Method for detecting service life of tensioned dry method uniaxial tension diaphragm

A detection method and unidirectional stretching technology, applied in the direction of applying stable tension/pressure to test the strength of materials, measuring devices, instruments, etc., can solve problems such as increasing uncertainty, and achieve a simple detection device and simple detection operation process. , the effect of high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example

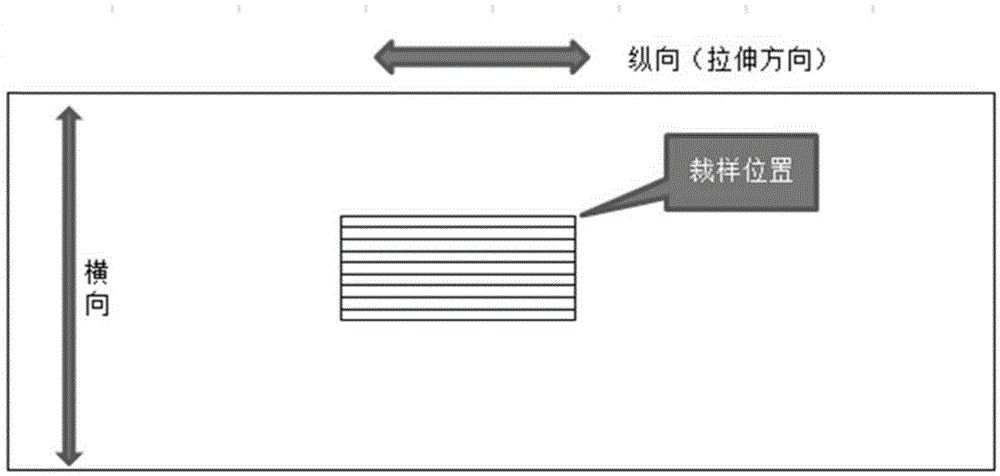

[0032] a. Take a sample of the 16μ product that has just been stretched, and the length of the pulled out diaphragm is about 2m; use the cutting equipment to cut the sample strip longitudinally along the stretching direction, the width of the sample strip is 15mm, and the number is 10;

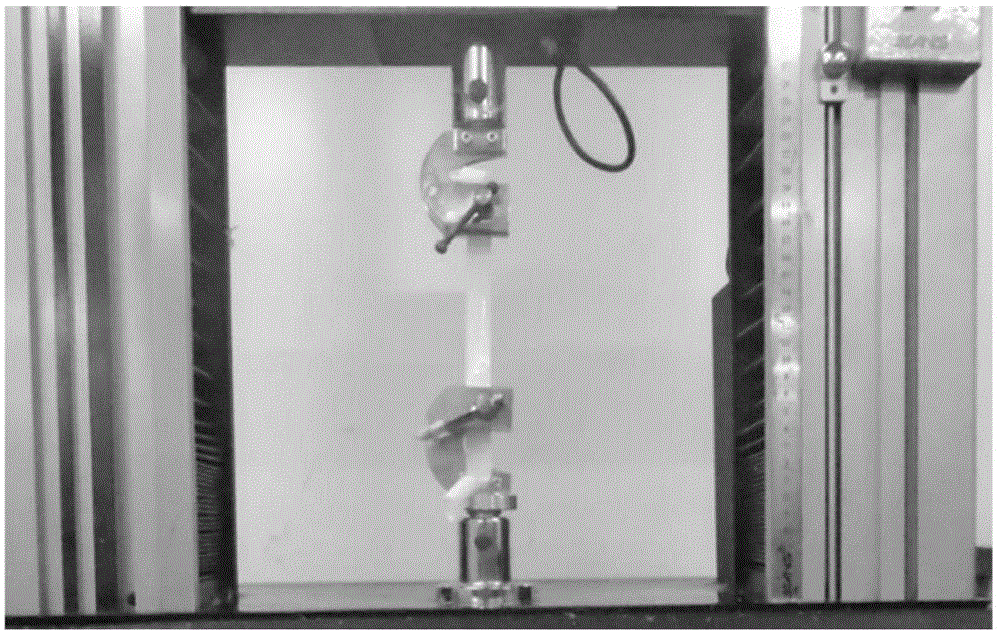

[0033] b. Take a sample and use the Xinsansi tensile testing machine to clamp both sides of the sample with clamps. The length of the sample between the clamps is 100mm.

