Method for setting process parameters of stainless steel strip steel withdrawal and straightening machine unit

A technology of process parameters and setting methods, which is applied in the field of cold-rolled plate shape correction, can solve problems such as the impact of strip steel production quality, lack of targeted solutions, and plate shape wave shape, and achieve the elimination of wave shape and Effects of warping plate shape defects, solving process parameter inconsistencies, and improving strip quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

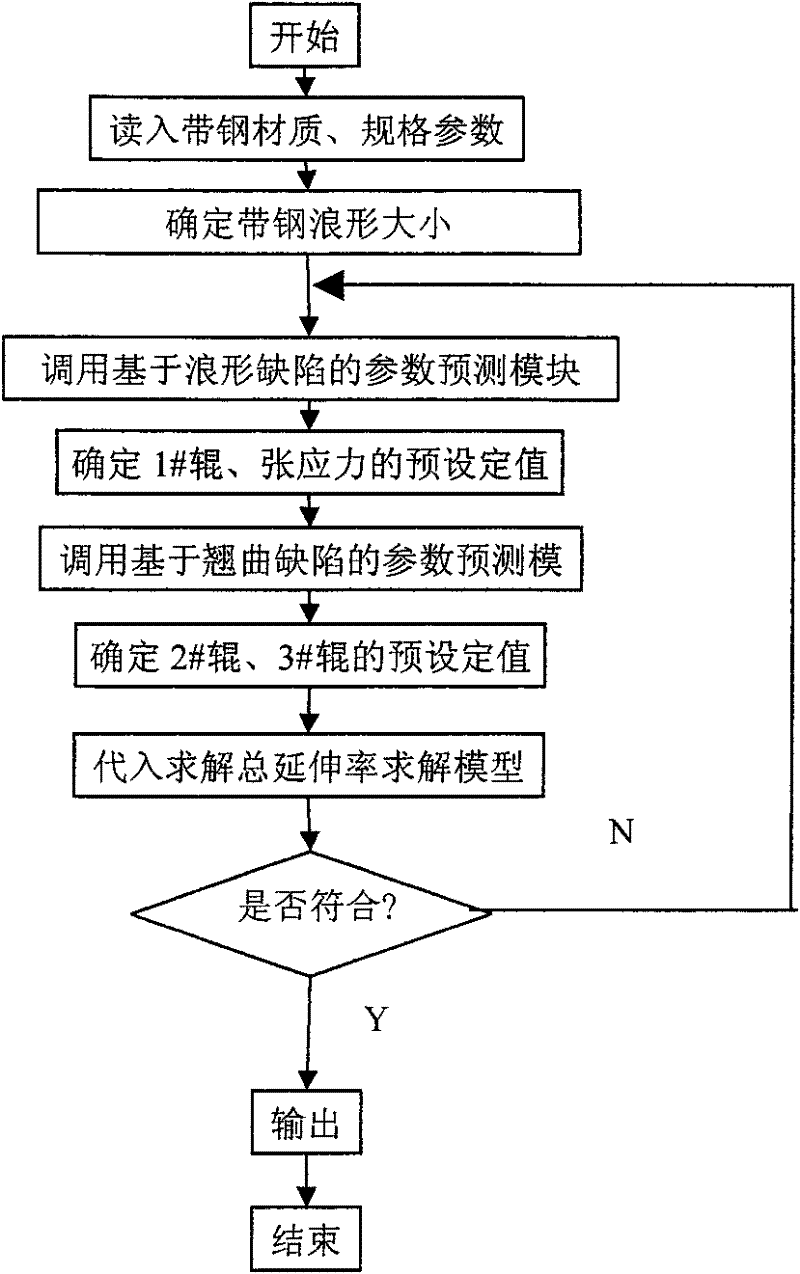

[0045] A process parameter setting method of a stainless steel strip tension leveler unit, the flow chart is as follows figure 1 As shown, the steps are:

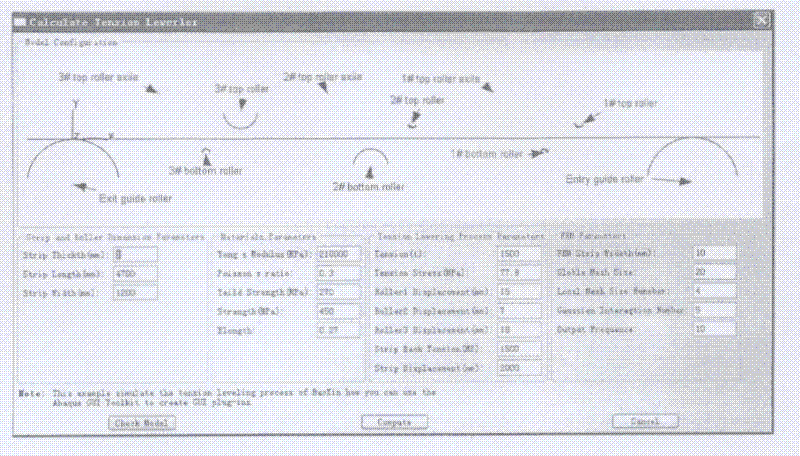

[0046]A. According to the specific structure and size parameters of the tension leveling machine, use finite element software to model, including pre-processing and working under a large number of different strip specifications, strip material parameters, process parameters, grid size parameters and other parameters Calculate and analyze the status data, and use the principle of stepwise regression to obtain the relationship between the elongation rate of the strip steel outlet and various process parameters, that is, the prediction model of the tension and leveling process parameters based on wave-shaped defects, determine the insertion depth and tension value of the 1# roll, and prelimin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| surface | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com