Plant for storage and unloading hydrocarbon and also a method thereof

A facility, oil and gas technology, applied to facilities and fields for storing and unloading oil and gas, can solve the problem of increasing ship movement, achieve the effect of avoiding wave energy accumulation effect, reducing wave energy, and less risk of installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0086] It should be noted that in the following detailed description of the embodiments shown in the drawings, the same reference numerals are used for the same or similar structures and features.

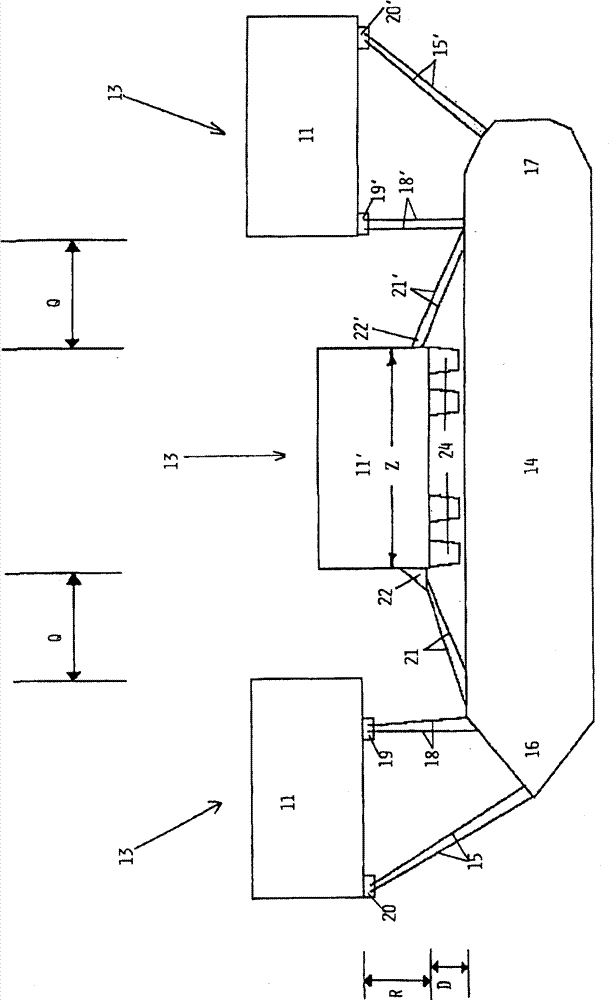

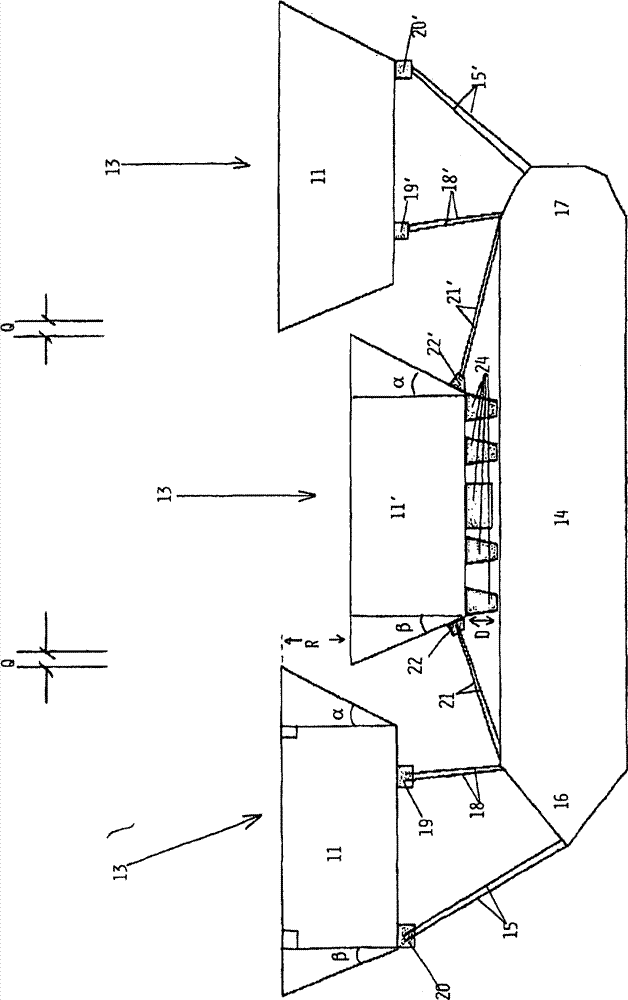

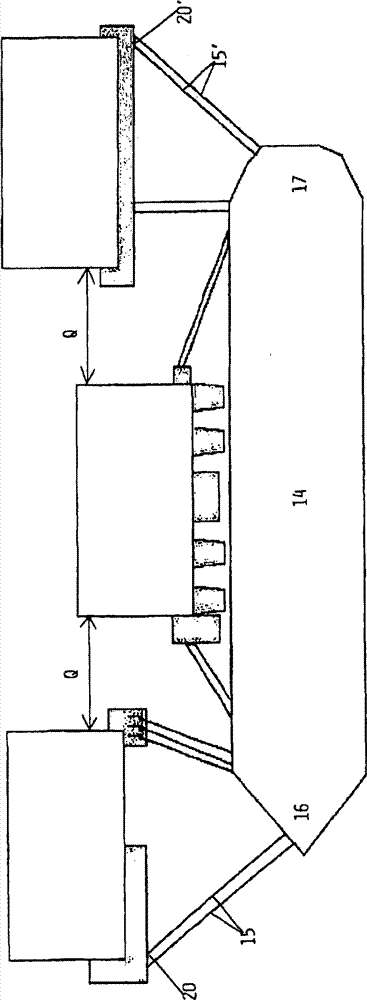

[0087] figure 1 A top view of an embodiment of a harbor station 10 according to the invention is schematically shown. The shown harbor site comprises three identical units 11, 11' configured to remain stably on the seabed 12 due to gravity. Three units 11, 11' are placed on the seabed 12 at a distance Q apart, the middle unit 11' is also positioned in a retracted position relative to the two other units 11, with a retracted distance R, the middle unit 11 ' are retracted in the same direction as the general principal direction 13 of the wave. as further shown in figure 1 , the vessel 14 is moored along the intermediate unit 11' on the leeward side of the units 11, 11'. The mooring system used to moor the vessel 14 to the units 11, 11' comprises one or more forward mooring l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com