[0034] c. Set the stretching length to 5mm, and maintain this stretching position, and record the change of stretching tension during this process by the computer connected to the tensile testing machine, and the recording time is 30min;

[0035] d. Take the splines in step a every 6 hours, and repeat steps b and c;

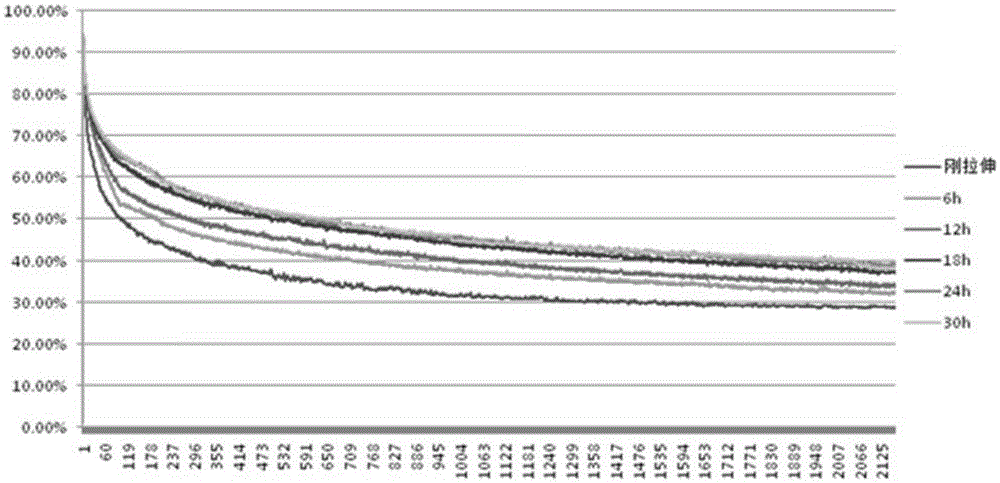

[0036] e. Obtain 6 tension curves and compare the results until such figure 1 As shown, the two tension curves basically coincide.

[0037] Depend on figure 1 It can be seen that the stress relaxation curves...

Embodiment 2

[0039] The following are specific implementation cases of this method:

[0040] a. Take a layer sample of the 32μ product that has just been stretched, and the length of the pulled out diaphragm is about 3m; use a sample cutting device to cut the sample along the longitudinal direction of the stretching direction, the width of the sample is 10mm, and the number is 5;

[0041] b. Take a sample and use the Xinsansi tensile testing machine to clamp both sides of the sample with clamps. The length of the sample between the clamps is 150mm.

[0042] c. Set the stretching length to 5mm, and maintain this stretching position, and record the change of stretching tension during this process by the computer connected to the tensile testing machine, and the recording time is 10 minutes;

[0043] d. Take the splines in step a every 0.5h, and repeat steps b and c;

[0044] e. Obtain 6 tension curves until the two tension curves basically coincide.

Embodiment 3

[0046] The following are specific implementation cases of this method:

[0047] a. Take a sample of the 50μ product that has just been stretched, and the length of the pulled-out diaphragm is about 2m; use the cutting equipment to cut the sample along the longitudinal direction of the stretching direction, the width of the sample is 20mm, and the number is 10;

[0048] b. Take a sample and use the Xinsansi tensile testing machine to clamp both sides of the sample with clamps. The length of the sample between the clamps is 200mm.

[0049] c. Set the stretching length to 5mm, and maintain this stretching position, and record the change of stretching tension during this process by the computer connected to the tensile testing machine, and the recording time is 60min;

[0050] d. Take the splines in step a every 12 hours, and repeat steps b and c;

[0051] e. Obtain 6 tension curves until the two tension curves basically coincide.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com