper half of th...

Embodiment 3

[0064] In this embodiment, the rolling mill is a nine-high rolling mill. Such as Figure 11 As shown, the upper half roll system of the rolling mill is the same as the upper half roll system in Example 1, the number of rolls in the lower half roll system is also three, and the roll diameter of the lower work roll 2 is still 2 times that of the upper work roll 1. times. The difference from Example 1 is that the lower half roll system is composed of a lower working roll 2 arranged in a straight line, a lower direct pressure backup roll 11 with a small roll diameter and a lower direct pressure backup roll 11 with a large roll diameter , wherein the lower direct pressure backup roll 11 with a small roll diameter is used to press the lower work roll 2, and the lower direct pressure backup roll 11 with a large roll diameter is used to press the lower direct pressure backup roll 11 with a small roll diameter. The flattening rolls 6 can be brought closer to the work rolls due to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com